Ball milling method for preparing organic vermiculite with large layer distance

A technology of interlayer spacing and ball milling, applied in inorganic chemistry, chemical instruments and methods, non-metallic elements, etc., can solve problems such as unfavorable macromolecular chain insertion, large interlayer force between inorganic sheets, and large interlayer charge density. , to achieve the effect of improving the internal structure, complete morphology, and large interlayer spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

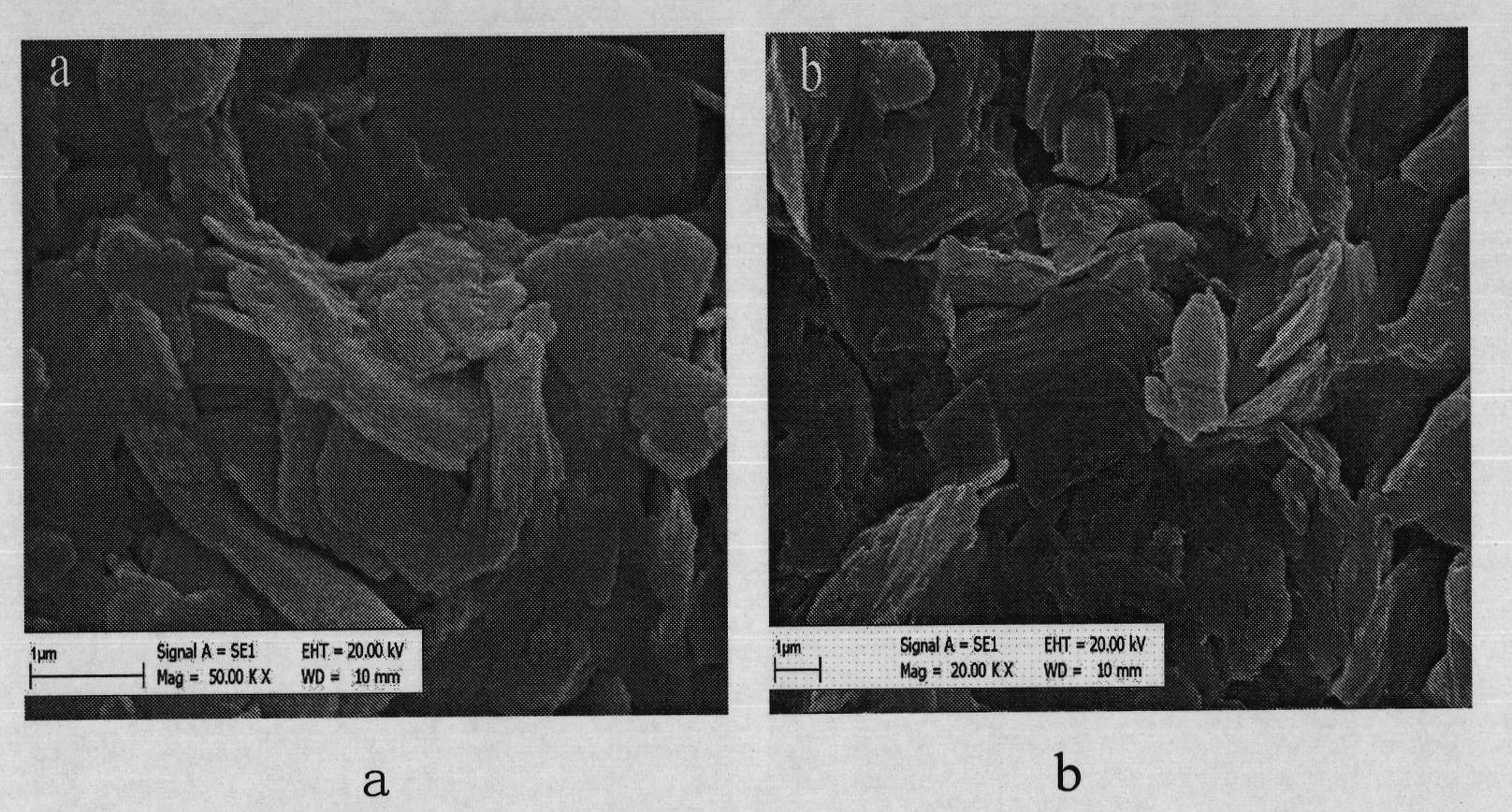

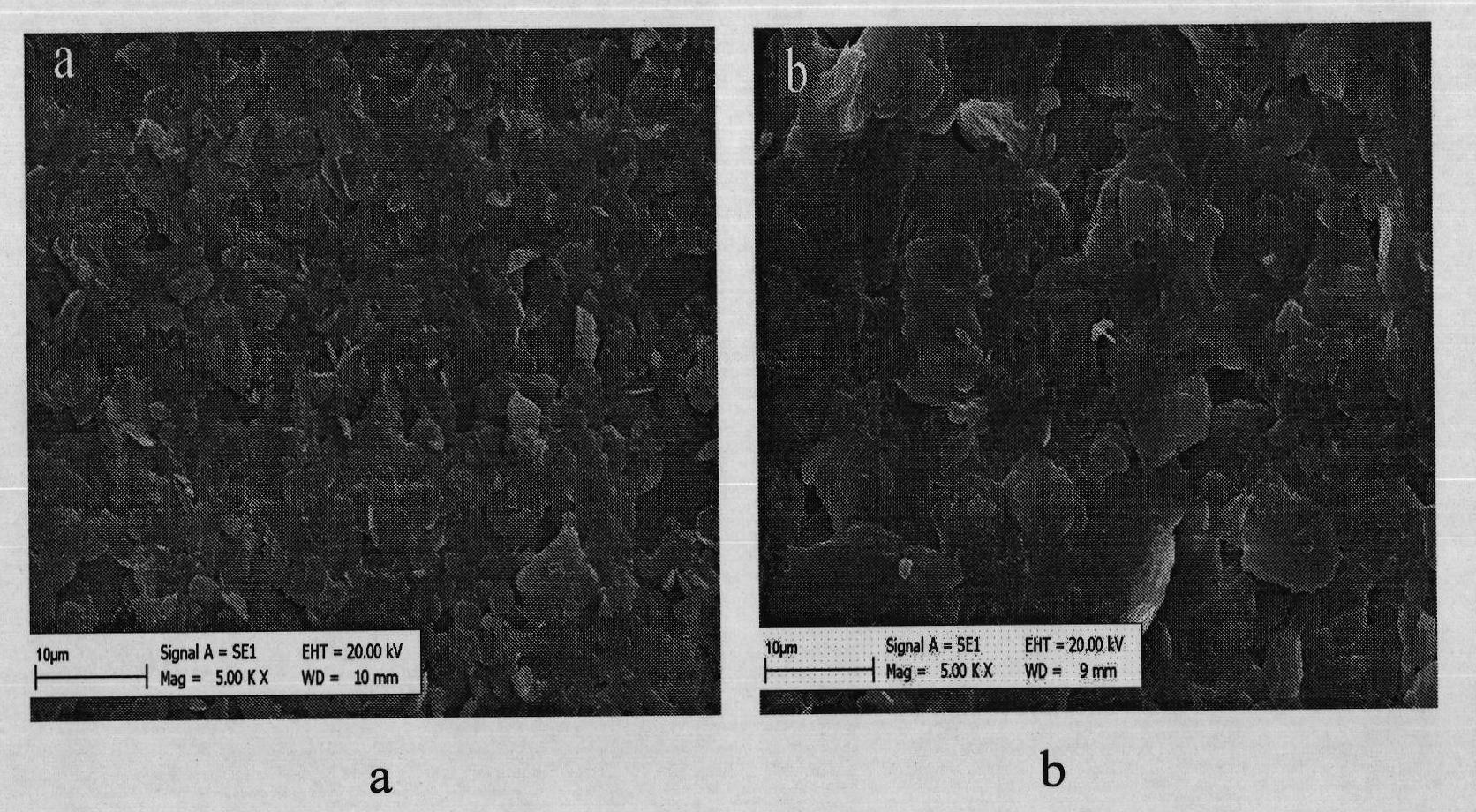

Image

Examples

Embodiment 1

[0033] a, Xinjiang Yuli vermiculite was cleaned with deionized water and dried for 48 hours;

[0034] B, vermiculite is pulverized with universal pulverizer, crosses 325 mesh sieves, obtains powder;

[0035]c. Prepare a solution containing 1.0 mol / L of sodium chloride and 0.25 mol / L of hydrochloric acid, and disperse the vermiculite powder in step b in the solution by stirring to form a slurry containing 15% vermiculite mass fraction, and then ultrasonically disperse, The reaction temperature is 50°C, and the reaction time is 48 hours;

[0036] d. After the reaction is over, wash with deionized water and vacuum filter until the solution is deionized with 0.1mol / L AgNO 3 Detect that there is no Cl in the filtrate - Until it exists, a solid sample is obtained;

[0037] e. Dry the solid sample at a temperature of 70° C. in a blast drying oven for 24 hours, grind and pass through a 200-mesh sieve to obtain sodium vermiculite with a cation exchange capacity of 92.55 mmol / 100 g; ...

Embodiment 2

[0041] a, Xinjiang Yuli vermiculite was cleaned with deionized water and dried for 48 hours;

[0042] B, vermiculite is pulverized with universal pulverizer, crosses 325 mesh sieves, obtains powder;

