Installation method of big gear ring of rotary kiln

An installation method and technology of a large ring gear, applied in the field of installation of a large ring gear of a rotary kiln, can solve the problems of consumption of manpower and material resources, difficult to ensure the alignment accuracy of the large ring gear, unstable operation of the rotary kiln body, etc., so as to shorten the construction period. The effect of shortening the construction period and improving the installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

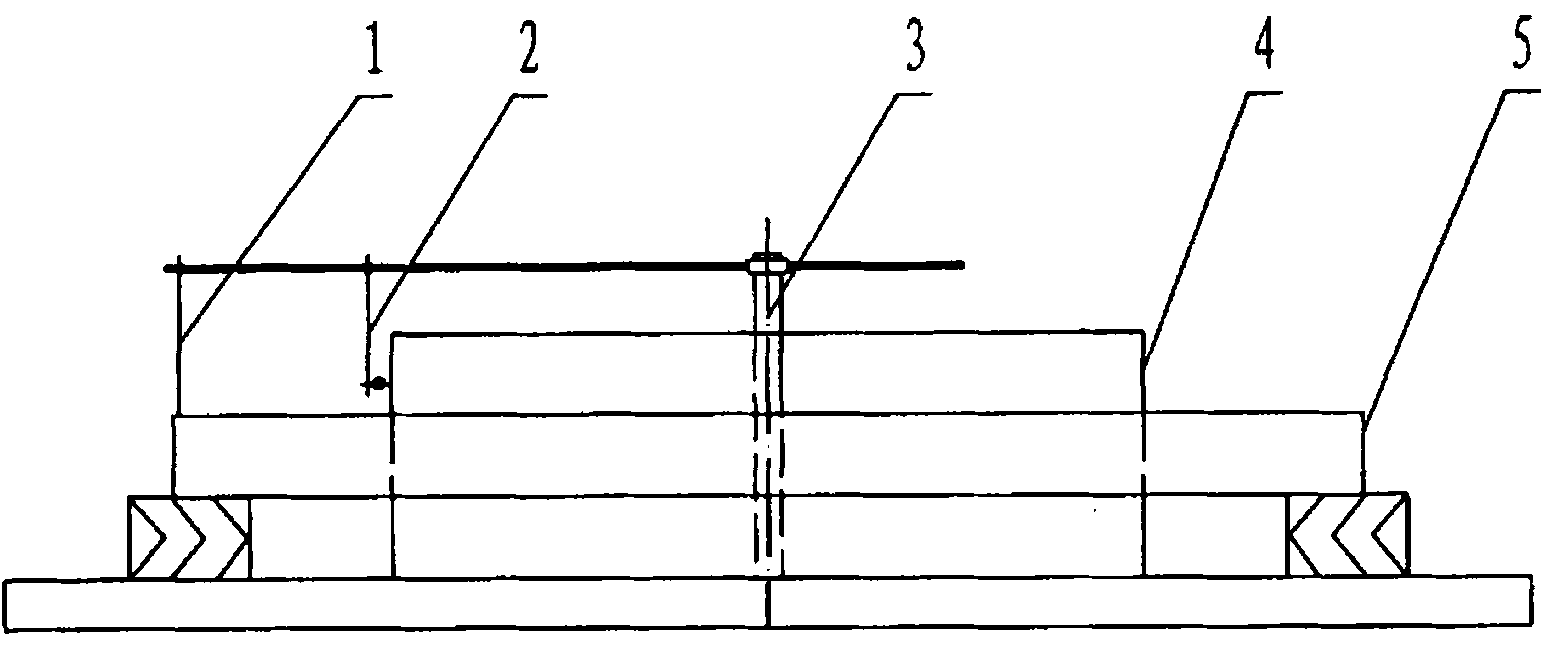

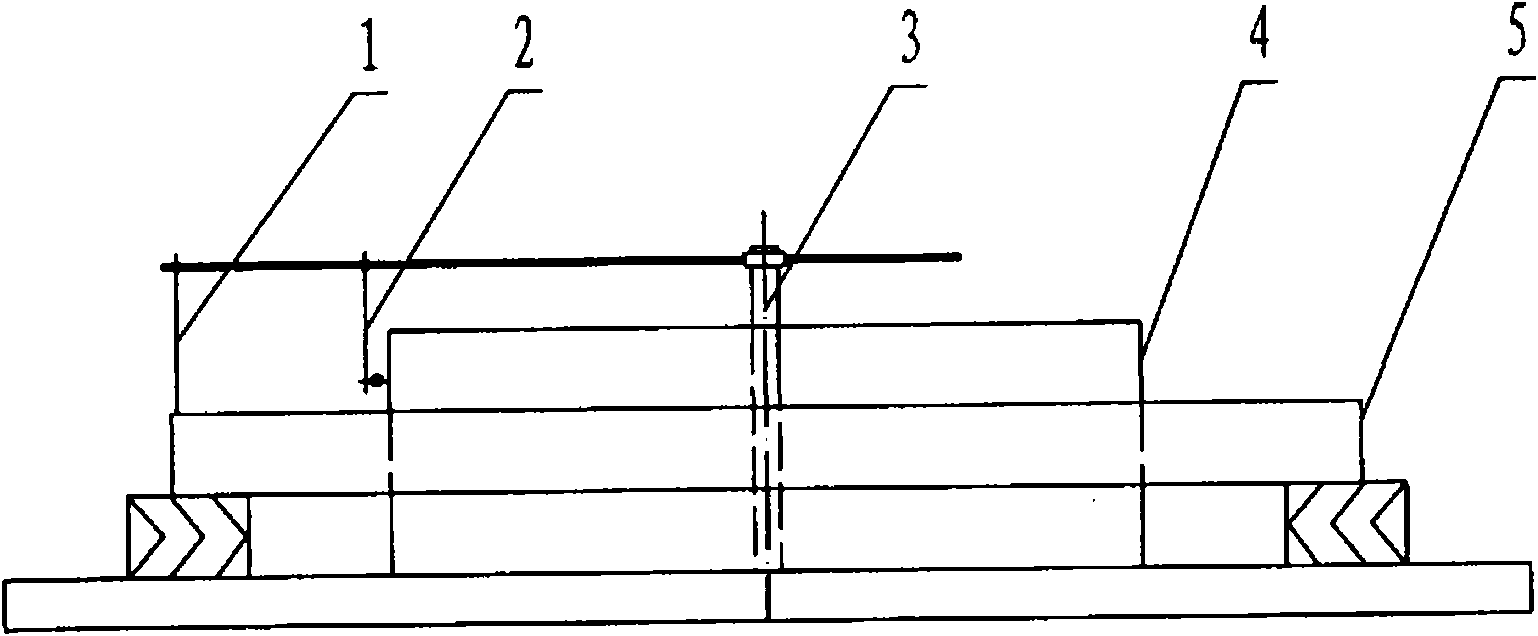

[0026] The large gear ring of the rotary kiln usually adopts two half-ring structures, which are connected together with matching screws and fixed tangentially on the kiln body through spring plates; the specific implementation steps are as follows:

[0027] 1. Set up a square assembly platform, the side length is 2m longer than the diameter of the large gear ring.

[0028] 2. The production of the connecting cylinder section of the large ring gear must be processed by a machine tool, and its roundness must meet the requirements, and the two ends of the cylinder section are vertical. And use the processing machine tool to draw the center line and the upper and lower two circumferential lines of the spring plate installation position on the outer circle.

