Liquid crystal aligning agent and liquid crystal display device

A liquid crystal alignment agent and liquid crystal alignment technology, applied in liquid crystal materials, chemical instruments and methods, instruments, etc., can solve problems such as intensification, achieve high heat resistance and light resistance, excellent liquid crystal orientation, and excellent storage stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

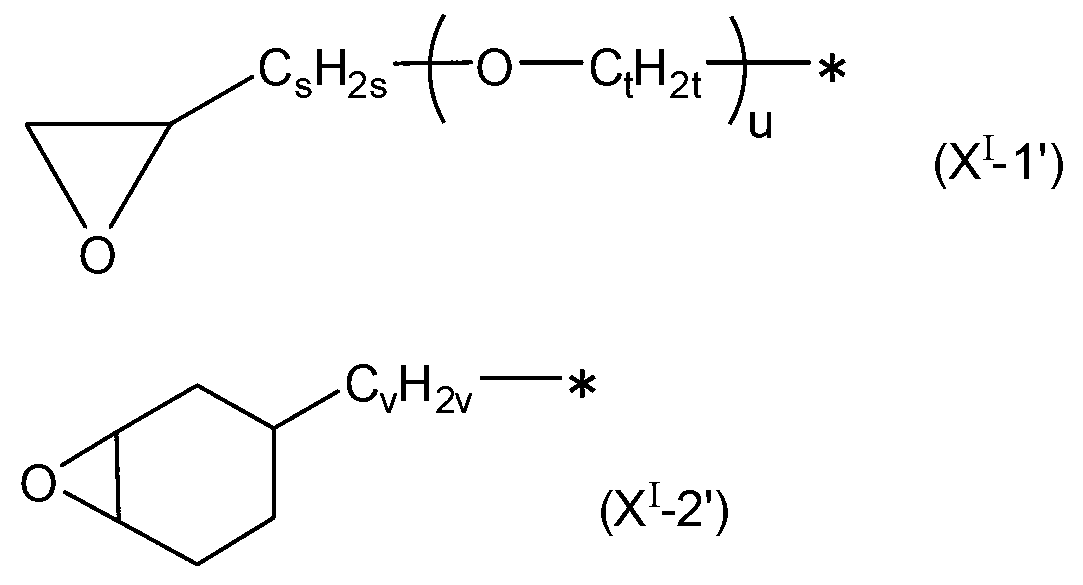

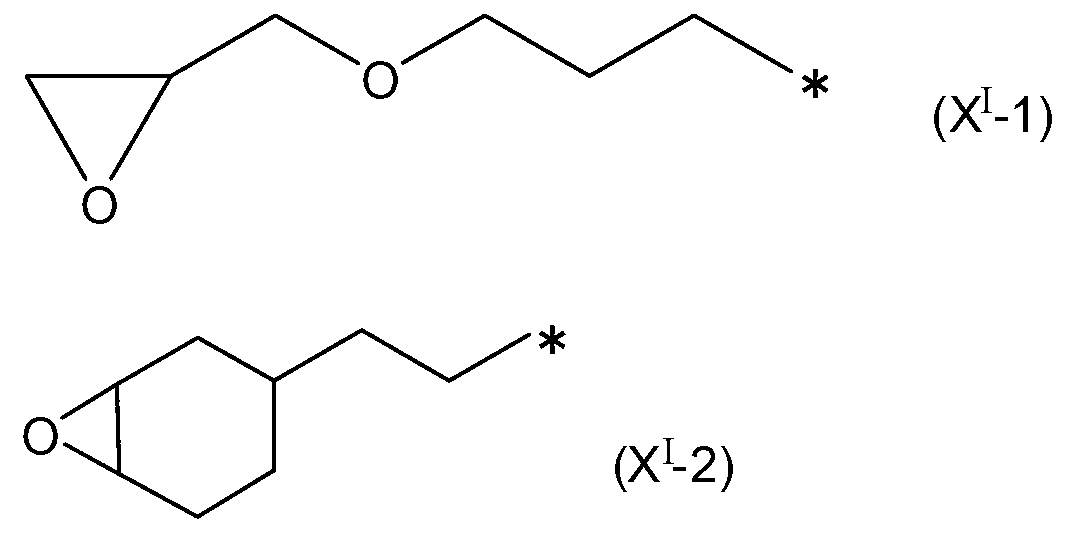

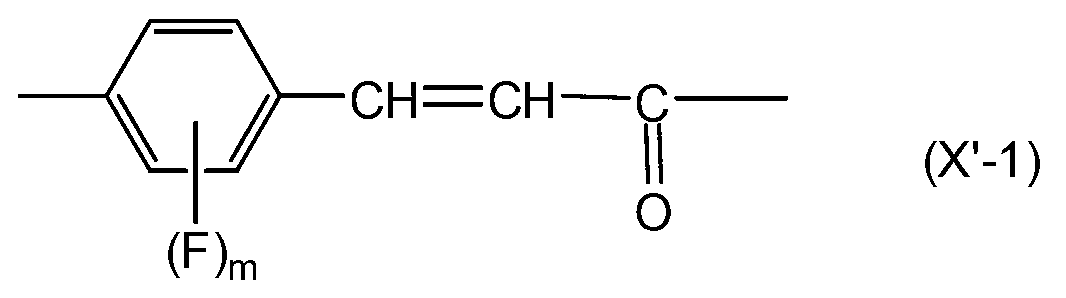

Method used

Image

Examples

Synthetic example 1

[0431] In a reaction vessel with a stirrer, thermometer, dropping funnel and reflux condenser, add 100.0 g of 2-(3,4-epoxycyclohexyl) ethyl trimethoxysilane, 500 g of methyl isobutyl ketone and 10.0 g of triethylamine, mixed at room temperature. Next, after adding 100 g of deionized water dropwise over 30 minutes from the dropping funnel, it was reacted at 80° C. for 6 hours while mixing under reflux. After the reaction, the organic layer was taken out, washed with 0.2% by weight of ammonium nitrate aqueous solution until the washed water was neutral, and the solvent and water were distilled off under reduced pressure to obtain polyorganosiloxane EPS-1, which was viscous Transparent liquid.

[0432] The polyorganosiloxane EPS-1 is carried out 1 In H-NMR analysis, a peak of theoretical intensity based on the oxosilyl group was obtained around chemical shift (δ) = 3.2 ppm, and it was confirmed that no side reaction occurred in the epoxy group during the reaction.

[0433] The...

Synthetic example VE-1

[0484] Into a 200 mL three-necked flask, 10.0 g of the polyorganosiloxane EPS-1 synthesized in Synthesis Example 1 and 30.28 g of methyl isobutyl ketone were added. 3.82 g of stearic acid (corresponding to 50 mol% with respect to the epoxy group that polyorganosiloxane EPS-1 has) and 0.10 g of UCAT 18X (trade name, manufactured by Sunapro (KK), is the curing agent of epoxy compound Accelerator), stirred at 100°C for 48 hours to react. After the reaction, methanol was added to the reaction mixture to form a precipitate, which was dissolved in ethyl acetate, and the resulting solution was washed three times with water. After the organic layer was dried with magnesium sulfate, the solvent was distilled off to obtain 8.1 g polyorganosiloxane White powder of S-VE-1. The weight average molecular weight of S-VE-1 was 10,100.

Synthetic example VE-2

[0486] In the above Synthesis Example VE-1, except that 3.98 g of 4-n-dodecyloxybenzoic acid was used instead of stearic acid, 9.0 g of polyorganosiloxane S- White powder of VE-2. The weight average molecular weight of S-VE-2 was 9,900.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com