Crankshaft driving mechanism of press machine

A crankshaft drive and press technology, which is applied to the driving device of forging presses, presses, stamping machines, etc., can solve the problems of gear wear, unbalanced load, large torque, etc., and achieve less impact and reduce gear damage Accidents, reducing the effect of uneven local stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

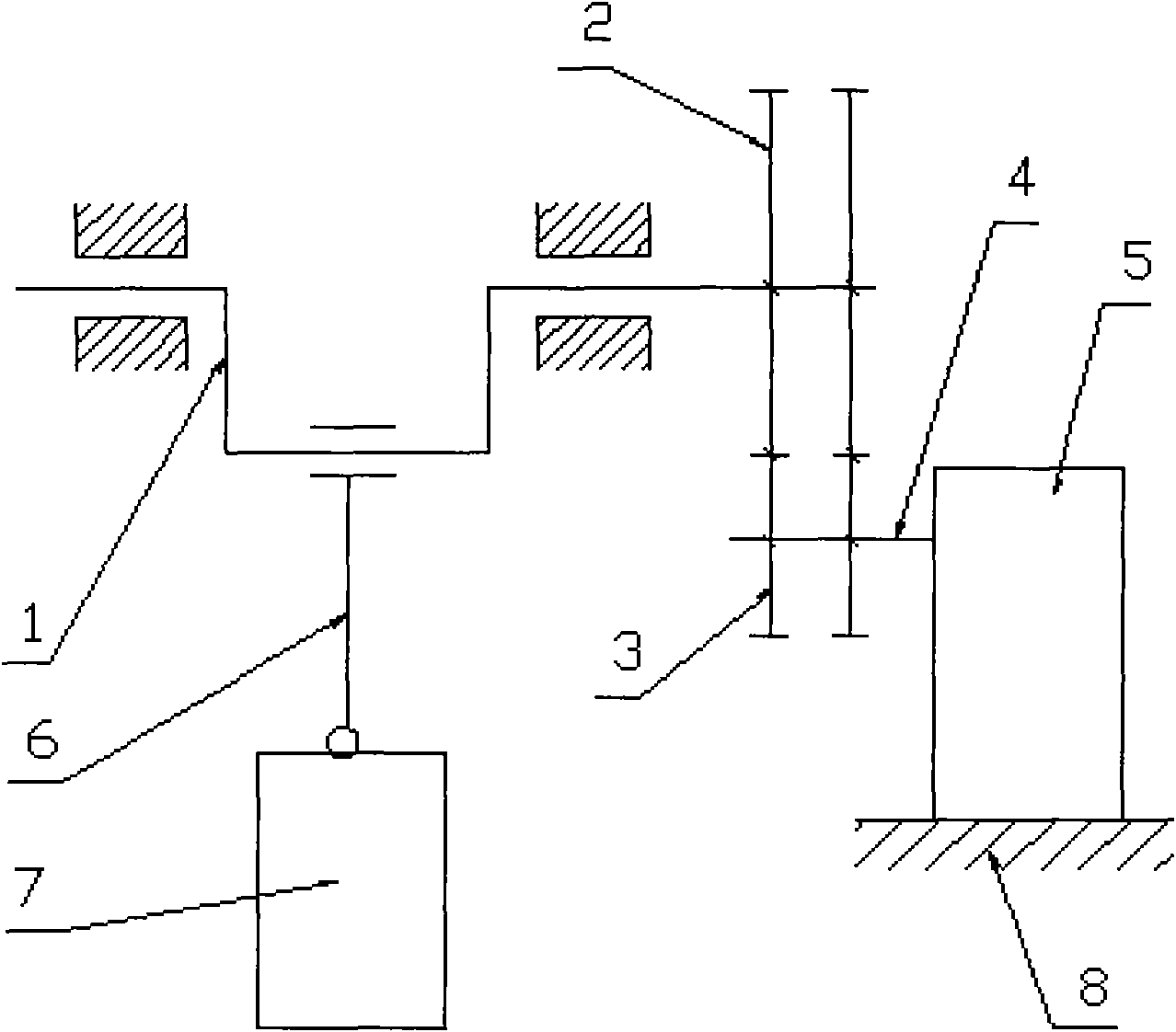

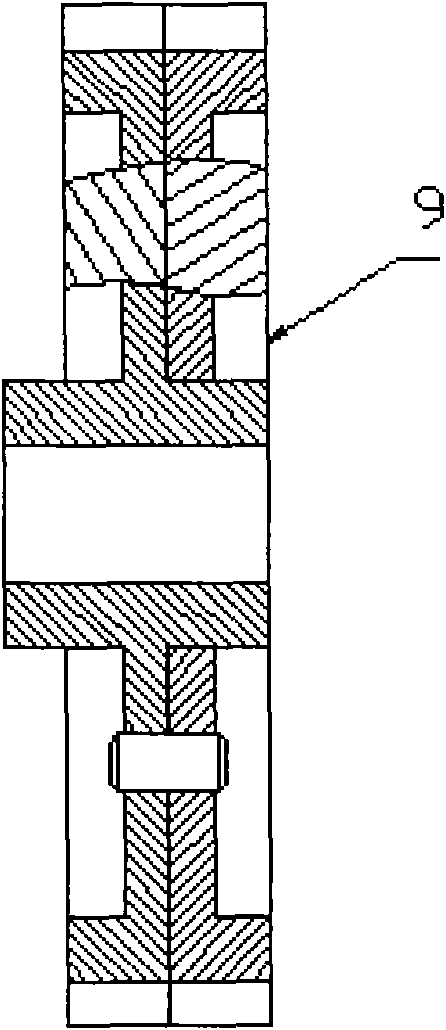

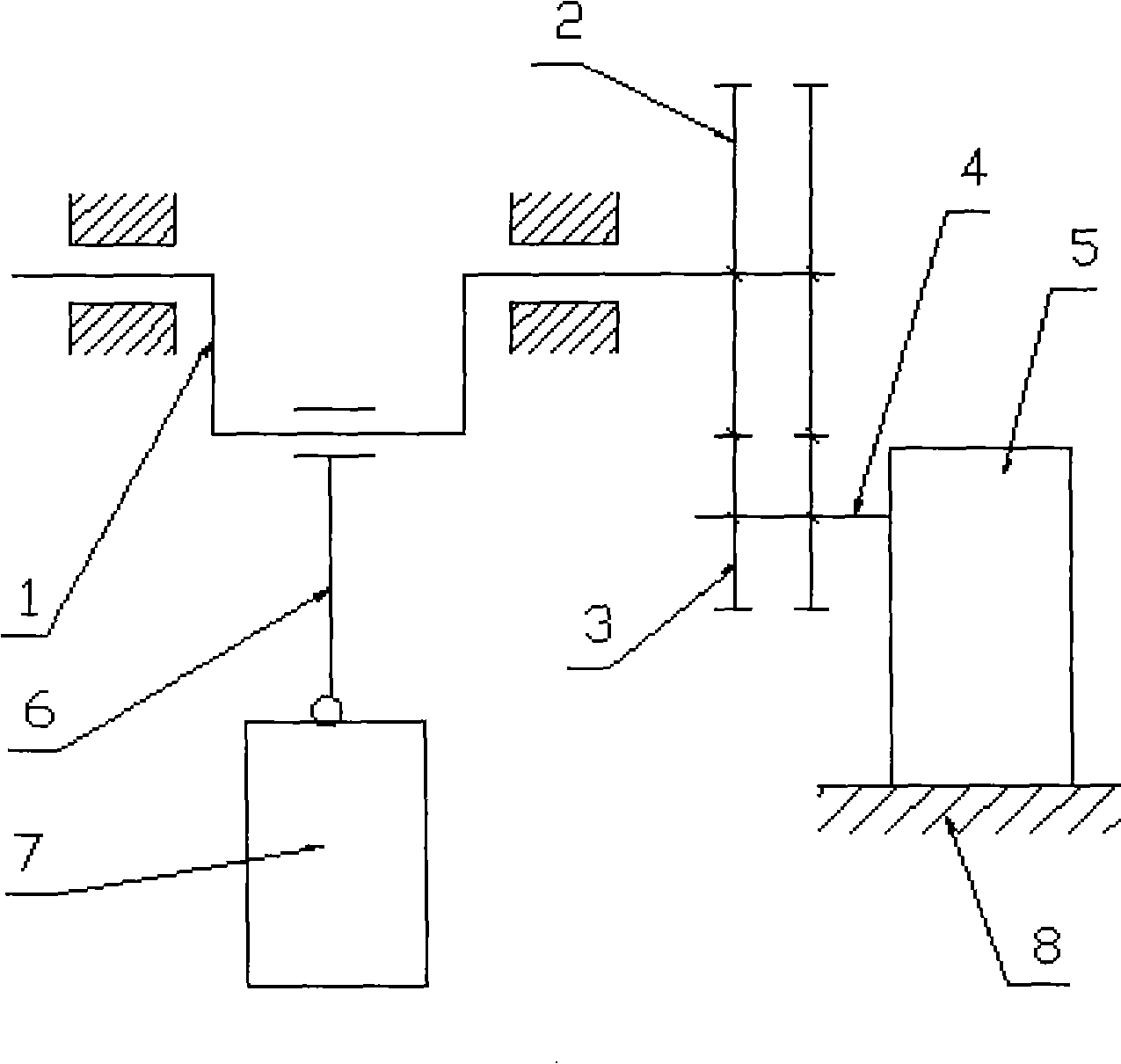

[0009] Correctly install the double herringbone gear (2) at the crankshaft end on the top of the crankshaft (1), correctly install the double herringbone gear (3) at the output shaft end of the gearbox on the top of the output shaft (4) of the gearbox, and place the gear The box (5) is installed on the bed (8) of the press, and the double herringbone gear (2) at the end of the crankshaft is properly meshed with the double herringbone gear (4) at the output shaft end of the gearbox. Correctly install the connecting rod (6) with the crankshaft (1), correctly connect the connecting rod (6) with the slider (7), and install other transmission parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com