Preparation method of red fluorescent powder for LED (light-emitting diode)

A technology of red phosphor and white, applied in the field of preparation of red phosphor for LED, can solve the problems of high cost, complicated tungstate equipment and high color temperature, achieve the opportunity to reduce impurities, and is suitable for mass production and preparation process mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method of red fluorescent powder for LED, comprising the steps of:

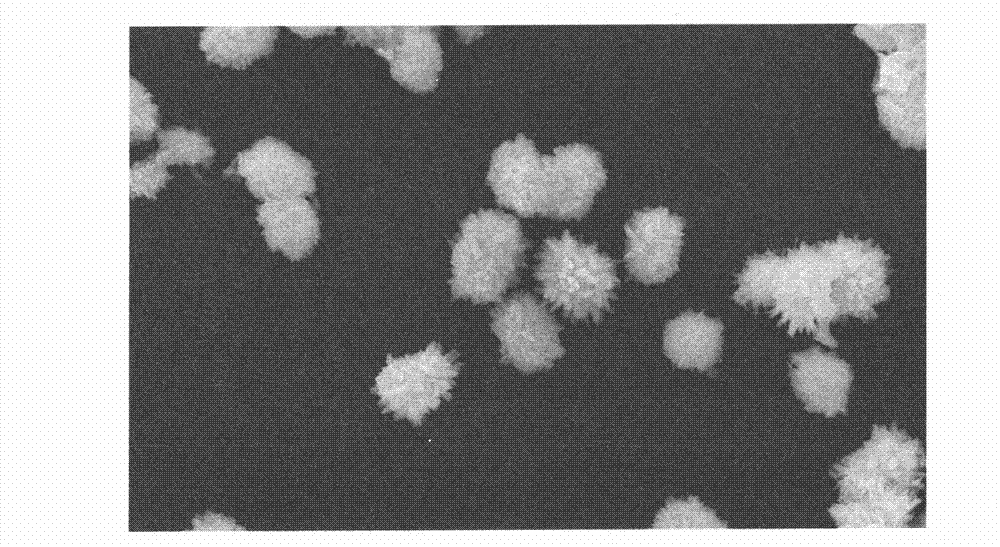

[0023] First prepare solution A: dissolve 0.1760g of europium oxide in 5ml of concentrated nitric acid, heat and stir until completely dissolved, continue heating until the solution is evaporated to dryness, then add 40ml of deionized water to obtain solution A; dissolve 0.6597g of sodium tungstate dihydrate in 40ml deionized water to obtain solution B; then add solution B dropwise to solution A to obtain a white turbid solution; the concentration of europium ions in the turbid solution is 0.01mol / L, and the concentration of tungsten ions is 0.02mol / L; add nitric acid and sodium hydroxide solution to adjust the pH of the solution to 2; then, add the obtained white turbid liquid into an autoclave, heat to 180°C, keep it warm for 24 hours, and naturally cool to room temperature; finally, filter the obtained product and dry it get red EuW 2 o 6 (OH) 3 Phosphor. The phosphor particles are...

Embodiment 2

[0025] A preparation method of red fluorescent powder for LED, comprising the steps of:

[0026] First prepare solution A: dissolve 0.0352g of europium oxide in 5ml of concentrated nitric acid, heat and stir until completely dissolved, continue heating until the solution is evaporated to dryness, then add 40ml of deionized water to obtain solution A; dissolve 0.1319g of sodium tungstate dihydrate In 40ml deionized water, solution B was obtained; then solution B was added dropwise to solution A to obtain a white turbid solution; the concentration of europium ions in the white turbid solution was 0.002mol / L, and the concentration of tungsten ions was 0.004mol / L; Add nitric acid and sodium hydroxide solution to adjust the pH of the solution to 3; then, add the obtained white turbid liquid into an autoclave, heat to 240°C, and keep it warm for 20 hours; naturally cool to room temperature; finally, filter and dry the obtained product You can get red EuW 2 o 6 (OH) 3 Phosphor.

Embodiment 3

[0028] A preparation method of red fluorescent powder for LED, comprising the steps of:

[0029] First prepare solution A: dissolve 0.88g of europium oxide in 5ml of concentrated nitric acid, heat and stir until completely dissolved, continue heating until the solution is evaporated to dryness, then add 40ml of deionized water to obtain solution A; dissolve 3.2985g of sodium tungstate dihydrate In 40ml of deionized water, solution B was obtained; then solution B was added dropwise to solution A to obtain a white turbid solution; the concentration of europium ions in the white turbid solution was 0.05mol / L, and the concentration of tungsten ions was 0.1mol / L; The pH of the solution was adjusted to 4 by adding nitric acid and sodium hydroxide solution; then, the obtained white turbid liquid was added to an autoclave, heated to 170° C., and kept for 72 hours; naturally cooled to room temperature; finally, the obtained product was filtered, Dry to get red EuW 2 o 6 (OH) 3 Phosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com