Compound foamed aluminum particle board and manufacturing process thereof

A composite foam and manufacturing process technology, applied in the direction of layered products, etc., can solve the problems of low yield of aluminum foam boards, increased production costs, and increased processing procedures, and achieve high production efficiency, reduced production costs, and improved mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

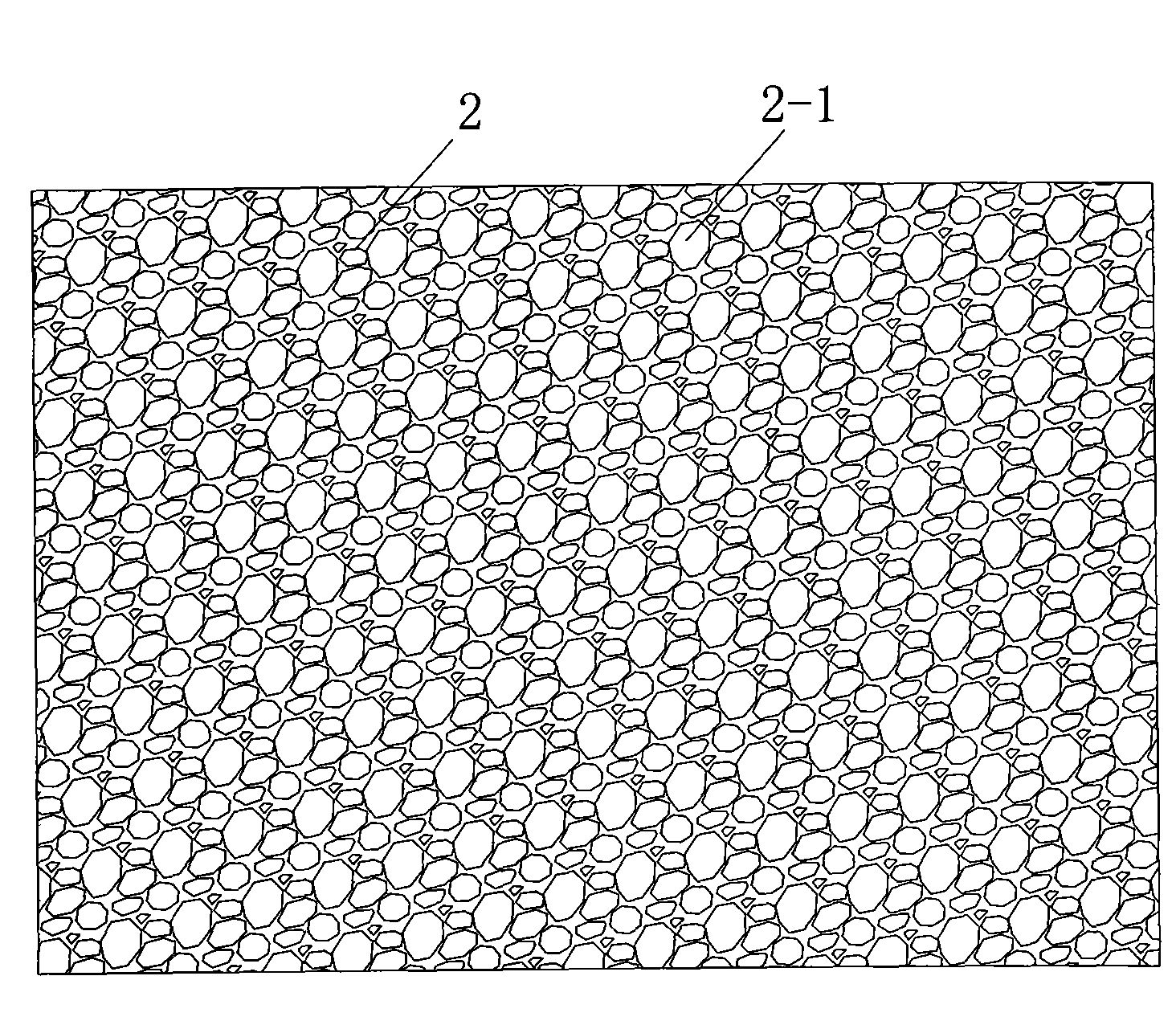

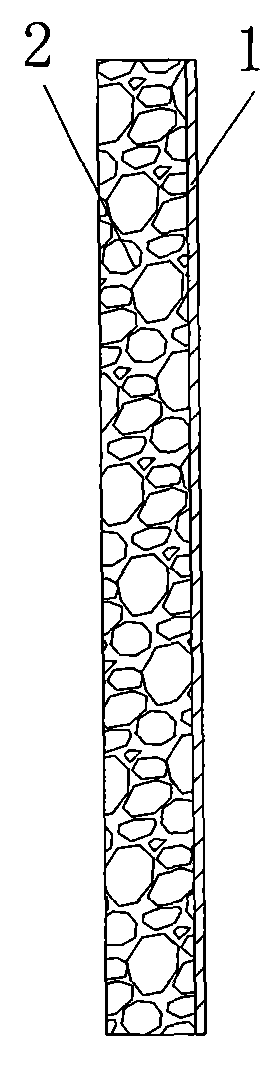

[0042] Single-sided composite foamed aluminum particle board, one of which is composited with mesh or perforated board; structure such as figure 1 , figure 2 shown.

Embodiment 2

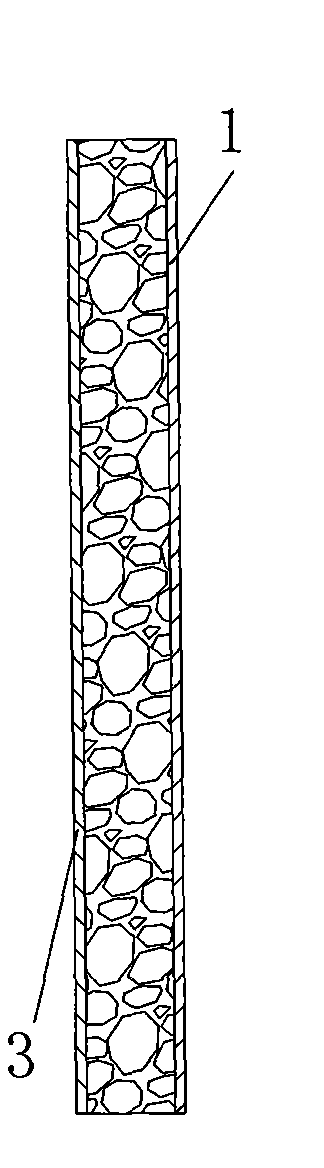

[0044] Double-sided composite foamed aluminum particle board, the two planes are compounded with mesh panels or perforated panels; the structure is as follows image 3 shown.

[0045] The net plate ( Figure 4 shown) or perforated plate ( Figure 5 Shown) can be purchased directly, and the specifications of the screen or perforated plate can be determined according to the needs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com