Method for preparing bismuthyl chloride nano-flower

A technology of bismuth oxychloride and nanoflowers, which is applied in chemical instruments and methods, inorganic chemistry, bismuth compounds, etc., can solve the problems of low output, difficult bismuth film, low output, etc., and achieve high catalytic activity, smooth feel, high effect on the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

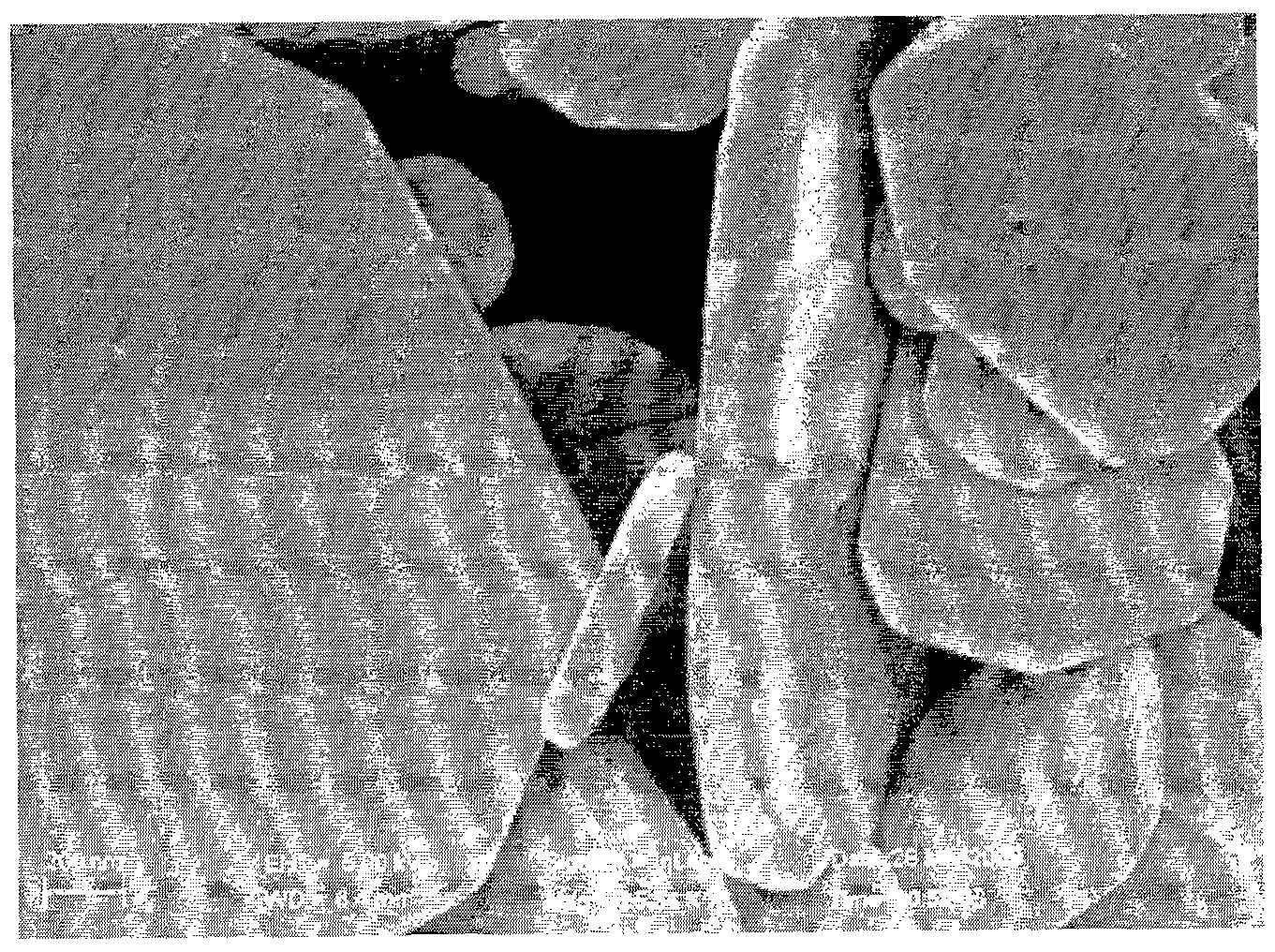

[0022] Embodiment 1: prepare bismuth oxychloride nanosheets with different wall thicknesses:

[0023] This step is a transitional stage for preparing the product bismuth oxychloride nanoflowers. (1) Dissolve 0.22 g of bismuth trichloride in 21 ml of water, stir for 30 minutes, transfer to a 25 ml autoclave with a polytetrafluoroethylene liner, and react at 180 degrees Celsius for 12 hours. (2) Dissolve 0.22 gram of bismuth trichloride in 14 milliliters of water and 7 milliliters of pyridine mixed solutions, after stirring for 30 minutes, transfer to 25 milliliters of autoclaves with polytetrafluoroethylene liners, and react at 180 degrees Celsius 12 hours. (3) Dissolve 0.22 gram of bismuth trichloride in 7 milliliters of water and 14 milliliters of pyridine mixed solutions, after stirring for 30 minutes, transfer to 25 milliliters of autoclaves with polytetrafluoroethylene liners, and react at 180 degrees Celsius 12 hours. The product obtained above was washed by centrifuga...

Embodiment 2

[0029] Embodiment 2: Preparation of bismuth oxychloride nanoflowers:

[0030] Dissolve 0.22 g of bismuth trichloride in 21 ml of pyridine, stir for 30 minutes, transfer to a 25 ml autoclave with a polytetrafluoroethylene liner, and react at 180 degrees Celsius for 12 hours. The obtained product was washed by centrifugation for three times and then dried for characterization and testing.

[0031] The phase of the sample was characterized by Philips X'Pert PRO SUPER X-ray diffractometer (XRD), the morphology of the sample was characterized by the field emission scanning electron microscope of German Zeiss Company, the simulated sunlight photocatalytic test system and Shimadzu-2550 The photocatalytic properties of the samples were tested, and the specific surface and micropore distribution of the samples were analyzed by the automatic microporous physical adsorption and chemical adsorption analyzer of Micromeritics Instrument Company of the United States.

[0032] Figure 4 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com