Method and apparatus for resin transfer molding composite parts

A technology for resin transfer molding, molding equipment, applied in textiles and papermaking, textiles, fabrics, etc., which can solve the problems of not considering controlled cooling, limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

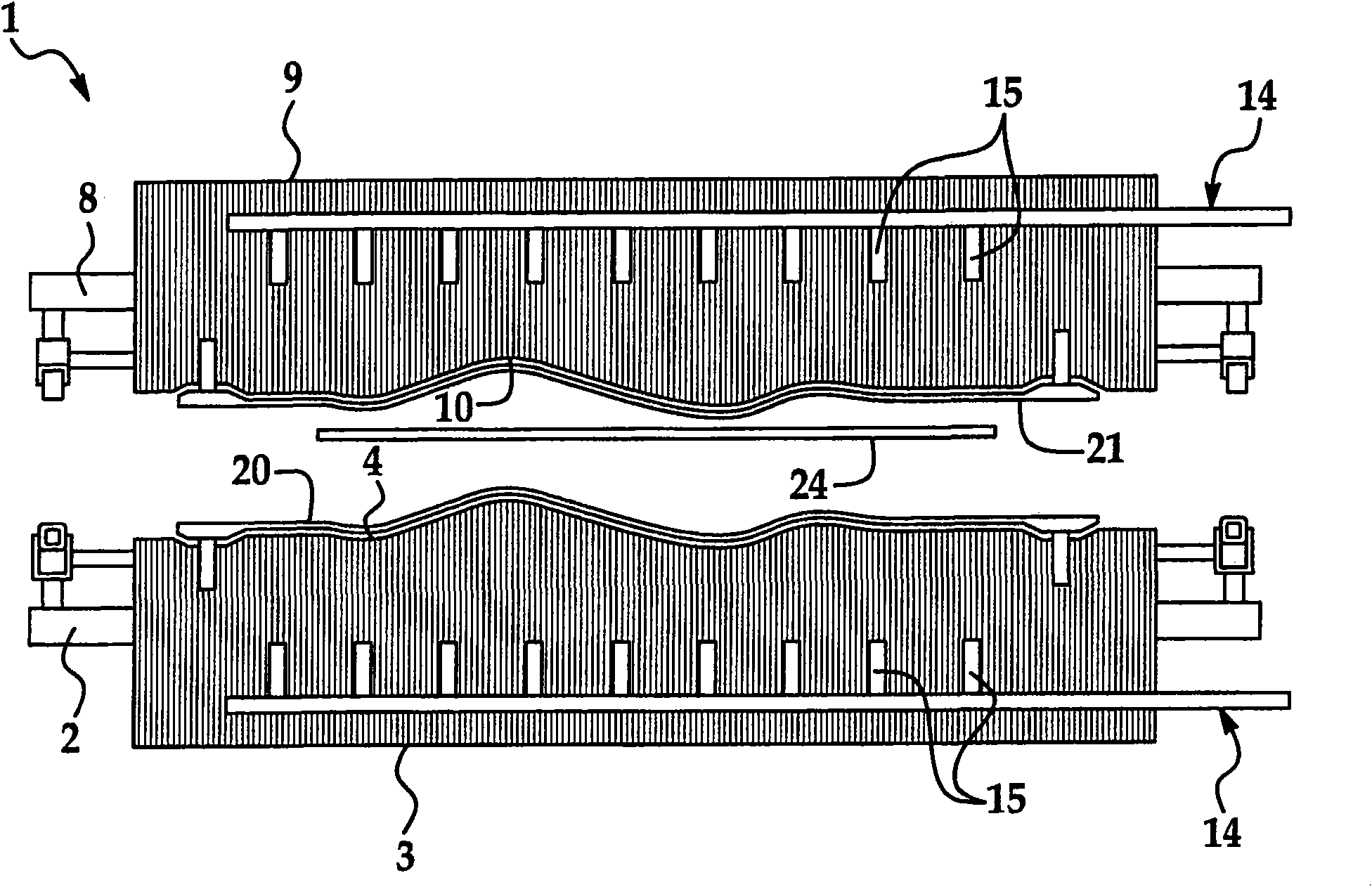

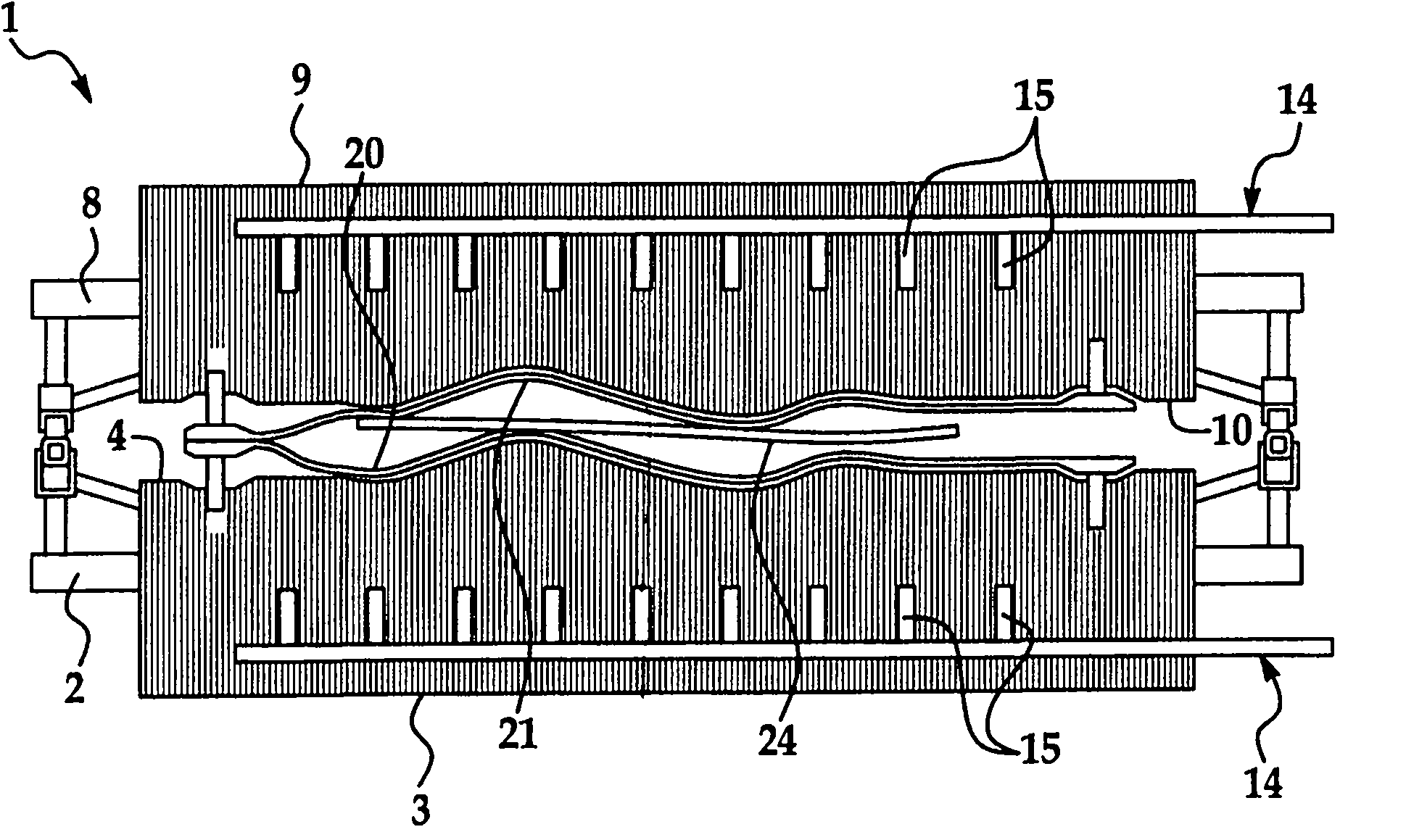

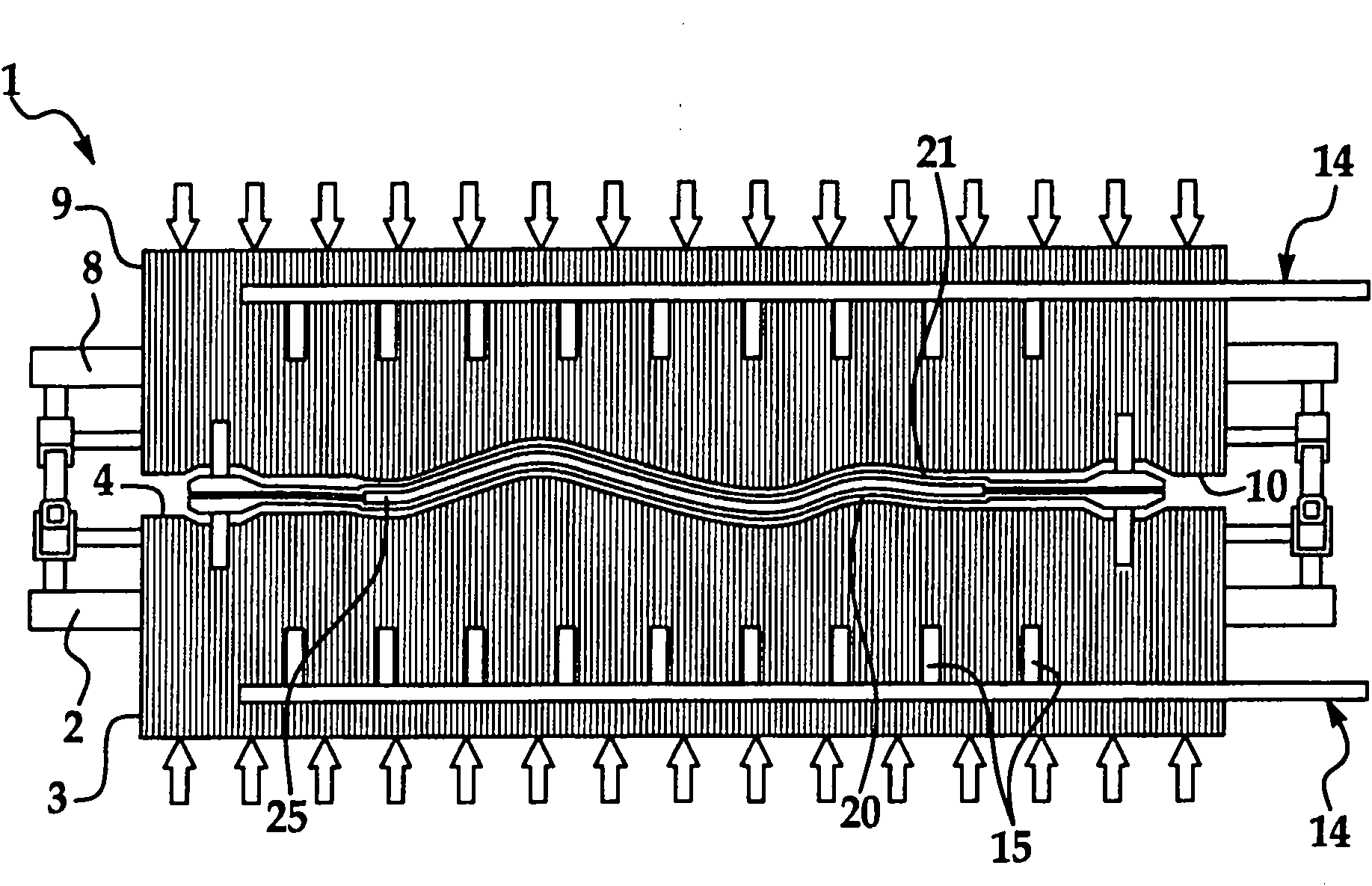

[0024] refer to the previous Figure 1-7 , generally denoted by the reference number 1 a stacked tooling device suitable for implementing a composite manufacturing method. The stacked tooling device 1 comprises a first mold frame 2 and a second mold frame 8 . The first tooling mold 3 may be arranged on the first mold frame 2 and the second tooling mold 9 may be arranged on the second mold frame 8 . The first tooling 3 and the second tooling 9 may be hydraulically actuated to facilitate movement of the first tooling 3 and the second tooling 9 towards and away from each other. The first tooling die 3 may have a first forming die surface 4 and the second tooling die 9 may have a second forming die surface 10 complementary to the first forming die surface 4 of the first tooling die 3 .

[0025] Such as Figure 6 As shown, a plurality of induction coils 26 may extend through each first tooling 3 (and second tooling 9 , not shown) to facilitate selective heating of the first tool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com