Method of extraction and grading purification of ganoderma lucidum spore oil by supercritical CO2

A Ganoderma lucidum spore oil, fractional purification technology, applied in the direction of fat oil/fat production, fat production, etc., can solve the problems of reducing yield, solvent residue, increasing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

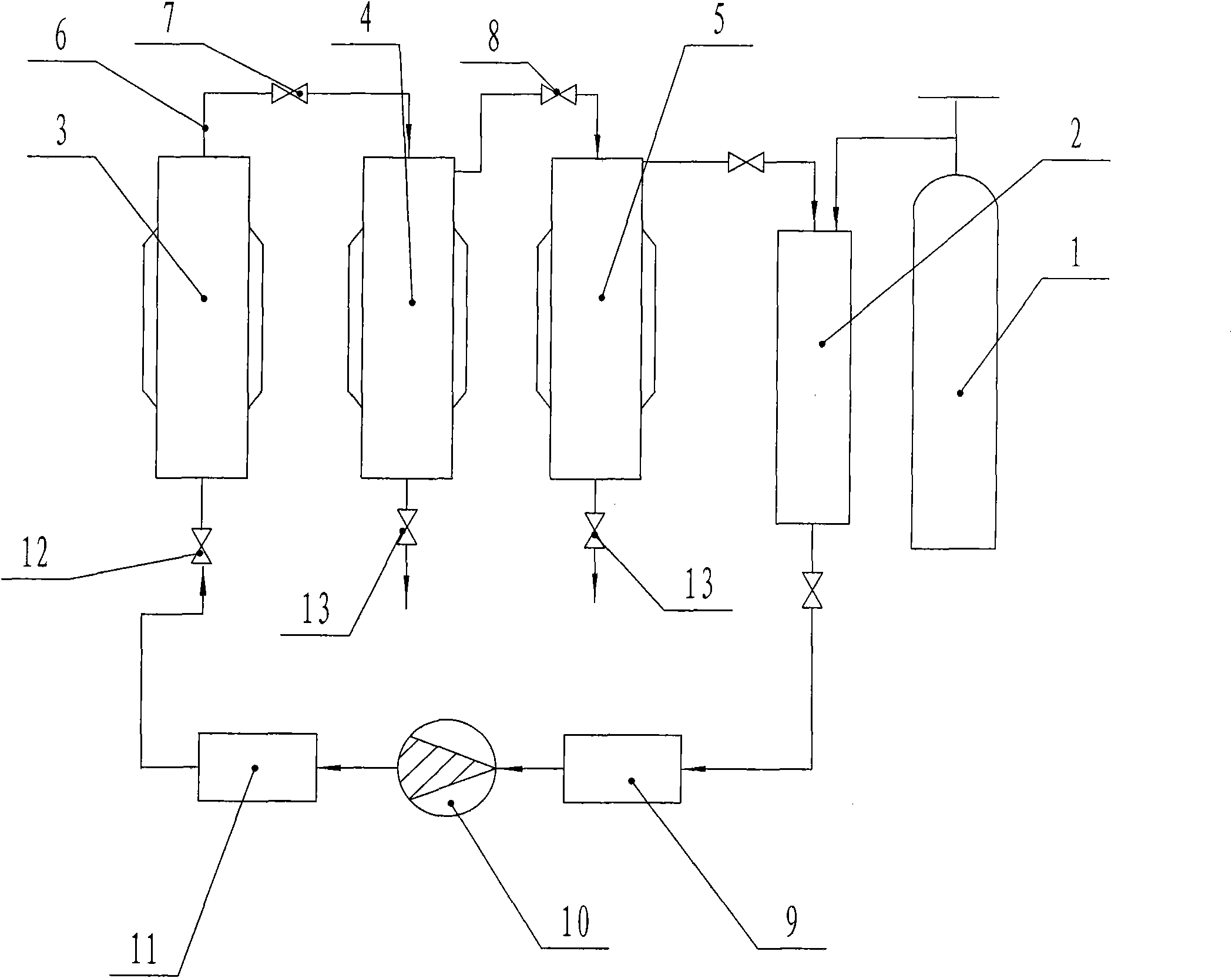

[0016] The equipment that the present invention adopts is a kind of supercritical CO 2 Equipment for extraction and fractional purification of Ganoderma lucidum spore oil, which is mainly composed of CO 2 Cylinder 1, CO 2 The storage tank 2, the extraction kettle 3, the primary separation kettle 4, and the secondary separation kettle 5 are connected in sequence, and are connected to each other by pipelines. CO 2 Available by CO 2 Cylinder 1 to CO 2 The storage tank 2 enters the extraction kettle through the heat exchanger I 9, the high-pressure pump 10, and the heat exchanger II 11, then enters the first-stage separation kettle 4 through the valve 7, and then enters the second-level separation kettle 5 through the valve 8. Back to CO 2 The storage tank 2 completes a working cycle, and there is a valve 12 under the extraction kettle for controlling CO 2 The lower part of the primary separation tank is the collection valve 13, and the lower part of the secondary separation ...

