Interdigitated rotor engine

A rotary engine and engine technology, applied to combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of increased sealing and processing difficulty, long flame propagation path, and reduced power of the whole machine, so as to achieve easy production and maintenance, Effects of weight and volume reduction and torque curve uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

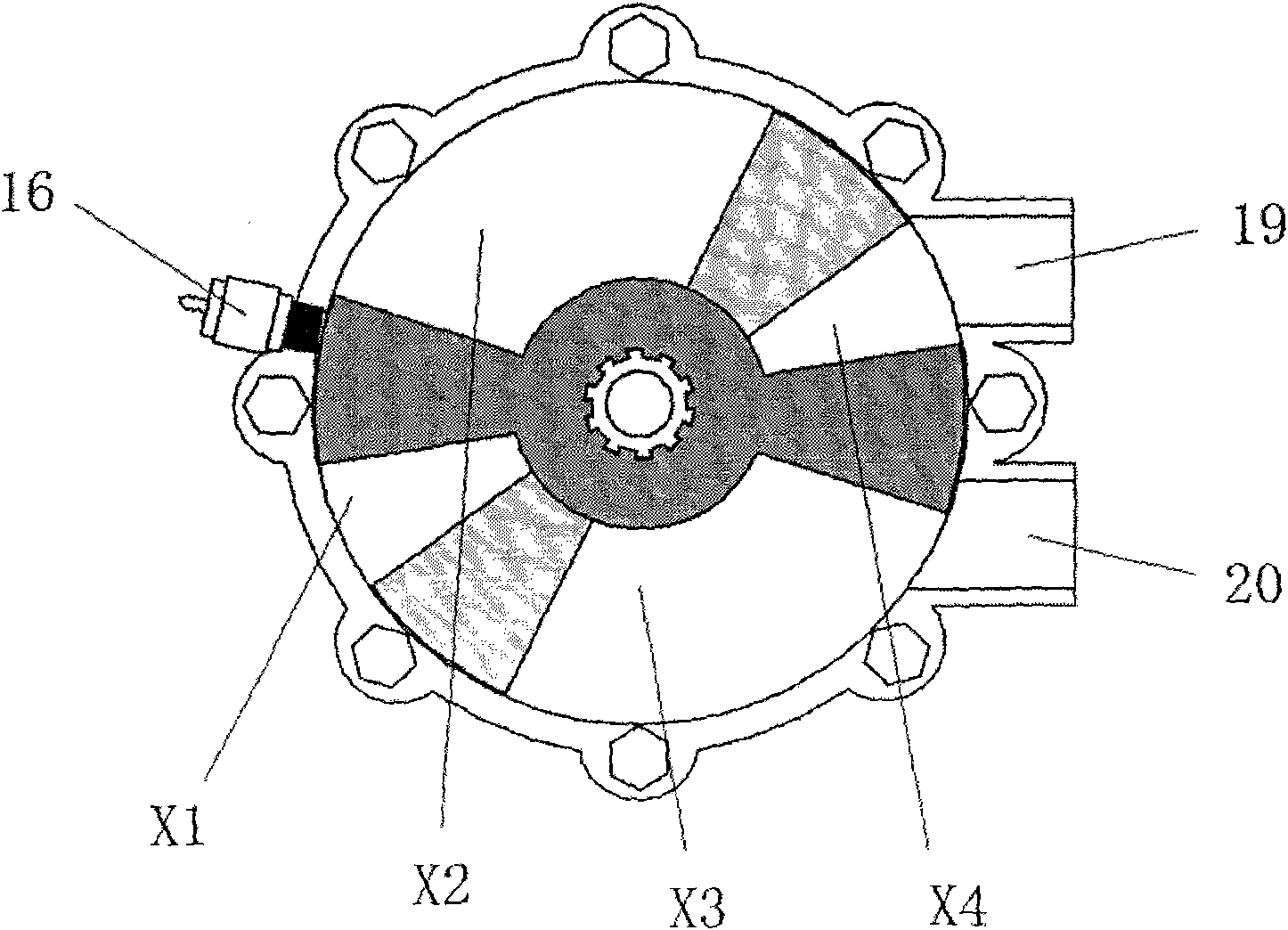

[0034] 1. Various parts of the engine

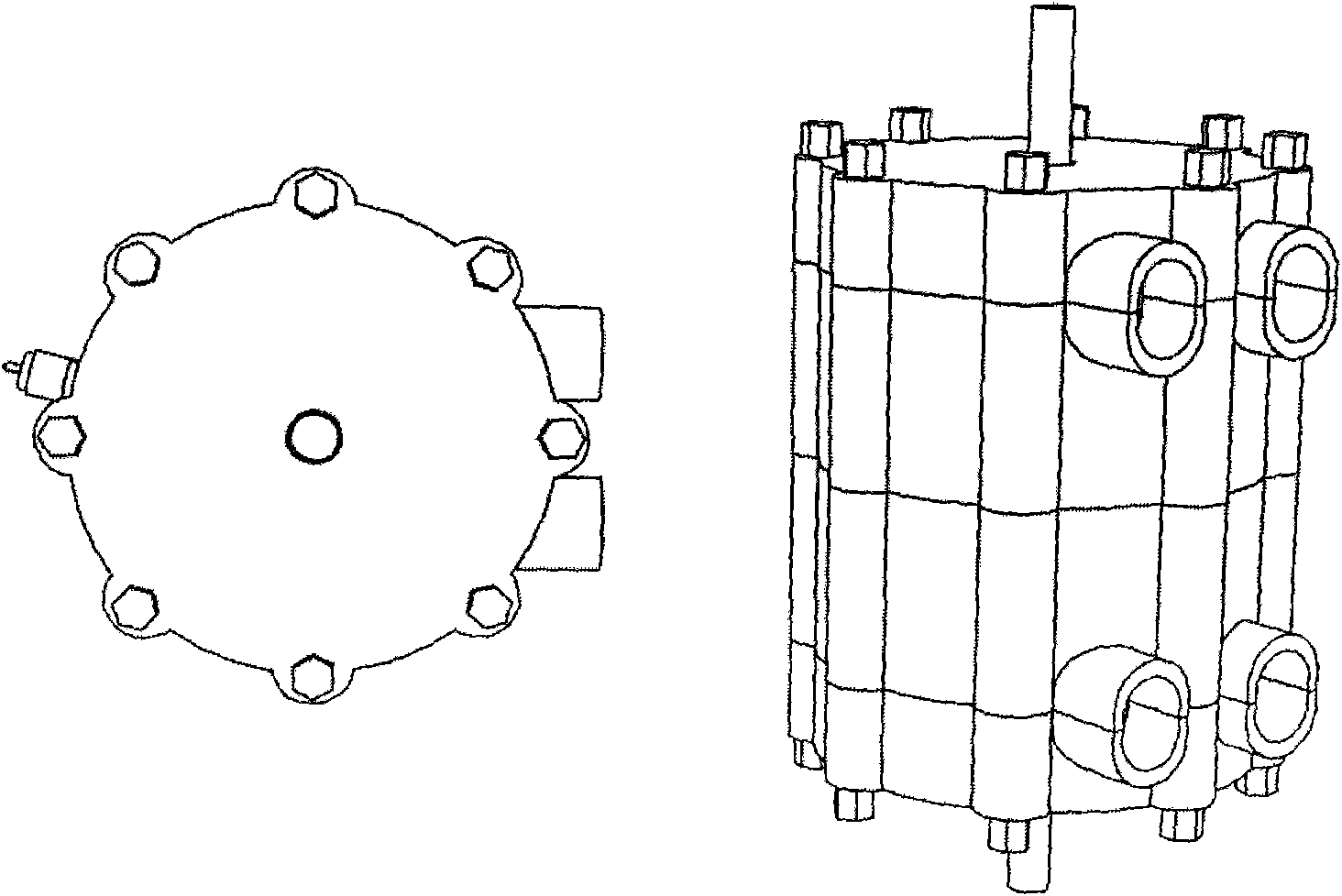

[0035] Such as figure 1 Shown is a schematic diagram of the appearance of the engine. It can be understood from the figure that the shape of the engine of the present invention is a cylinder, and the output shaft of the engine protrudes from the upper and lower top surfaces of the cylinder for connecting load equipment. There are two sets of upper and lower gas ports on one side of the cylinder, and each set of gas ports is provided with an air inlet and an exhaust port. On the other side of the cylinder at the position corresponding to the gas port, a plurality of spark plugs are arranged, and their positions are closer to one end of the exhaust port for shortening the time of ignition timing.

