Waste pipe branching

A waste and branching technology, applied in the direction of vertical pipelines, conveying bulk materials, solid waste removal, etc., can solve the problems affecting the vacuum volume, the increase in the demand for the overall vacuum volume, and the weakening of the air velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

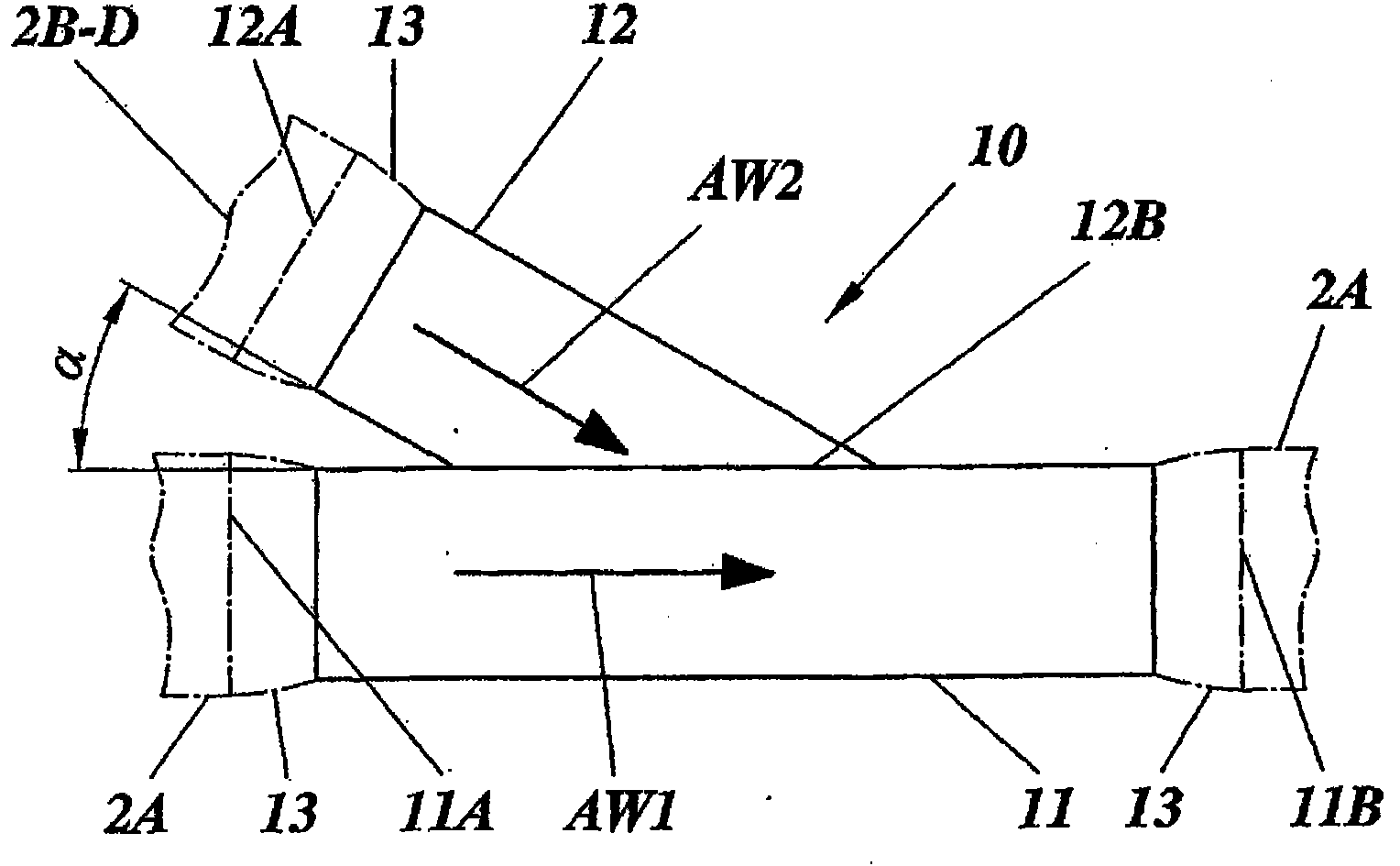

[0030] The following is a combination of the paradigm of the embodiment and the application of the innovative branch connector to illustrate the present invention. The illustration of the branch connector is visible Figure 2-15B . The first embodiment of the branch connector of the present invention can be seen Figure 2-8 ; This embodiment is about an innovative solution, applied to a partial and schematic waste transportation pipeline; the waste transportation pipeline is provided with branches, used to segment the waste transportation pipeline of the vacuum-operated waste transportation system. The second and third embodiments of the branch connector of the present invention can be seen respectively Picture 9 and Figure 10-13 ; The two embodiments are about an innovative solution, applied to a partial and general description of the waste transportation pipeline; the waste transportation pipeline has branches, used to connect the waste collection warehouse and / or waste coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com