[0043] c. Prepare a solution containing 1.0 mol / L of sodium chloride and 0.25 mol / L of hydrochloric acid, and disperse the vermiculite powder in step b in the solution by stirring to form a slurry containing 15% vermiculite mass fraction, and then ultrasonically disperse, The reaction temperature is 60°C, and the reaction time is 36 hours;

[0044] d. After the reaction is over, wash with deionized water and vacuum filter until the solution is deionized with 0.1mol / L AgNO 3 Detect that there is no Cl in the filtrate - Until it exists, a solid sample is obtained;

[0045] e. Dry the solid sample at a temperature of 70°C in a blast drying oven for 24 hours, grind it, and pass it through a 200-mesh sieve to obtain sodium vermiculite with a cation exchange capacity of 96.25mm / 100g...

Embodiment 3

[0049] a, Xinjiang Yuli vermiculite was cleaned with deionized water and dried for 48 hours;

[0050] B, vermiculite is pulverized with universal pulverizer, crosses 325 mesh sieves, obtains powder;

[0051] c. Prepare a solution containing 1.0 mol / L of sodium chloride and 0.25 mol / L of hydrochloric acid, and disperse the vermiculite powder in step b in the solution by stirring to form a slurry containing 15% vermiculite mass fraction, and then ultrasonically disperse, The reaction temperature is 70°C, and the reaction time is 24 hours;

[0052] d. After the reaction is over, wash with deionized water and vacuum filter until the solution is deionized with 0.1mol / L AgNO 3 Detect that there is no Cl in the filtrate - Until it exists, a solid sample is obtained;

[0053] e. Dry the solid sample at a temperature of 70°C in a blast drying oven for 24 hours, grind it, and pass through a 200-mesh sieve to obtain sodium vermiculite with a cation exchange capacity of 94.38mm / 100g; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com