Blow molding machine and associated mechanisms

一种机器、模具的技术,应用在吹塑机和相关机构领域,能够解决影响模制容器质量等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

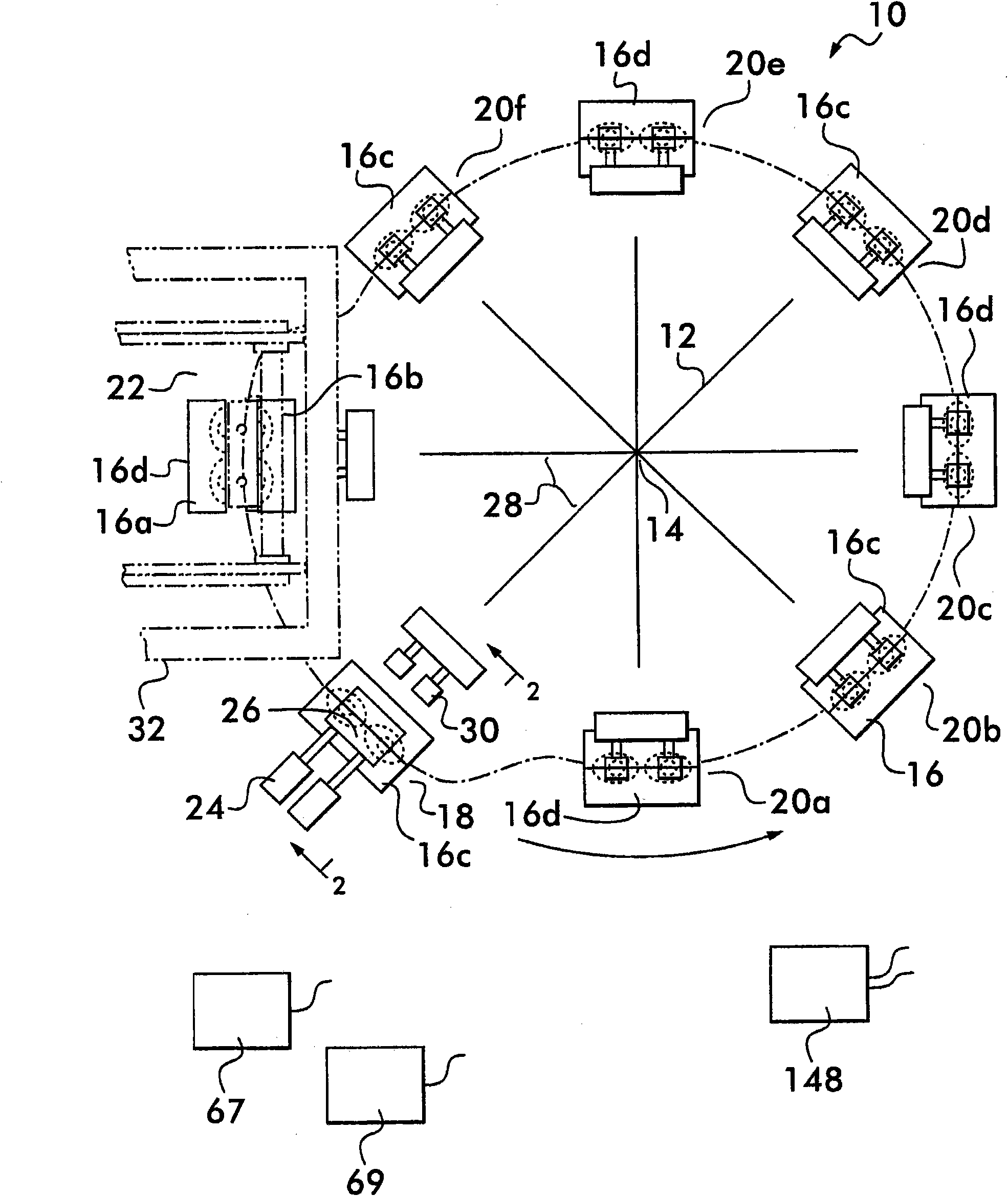

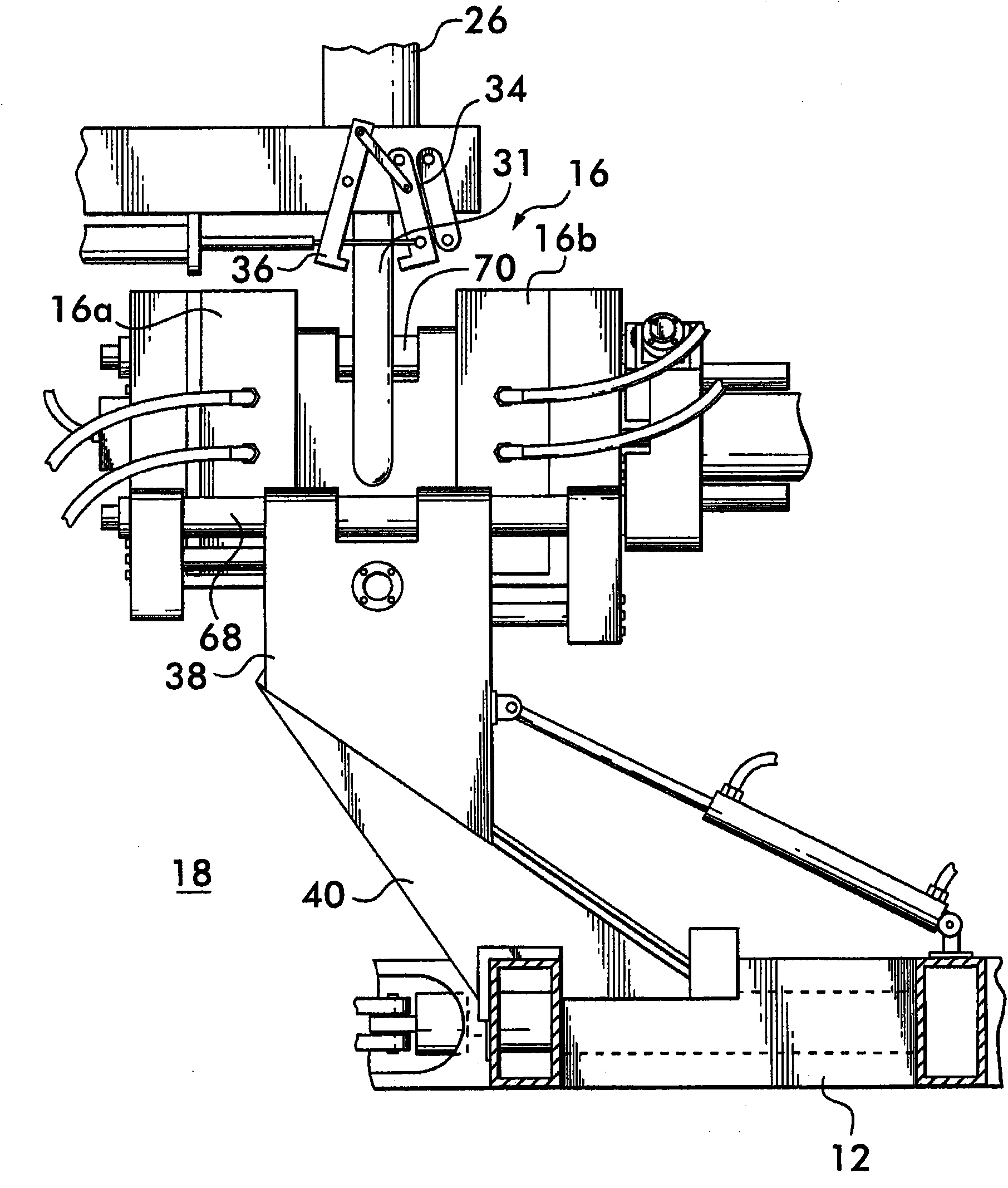

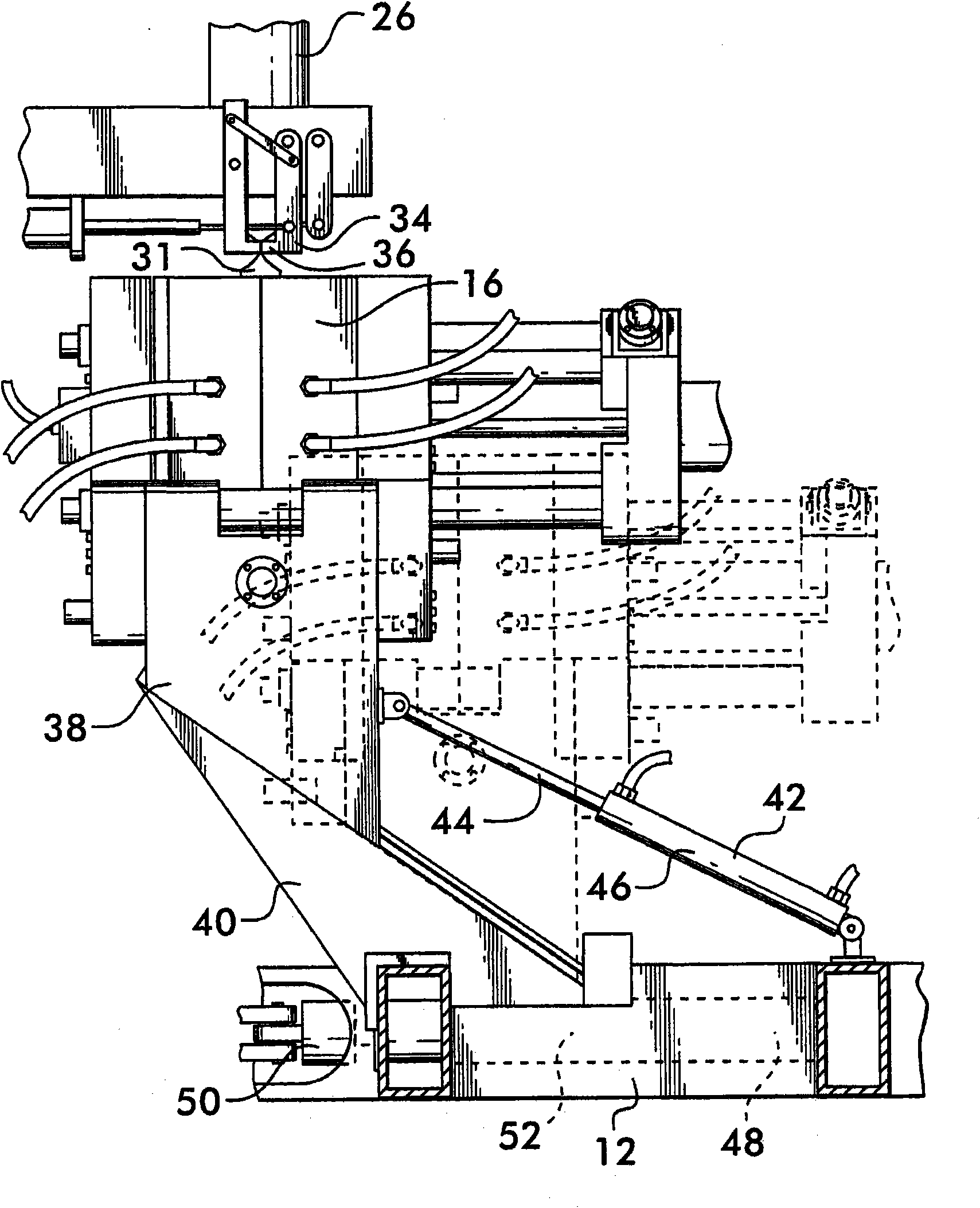

[0057] Referring now to the drawings, wherein like reference numerals designate like elements throughout the different figures constituting the drawings, figure 1 A schematic plan view of an exemplary blow molding machine 10 according to the present invention is shown. Machine 10 includes a turntable 12 rotatable about an axis of rotation 14 by an electric motor (not shown). Preferably, the turntable 12 is oriented horizontally and the axis of rotation 14 is substantially vertical.

[0058] On the turntable 12 are mounted one or more molds 16 . Rotation of the turntable 12 sequentially positions each mold 16 in a counterclockwise direction at a plurality of stations including a first station 18 , a plurality of intermediate stations 20 a - 20 f , and a final station 22 . The number of workstations is equal to the number of molds 16 on the turntable 12, eight in this example, but more or fewer workstations are possible. Each mold 16 includes two mold parts 16a and 16b that c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com