[0029] 3. Large ring gear assembly and calibration

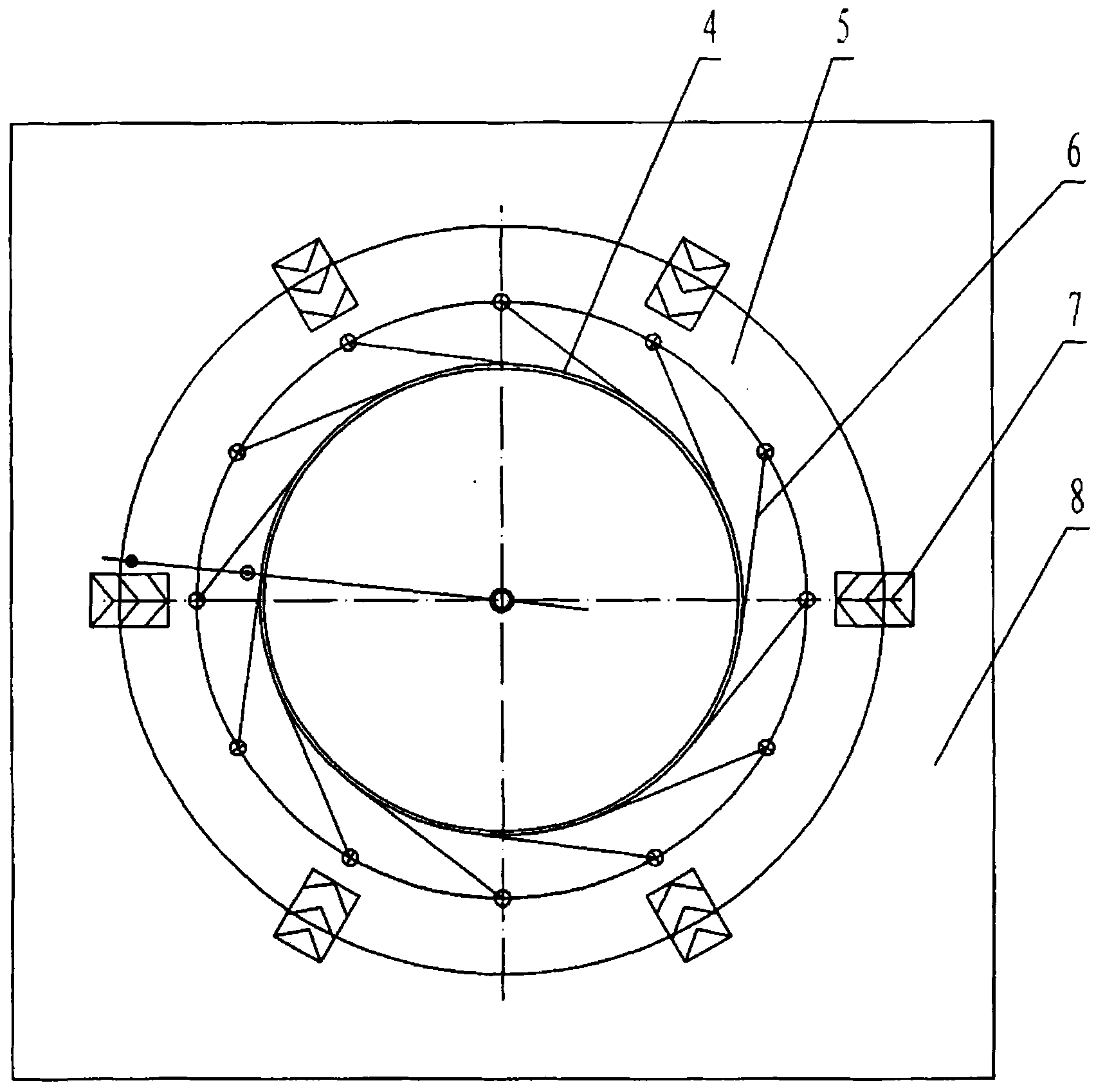

[0030] 3.1 Take the center of the platform as the center of the circle, plan the outer circle of the cylinder and the inner and outer circles of the end of the large ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com