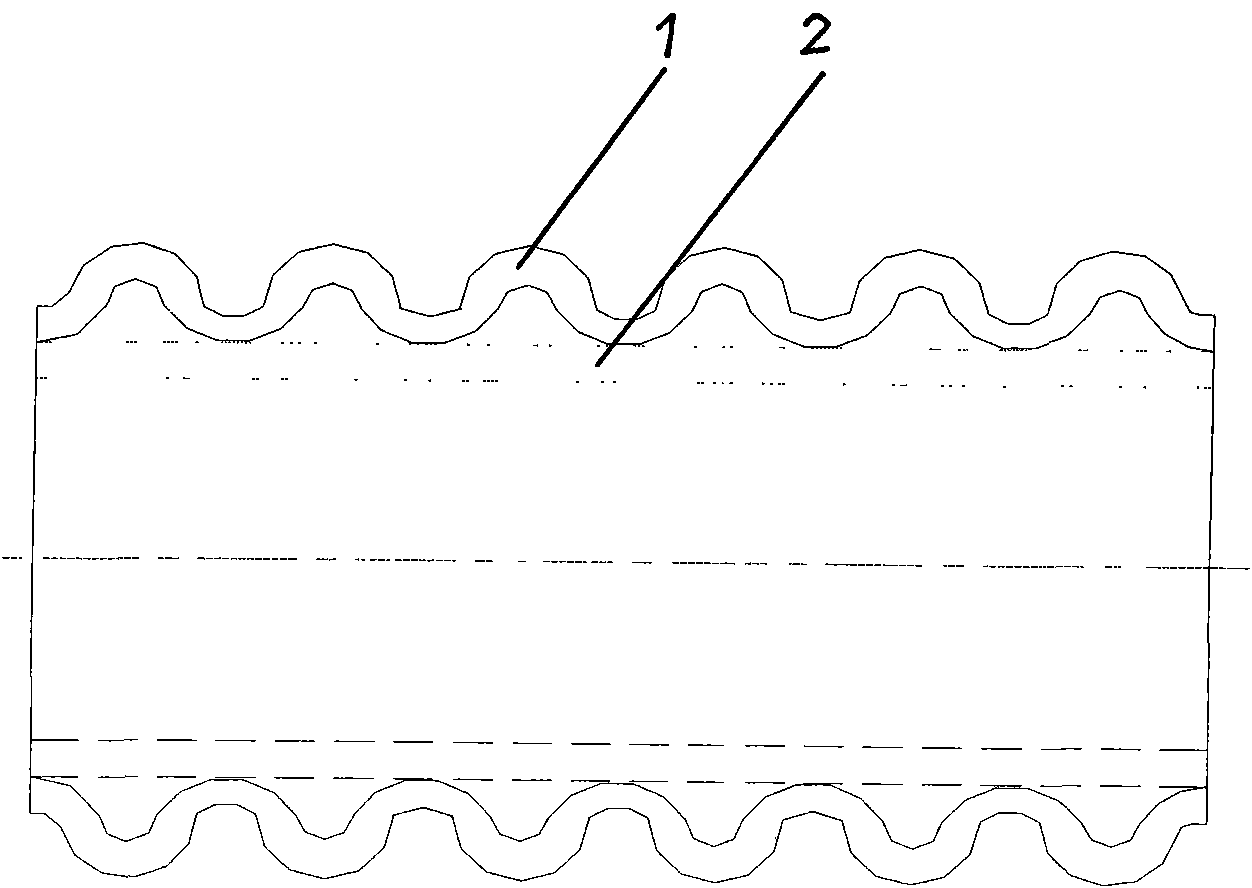

Plastic double-wall winding corrugated pipe forming device

A forming device and winding device technology, applied in the field of plastic double-wall winding corrugated pipe forming device, can solve the problems of not being suitable for the production of large-diameter pipes, unstable product quality and service life, etc., to shorten the processing cycle, reduce investment in equipment, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

