Genetic optimization controlling technology of piler

A technology of genetic optimization and control technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., to achieve the effect of reducing the amount of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, illustrate the genetic optimization control technology that the present invention proposes for automatic three-dimensional warehouse stacker, its specific implementation method is as follows:

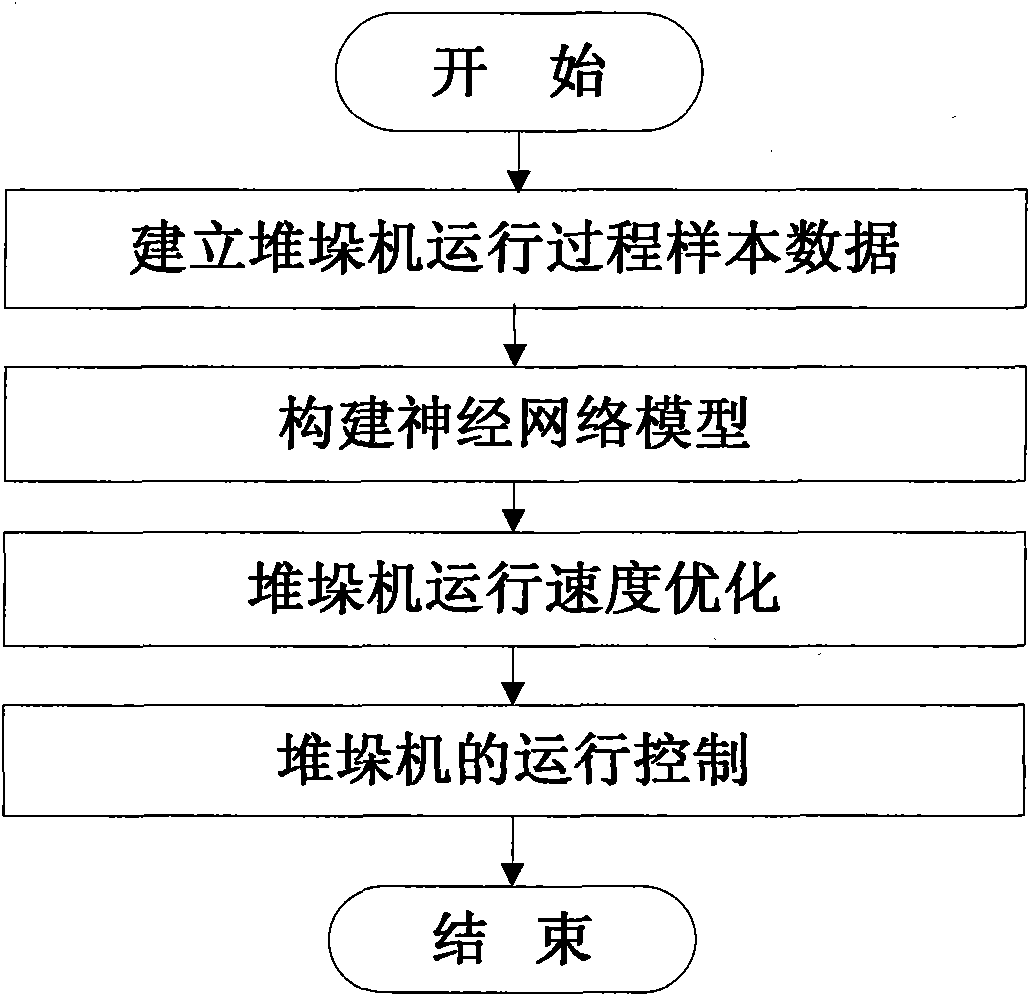

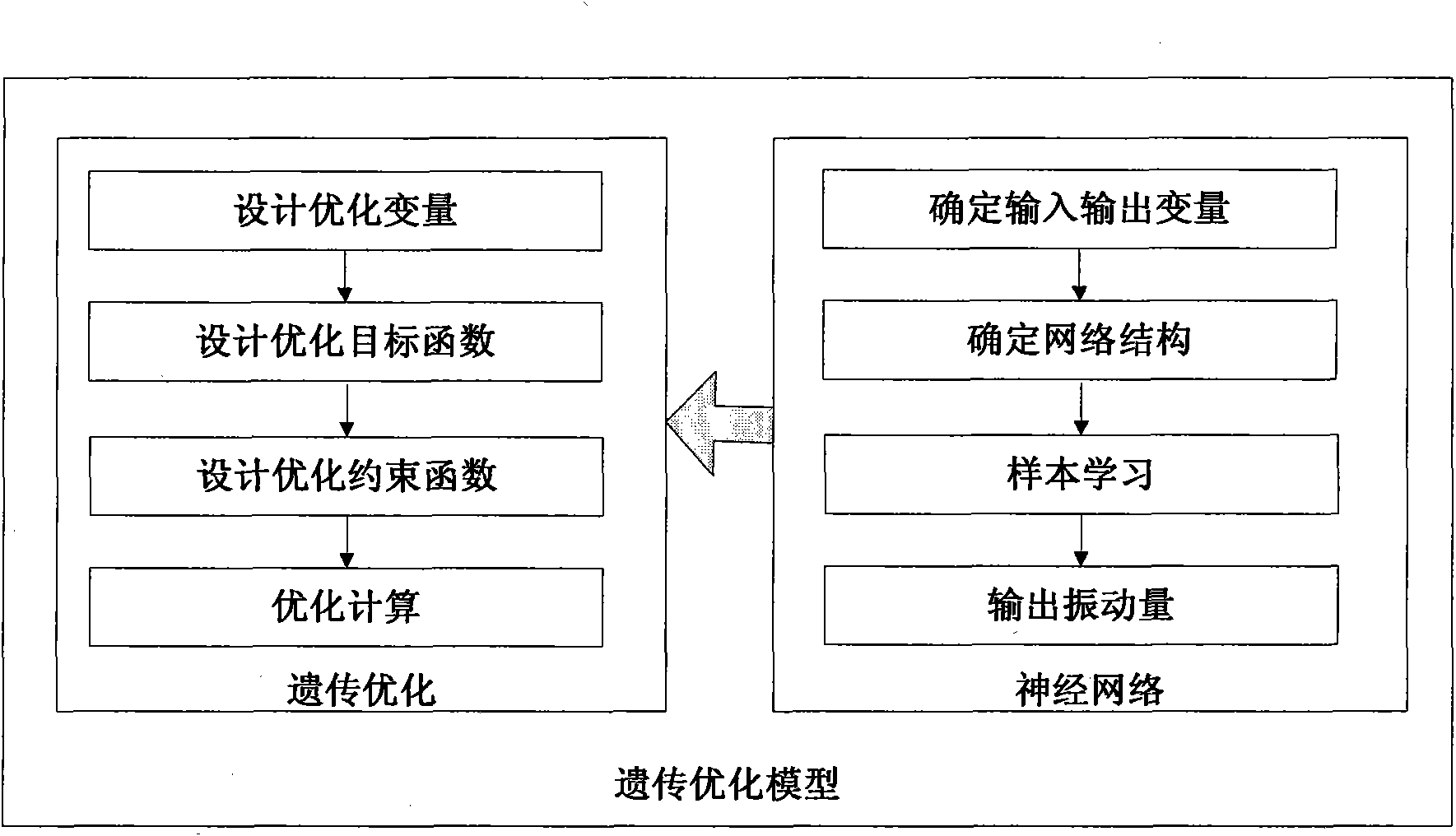

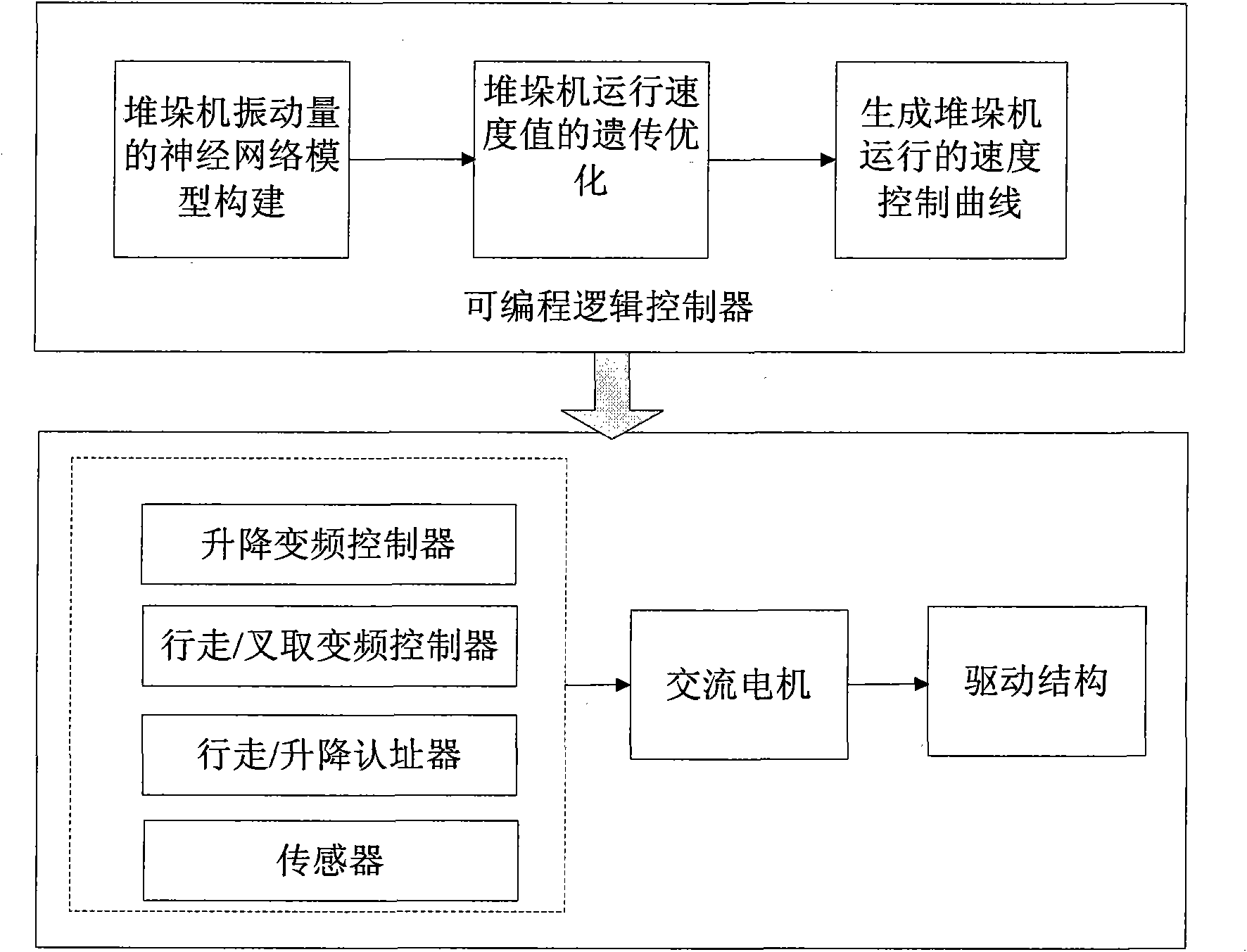

[0021] figure 1 It is a stacker crane evolution optimization control flow chart. The new stacker control technology proposed by the present invention uses neural network and genetic algorithm as a means to reduce the amount of vibration generated during the high-speed operation of the stacker. Speed-optimized control of the running process. In order to achieve the above-mentioned goals, the technical solution adopted by the present invention is: based on the main operating parameters and the vibration data generated during the operation of the stacker, the relationship between the vibration state of the stacker and the main operating parameters is established. Neural network mapping model; based on the established neural network mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com