Preparation method of phosphorus pentasulfide

A technology of phosphorus pentasulfide and yellow phosphorus, which is applied in the field of preparation of phosphorus pentasulfide by the liquid phase method, can solve the problems of low product quality, insufficient purity of the final product, complicated preparation process, etc., and achieve improved product yield, improved thermal stability and Antioxidant, side effect reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

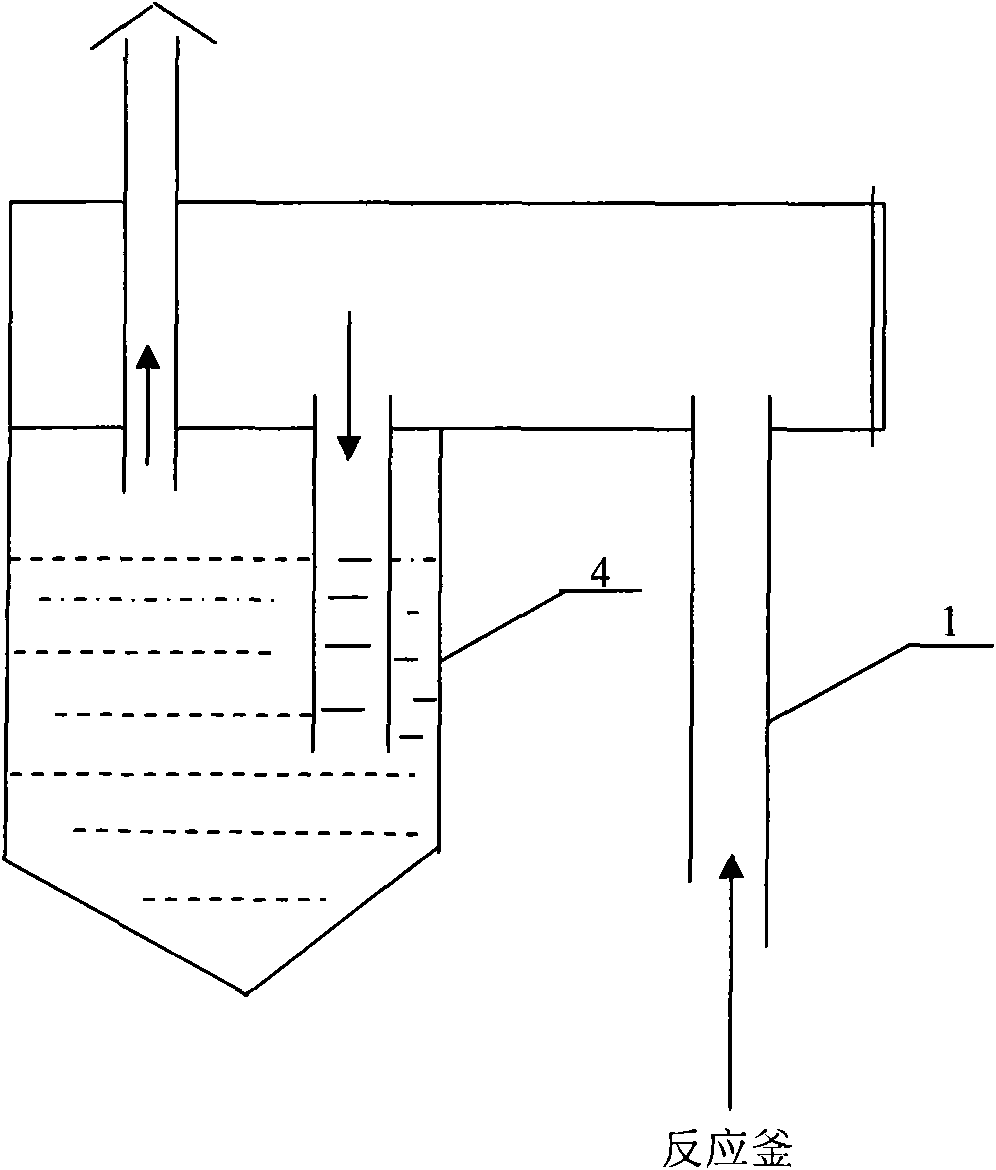

Image

Examples

Embodiment 1-6

[0031] Embodiment 1-6: the comparison of feeding mode change

[0032] Table 1

[0033]

[0034] As can be seen from Table 1, under substantially the same reaction conditions, the feeding methods are different and the product yields are different. Adopting the nozzle type feeding of the present invention can improve the product yield by 7-8% compared with the straight pipe feeding.

[0035] In Examples 7-18, the nozzle-type feeding method was adopted, and the experimental results under the control of different process parameters were compared.

[0036] The results are shown in Table 2 and Table 3.

[0037] Table 2

[0038] parameter control

[0039] table 3

[0040] parameter control

[0041] Reactor liquid level%

[0042] Find out by table 2 and table 3, the product of higher purity has been obtained in the scope of the selected reaction conditions and distillation conditions of the present invention, and product purity can be up to more tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com