Ketoconazole foaming agent and preparation method thereof

A technology of foam agent and ketoconazole drug, applied in the field of pharmacy, can solve problems such as difficult control, high cost, strong toxicity, etc., and achieve the effect of avoiding adverse conditions and good foam effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

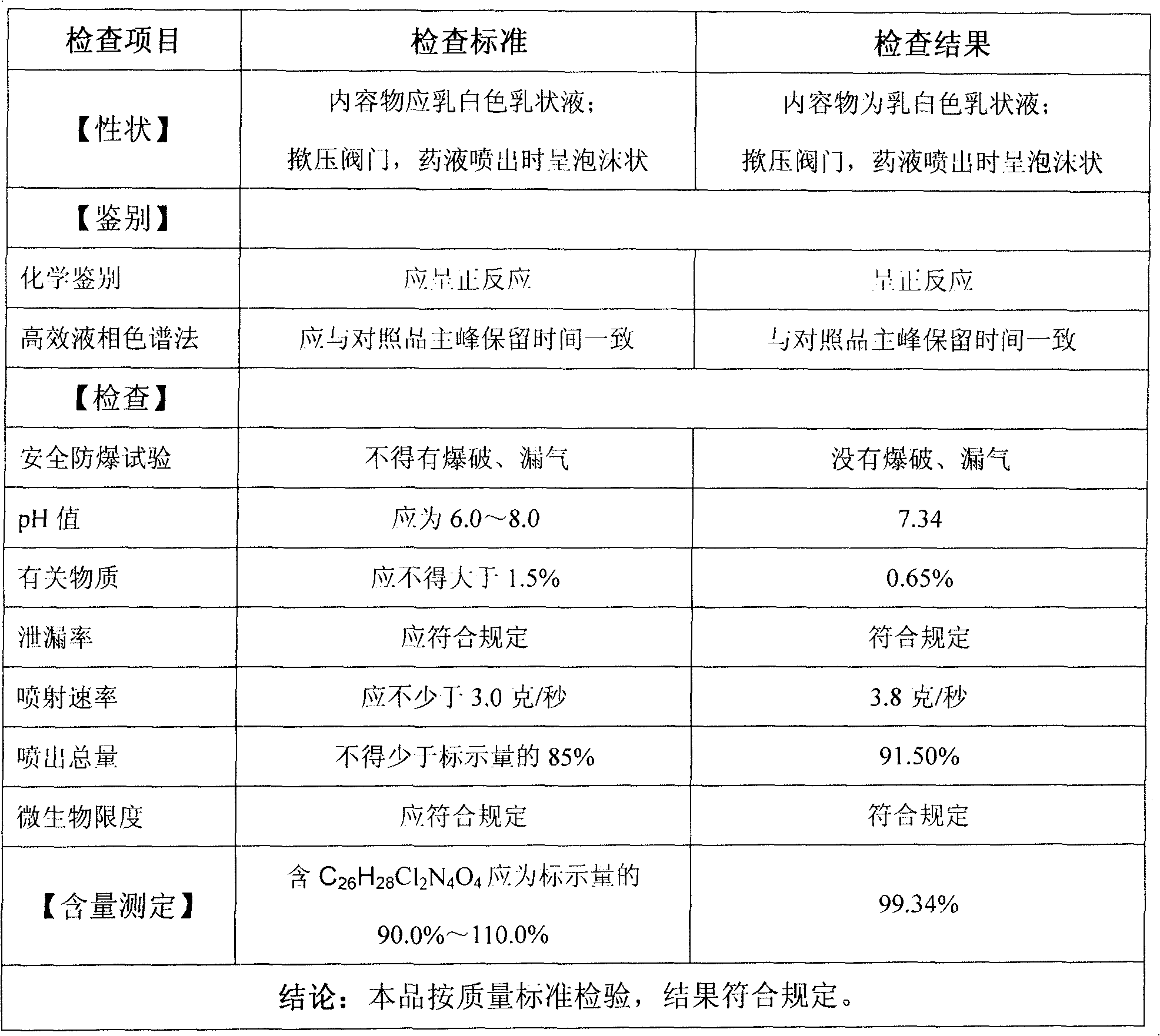

Image

Examples

Embodiment 1

[0029] Weigh absolute ethanol and propylene glycol and mix them uniformly as a solvent, keep the temperature at 50-60°C, and set aside.

[0030] Add stearyl alcohol, stir at 60°C to dissolve completely, keep the temperature at 50-60°C, and set aside.

[0031] Weigh ketoconazole and add it to the above solvent to dissolve completely to form the alcohol phase.

[0032] Weigh Tween 60 and citrate buffer solution into the prescribed amount of water to dissolve completely and make the water phase.

[0033] Keep the temperature at 50-60°C, and slowly add the water phase to the alcohol phase.

[0034] Keep the temperature at 50°C, stir for 30 minutes, stop heating, and continue stirring to about 40°C.

[0035] Filling, sealing, capping.

[0036] Fill the propellant.

[0037] Citrate buffer preparation method: take 10% potassium citrate solution and use 10% citric acid solution to adjust the pH value to 7.0.

Embodiment 2

10

[0041] Weigh absolute ethanol and propylene glycol and mix them uniformly as a solvent, keep the temperature at 40°C, and set aside.

[0042] Add octadecyl alcohol, stir at 60°C to dissolve completely, keep the temperature at 40°C, and set aside.

[0043] Weigh ketoconazole and add it to the above solvent to dissolve completely to form the alcohol phase.

[0044] Weigh Tween 60 and citrate buffer solution into the prescribed amount of water to dissolve completely and make the water phase.

[0045] Keeping the temperature at 40°C, the water phase was slowly added to the alcohol phase.

[0046] Keep the temperature at 40°C and stir for 1 hour.

[0047] Filling, sealing, capping.

[0048] Fill the propellant.

[0049] Citrate buffer preparation method: with embodiment 1.

[0050]The state of the sample prepared by the method of Example 2 is not significantly different from that of the sample prepared in Example 1.

Embodiment 3

[0053] Weigh absolute ethanol and propylene glycol and mix them uniformly as a solvent, keep the temperature at 40°C, and set aside.

[0054] Add octadecyl alcohol, stir at 60°C to dissolve completely, keep the temperature at 40°C, and set aside.

[0055] Weigh ketoconazole and add it to the above solvent to dissolve completely to form the alcohol phase.

[0056] Weigh Tween 60 and citrate buffer solution into the prescribed amount of water to dissolve completely and make the water phase.

[0057] Keeping the temperature at 40°C, the water phase was slowly added to the alcohol phase.

[0058] Keep the temperature at 40°C and stir for 1 hour.

[0059] Filling, sealing, capping.

[0060] Fill the propellant.

[0061] Citrate buffer preparation method: with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com