Air intake-exhaust integrated machine

An integrated, exhaust tube technology, applied in the exhaust device, fuel air filter, combustion air/combustion-air treatment, etc., can solve the problem that the waste heat of the exhaust tube is not well utilized, and the combustion of the oil and gas mixture is incomplete. , toxic and harmful exhaust emissions, etc., to achieve the effect of improving efficiency, sufficient fuel, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

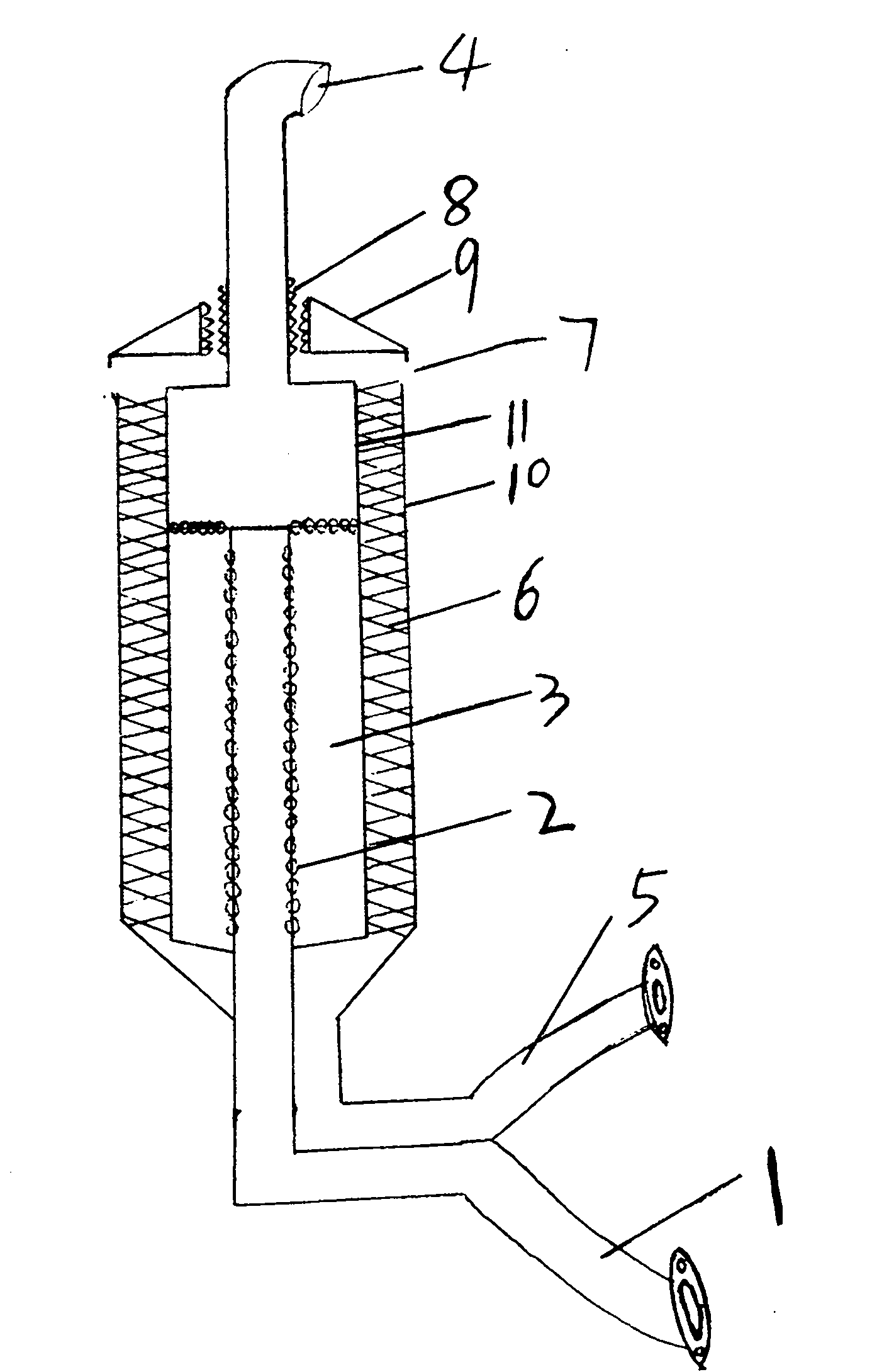

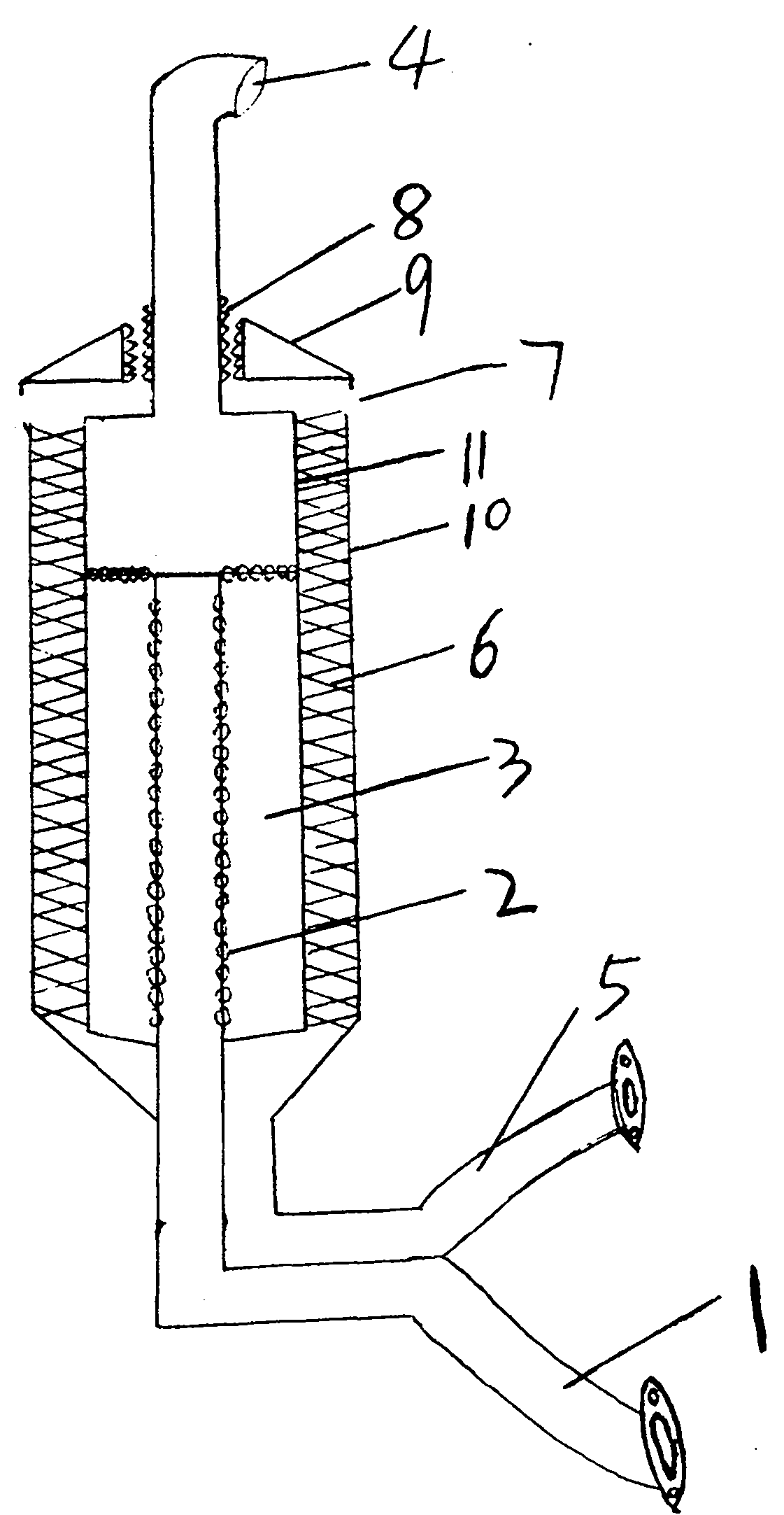

[0010] The present invention is further elaborated in conjunction with the accompanying drawings of the description.

[0011] The invention consists of an exhaust tube 1, a muffler hole 2, an exhaust tube 3 and an exhaust port 4, an exhaust tube wall 11, an air inlet 7, a steel wire filter screen 6, an air filter tube 10, an air intake pipe 5, and an exhaust tube. Mouth 4, lower end exhaust pipe have turnbuckle pipe 8 and pipe 5, turnbuckle 8 and nut air filter cover 9 to form. The wire filter screen can be taken out from the nut filter pipe 9 where the turnbuckle 5 is unscrewed for cleaning. When the burned gas enters through the exhaust pipe 1, it enters the exhaust cylinder 3 through the muffler hole 2, and the incoming air is filtered and cleaned by the steel wire filter 6, and is fully contacted with the exhaust cylinder wall 11 for preheating. The air enters the cylinder from the intake pipe, and after being compressed by the cylinder piston, super-high-temperature gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com