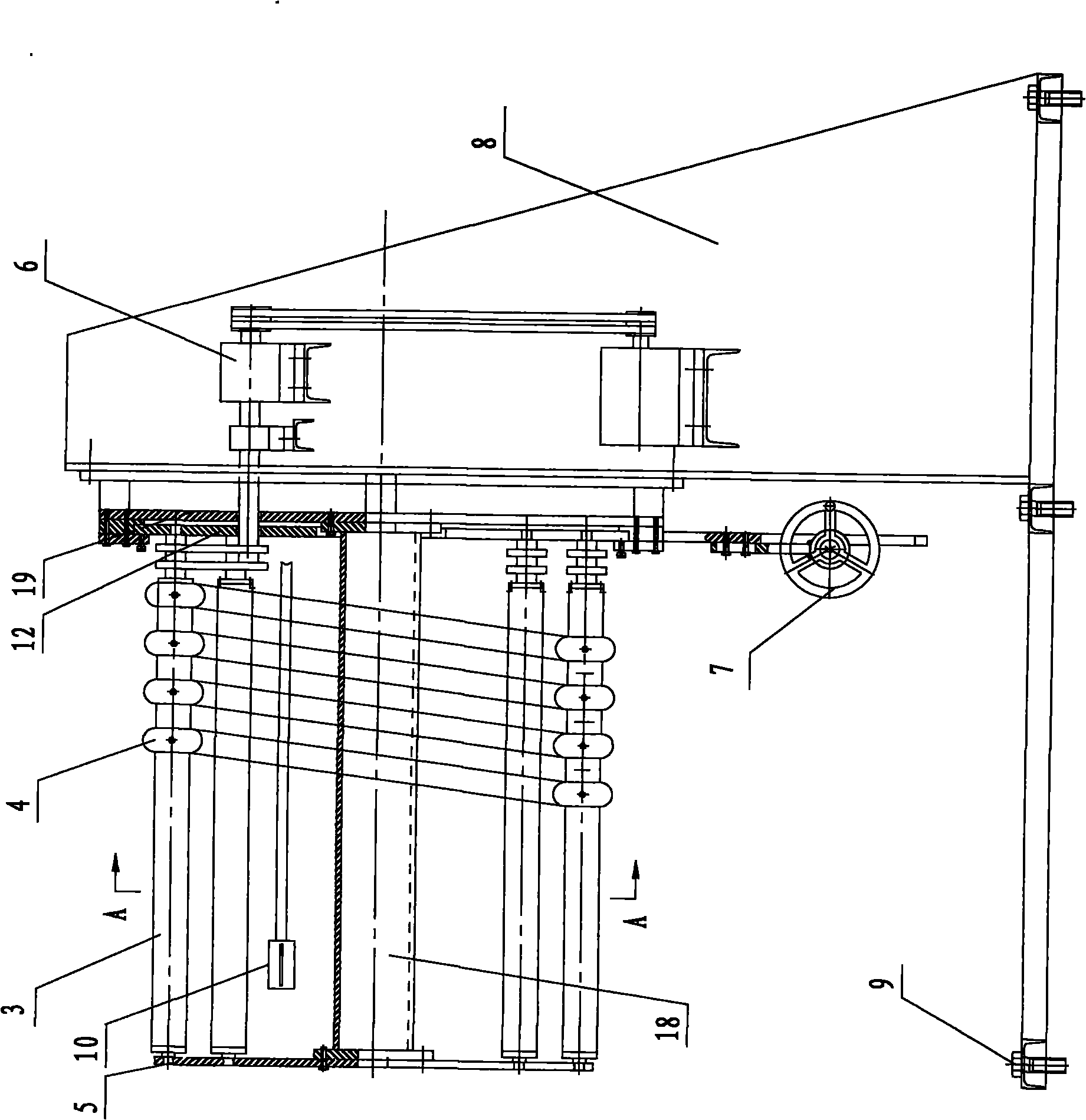

[0022] The specific embodiments of the present invention will be further described with reference to the accompanying drawings.