Embodiment 2

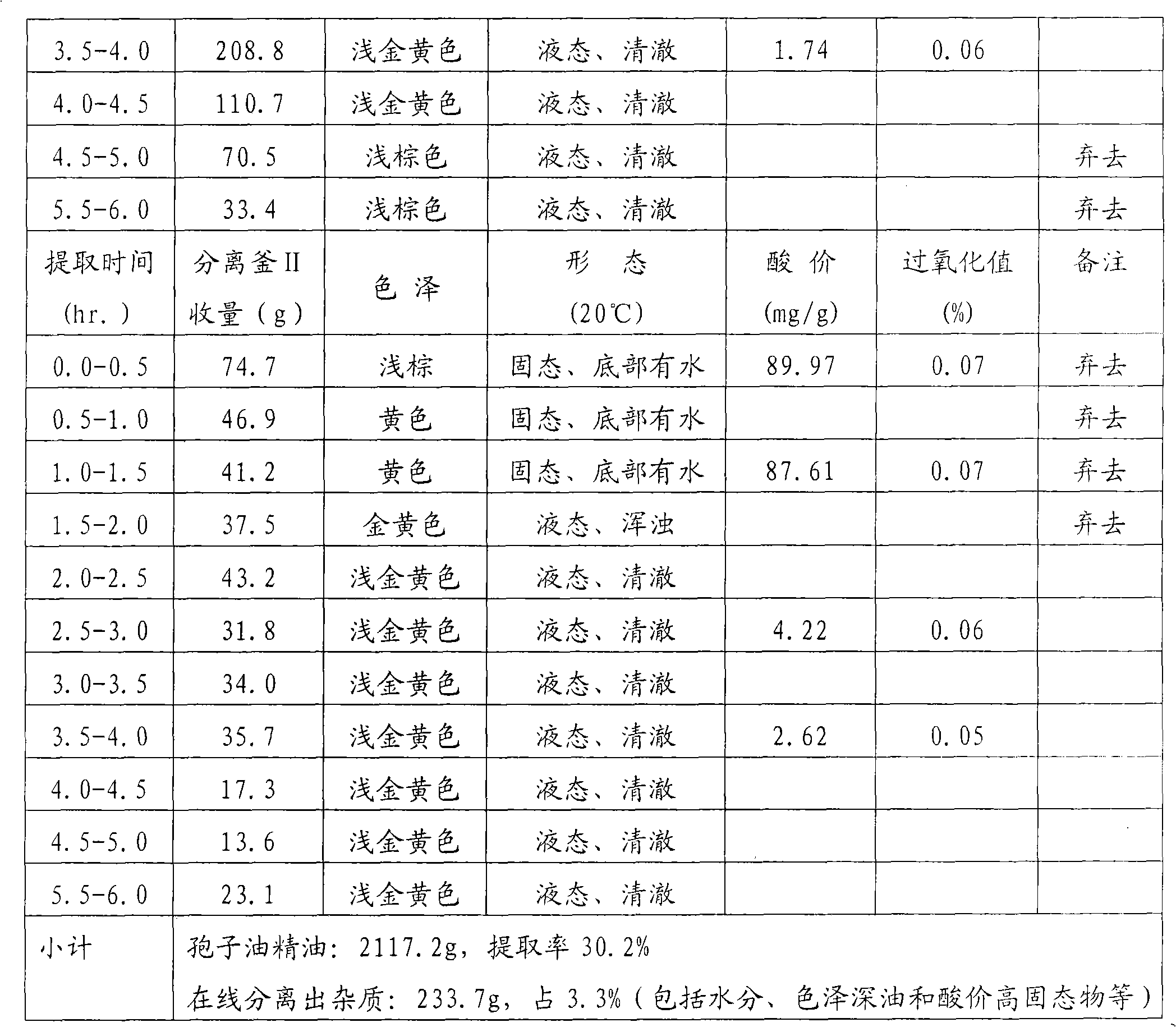

[0022] Broken Ganoderma lucidum spore powder 7.00kg, 24L extraction kettle pressure 25MPa temperature 45℃, separation kettle I pressure 10MPa, temperature 40℃, separation kettle II pressure 6MPa temperature 45℃, CO 2 The flow rate is 130L / hr. Other unmentioned parts are the same as the above example.

[0023] Table 2 Supercritical CO 2 Example 2 of collecting Ganoderma lucidum spore oil in stages by extracting and grading depressurization

[0024]

[0025]

[0026] Fatty acid analysis in the Ganoderma lucidum spore oil that the present invention extracts by experiment:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com