Composite sleeper

A technology for sleepers and composite materials, which is applied in the field of sleepers composed of polymer composite materials, can solve the problems of overall failure of sleepers, single longitudinal arrangement of glass fibers, and shear damage between layers, and achieves good noise absorption, high safety, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

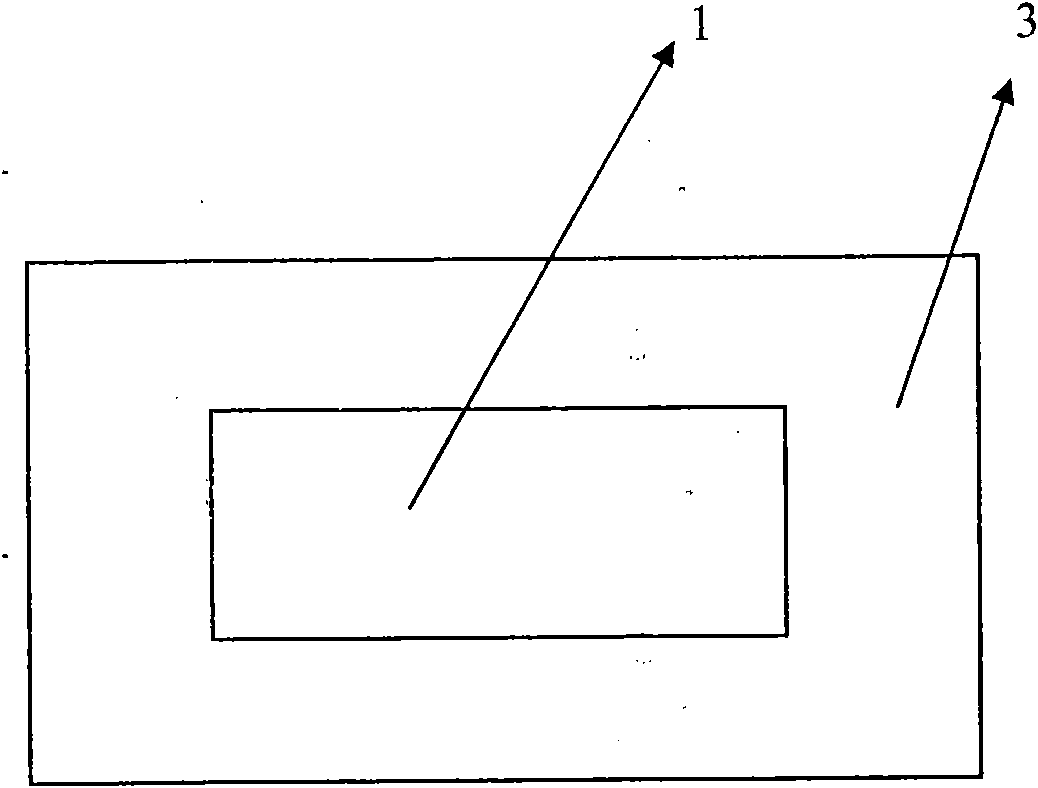

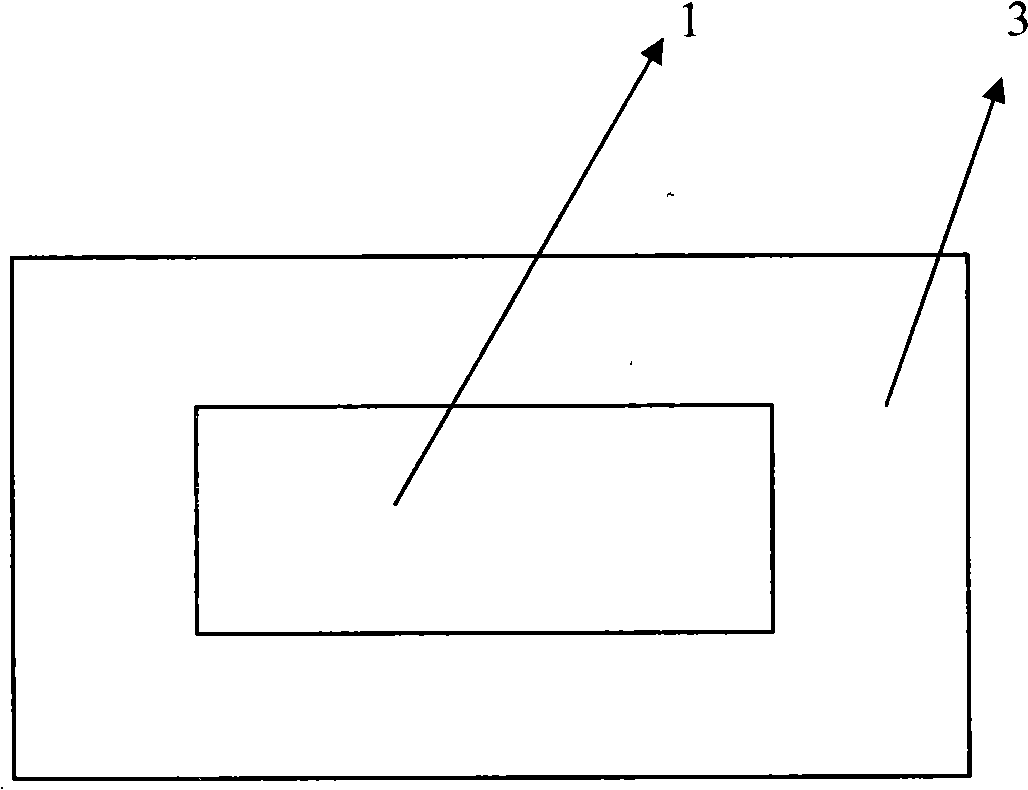

[0033] figure 1 It is a schematic cross-sectional view of the composite sleeper according to the present invention. In this figure, it can be seen that the composite sleeper is divided into two layers, wherein the innermost inner core 1 is a composite material, and the outer layer 3 is treated with a coupling agent surface. Glass fiber multi-axial cloth impregnated with polyurethane resin.