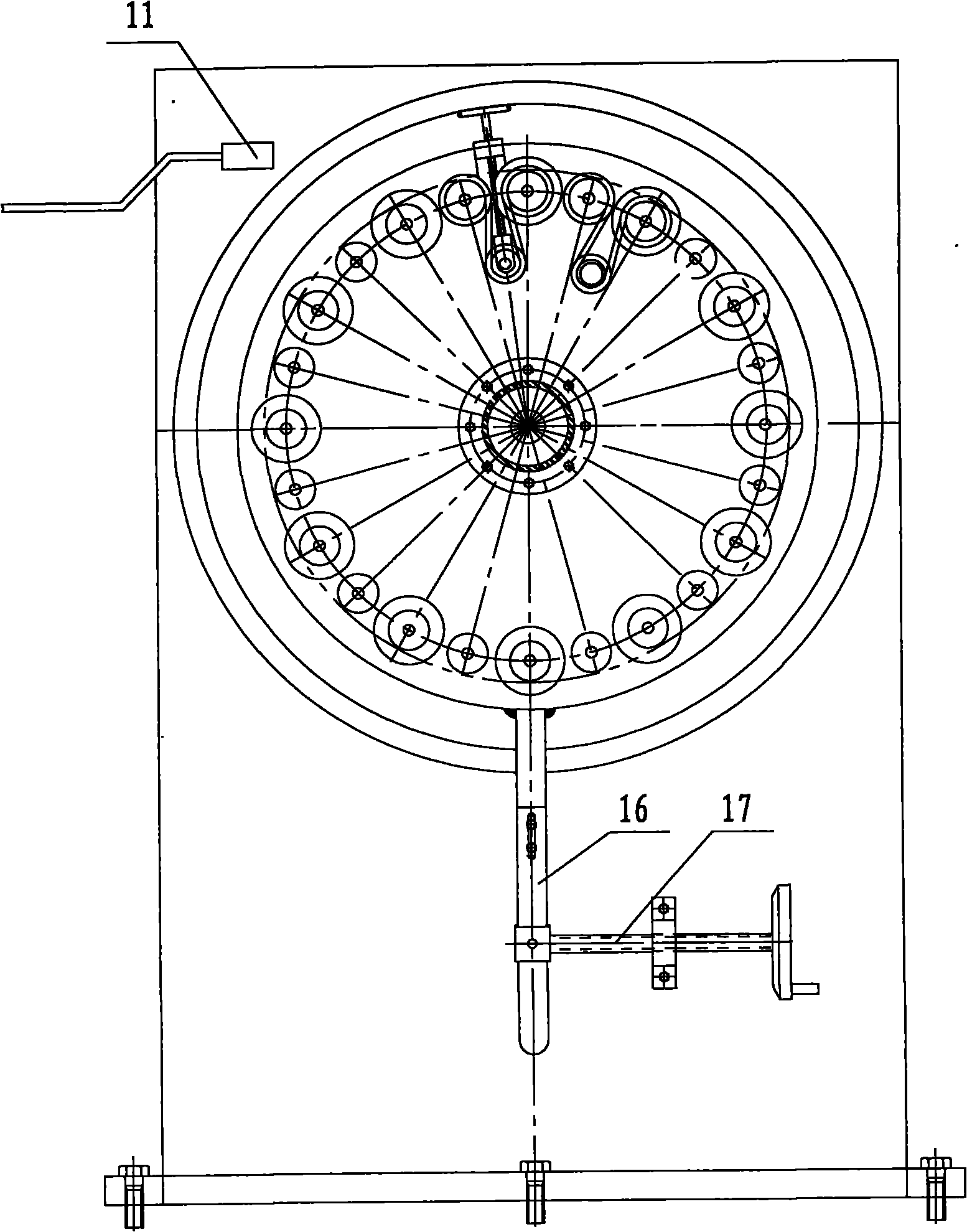

[0023] Plastic double wall corrugated pipe winding equipment such as figure 2 , image 3 shown. The equipment consists of a bulge winding device, front and rear brackets, a power transmission device, a rotating mechanism, and a screw adjustment part. The specific structure is as follows:

[0024] 1) The uplift winding device includes a circular stick group, and a plurality of circular sticks 3 are formed into a circular stick group evenly arranged in a circle, and the diameter of the circumscribed circle of the circular stick group matches the inner diameter of the plastic pipe. Due to the phenomenon of cold shrinkage during the processing of the plastic tube, the design diameter of the circumscribed circle is slightly larger than the diameter of the product plastic tube, the front and rear diameters of the circle are also different, and the dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com