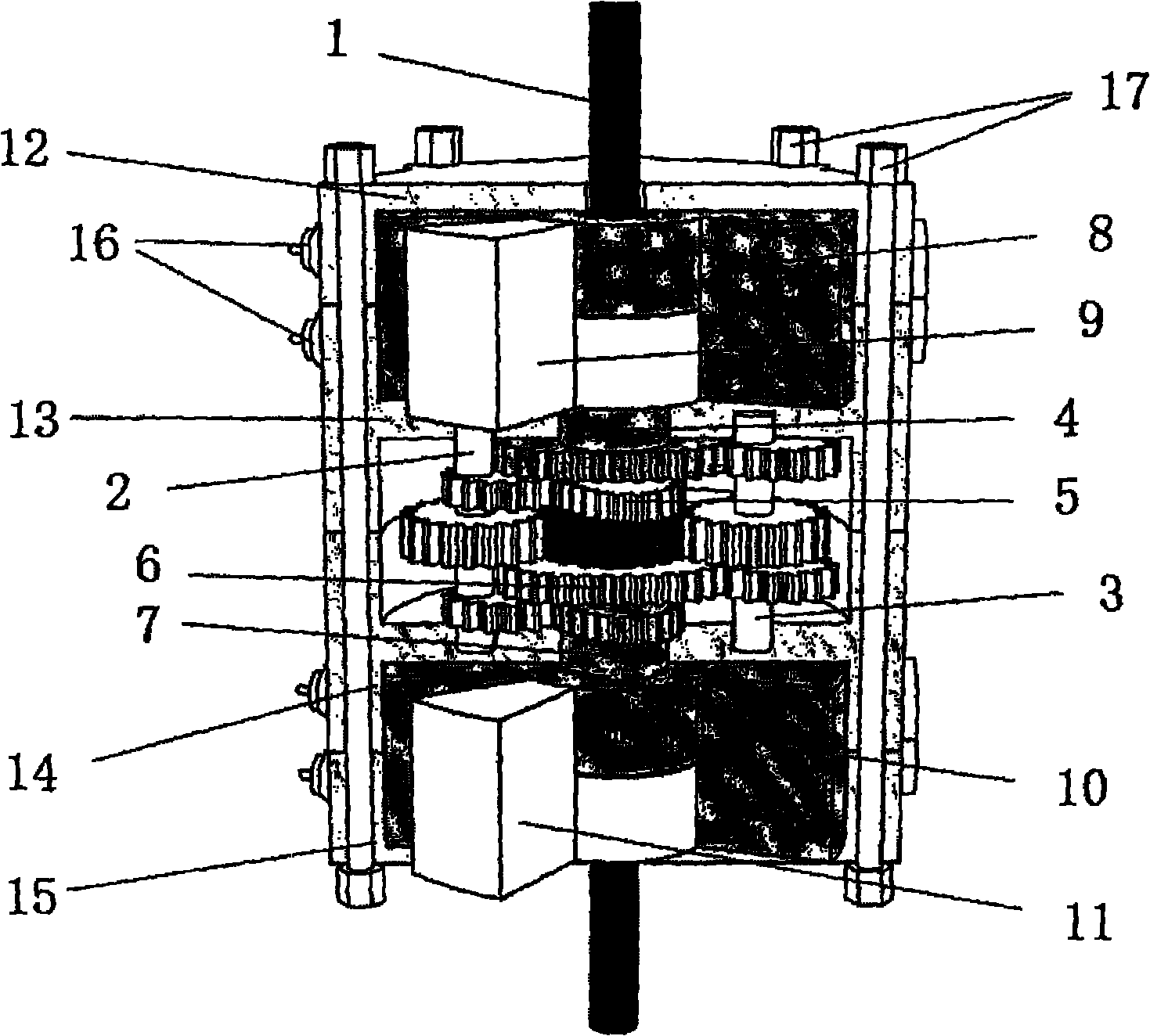

[0036] Such as figure 2 The schematic diagram of the longitudinal section of the engine is shown in the figure. All the important components of the whole machine are marked in the figure, and their positions and functions are intuitively disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com