[0034] First, select 30% by weight of trihydric alcohol, 69.9% by weight of isocyanate, and 0.1% by weight of foaming agent, and mix the above raw materials to prepare a polyurethane resin stock solution for use.

[0035] Select a commercially available glass fiber reinforced unsaturated polyester resin composite material as the material of the inner core 1, process it into specifications of 2000-3200 mm in length, 100-230 mm in width, and 100-290 mm in height, and then make the grammage 600 g / m 2 The alkali-free glass fiber triaxial cloth that has been surface-treated by a silane coupl...

Embodiment 2

[0038] Select 59.5% by weight of trihydric alcohol, 40.0% by weight of isocyanate, and 0.5% by weight of foaming agent, and mix the above raw materials to prepare a polyurethane resin stock solution for use. In addition, the unsaturated polyester resin is diluted with the dissolving agent styrene to obtain a solution of the unsaturated polyester resin for use.

[0039] Select the wood residue reinforced phenolic resin-based composite material as the material of the inner core 1, process it into specifications of 2000-3200mm in length, 100-230mm in width, and 100-290mm in height, and then make the grammage 900g / m 2 The alkali-free glass fiber triaxial cloth that has been surface-treated by a silane coupling agent is wrapped on the outside of the above-mentioned inner core 1, and the above-mentioned prepared polyurethane resin stock solution is sprayed on the alkali-free glass fiber triaxial cloth , so that the polyurethane resin stock solution infiltrates the alkali-free glass ...

Embodiment 3

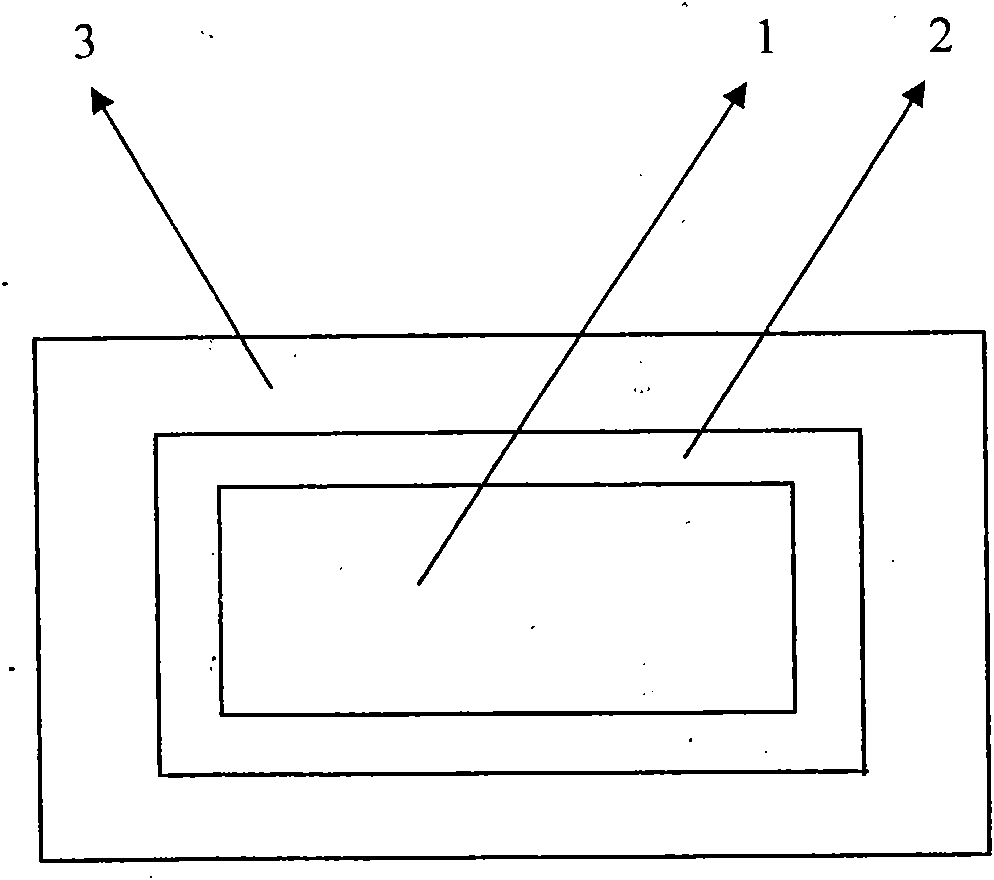

[0043] figure 2 It is a schematic sectional view of the structure of a composite sleeper further provided with a sandwich layer according to the present invention. In this figure, it can be seen that the composite sleeper is divided into three layers, wherein the innermost inner core 1 is a composite material, and the outer layer 3 is A glass fiber multi-axial cloth impregnated with a polyurethane resin after surface treatment with a coupling agent, and the sandwich layer 2 between the above two layers is a glass fiber roving impregnated with a polyurethane resin.

[0044] Select 29.9% by weight of trihydric alcohol, 70.0% by weight of isocyanate, and 0.1% by weight of foaming agent, and mix the above raw materials to obtain a polyurethane resin stock solution for use. In addition, the unsaturated polyester resin is diluted with the dissolving agent styrene to obtain a solution of the unsaturated polyester resin for use.

[0045] Select the rubber-plastic composite material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| linear density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| foaming ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com