Rolling bearing having internal lubrication

A kind of rolling bearing and bearing technology, which is applied in the field of rolling bearing of rolling parts, can solve the problem of not allowing the lubrication of rolling parts in an effective and economical way.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

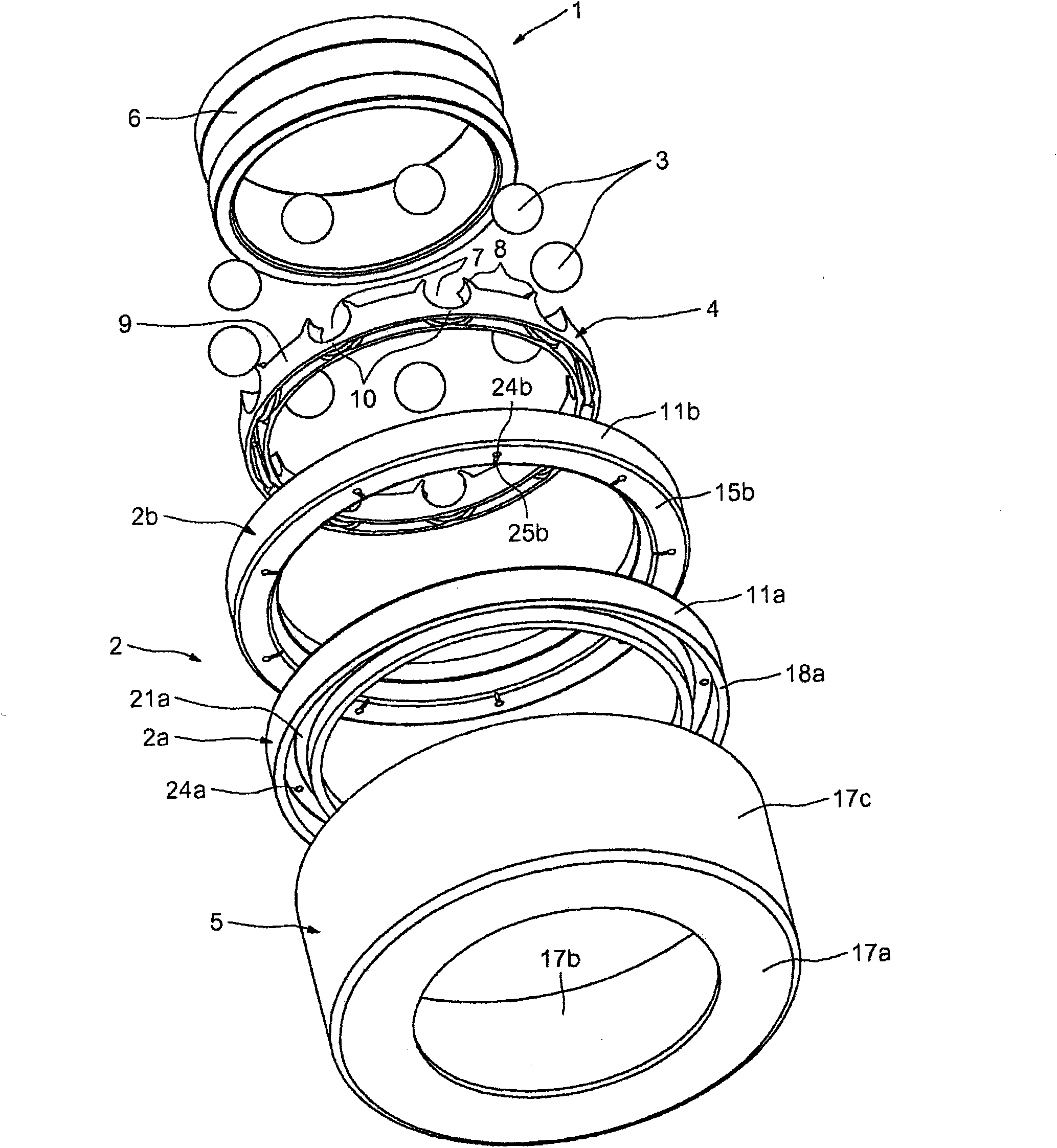

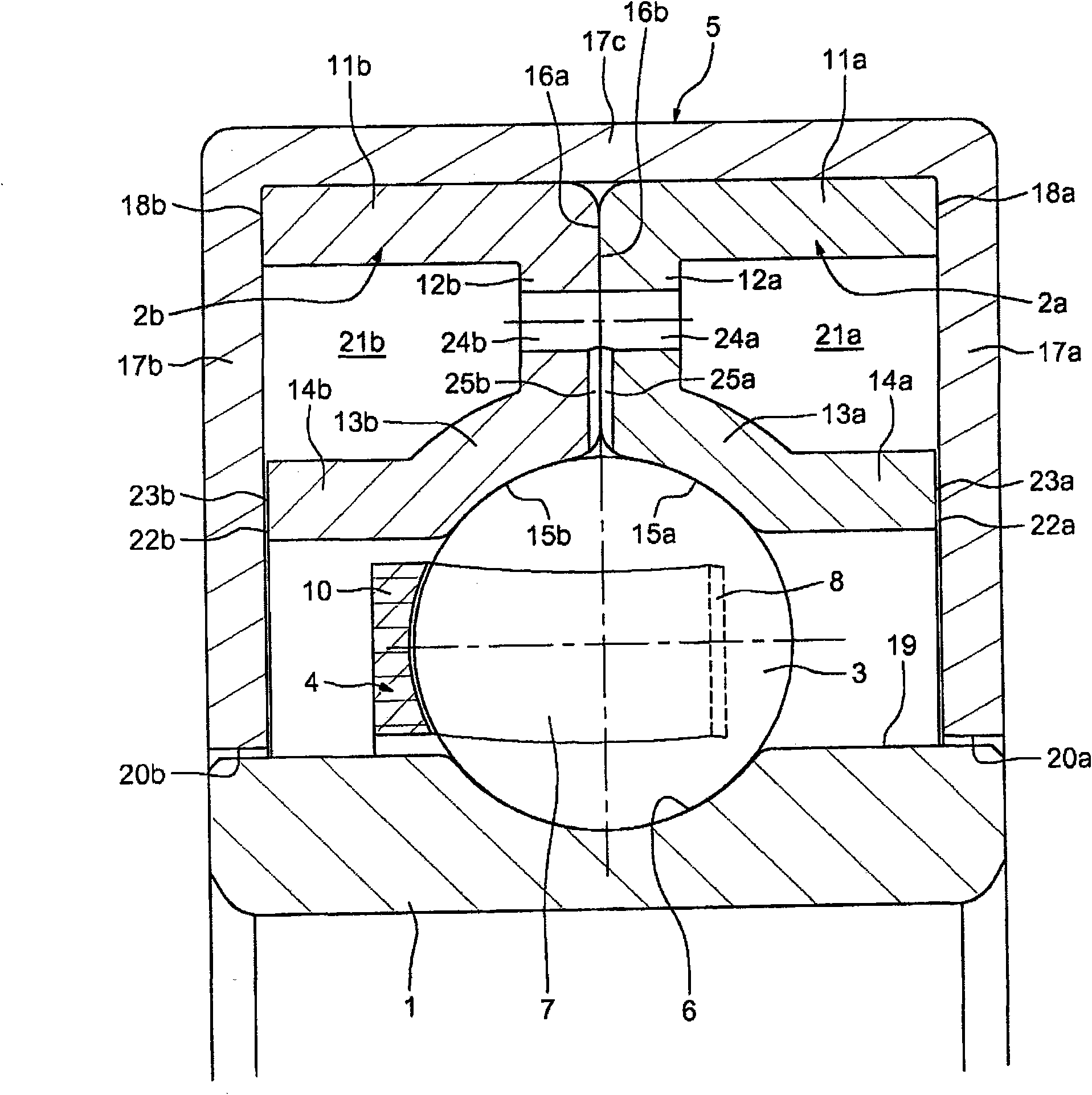

[0038] First refer to figure 1 and 2 , which shows a first embodiment of a rolling bearing according to the invention, said bearing having an inner ring 1 and an outer ring 2 and a row of rolling parts, said outer ring consisting of two outer half rings 2a, 2b, said rolling The components consist in the example shown of balls 3 held between inner ring 1 and outer ring 2 by cage 4 . An annular housing 5 surrounds the two outer half-rings 2a, 2b.

[0039] In this example, the inner ring 1 is designed to be mounted in a rotating part. In this way, the inner ring 1 constitutes the rotating ring of the bearing, while the outer ring 2 constitutes the non-rotating ring. The inner ring 1 is solid and has an annular groove 6 with a radius of curvature slightly greater than that of the balls 3 and forming a bearing raceway for the balls 3 . The inner ring 1 can be given its geometry and its final surface finish by turning or by forming a billet, then grinding and optionally polishin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com