Convenient rapid supporting loading and unloading mechanism and supporting loading and unloading method

A steel support and flange technology, applied in excavation, infrastructure engineering, construction, etc., can solve the problems of support failure, inability to dismantle, and many construction processes, and achieve the effect of improving construction efficiency, shortening construction time, and safe and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Now in conjunction with accompanying drawing and embodiment the invention is described in further detail.

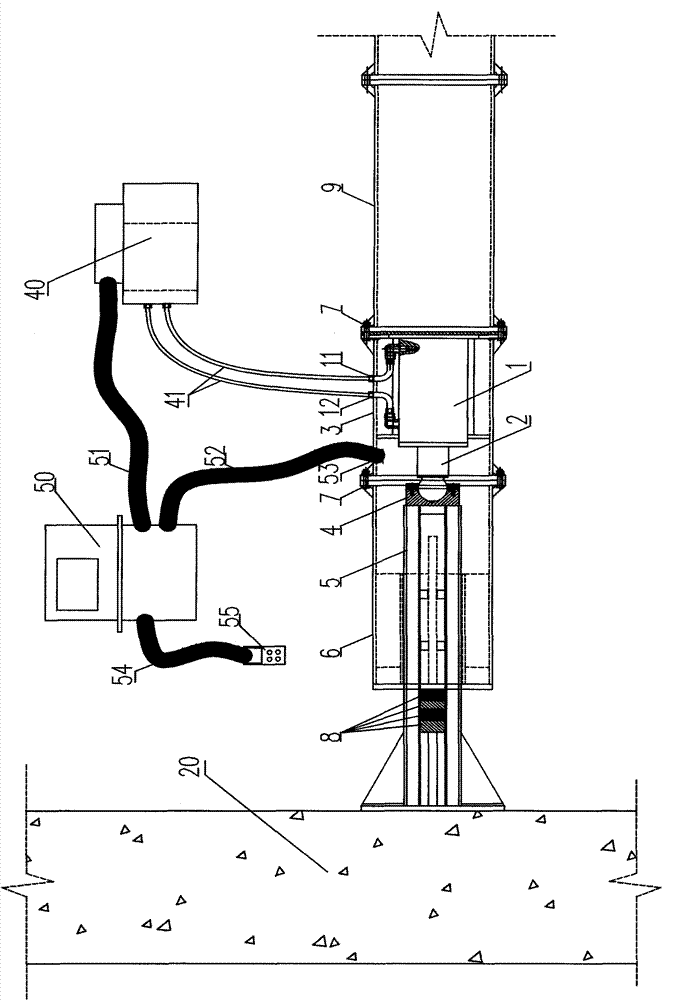

[0039] see figure 1 and figure 2 . The traditional steel support consists of a steel support end structure 6 , a support active joint 5 and a standard section support 9 .

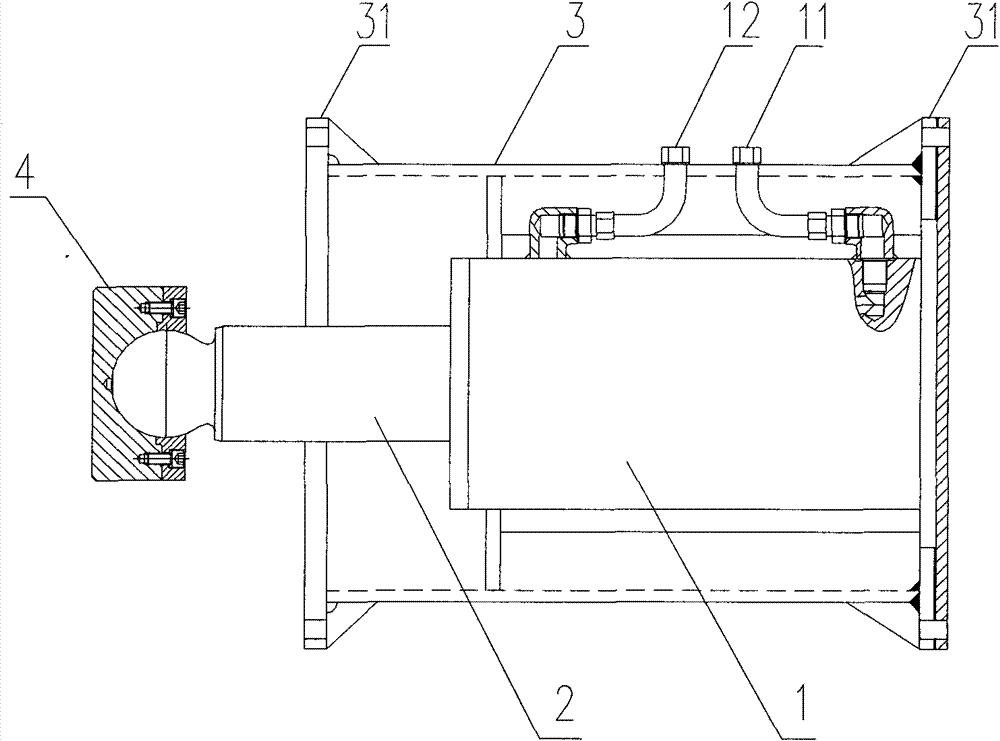

[0040] The supporting loading and unloading mechanism of the present invention includes: a hydraulic cylinder 1, a cylinder piston rod 2, a steel support sleeve 3, the hydraulic cylinder 1 is provided with an oil inlet pipe port 11 and an oil return pipe port 12, and the steel support sleeve 3 is provided with a front end steel method The flange 31 and the rear-end steel flange 32, the front-end steel flange 31 and the rear-end steel flange 32 are respectively provided with connecting holes 311, 321 and the like.

[0041]The hydraulic cylinder 1 with built-in travel sensor and pressure sensor (not shown in the figure) is installed and fixed in the steel support sleeve 3, and the oil inlet p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com