Motorcycle oil-gas separator

A technology of oil and gas separators and motorcycles, which is applied in the direction of machine/engine, engine components, engine lubrication, etc., can solve the problems of air pollution, violation, and limited adsorption capacity of carbon tanks, so as to avoid entering carbon tanks and make the manufacturing process simple , The effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

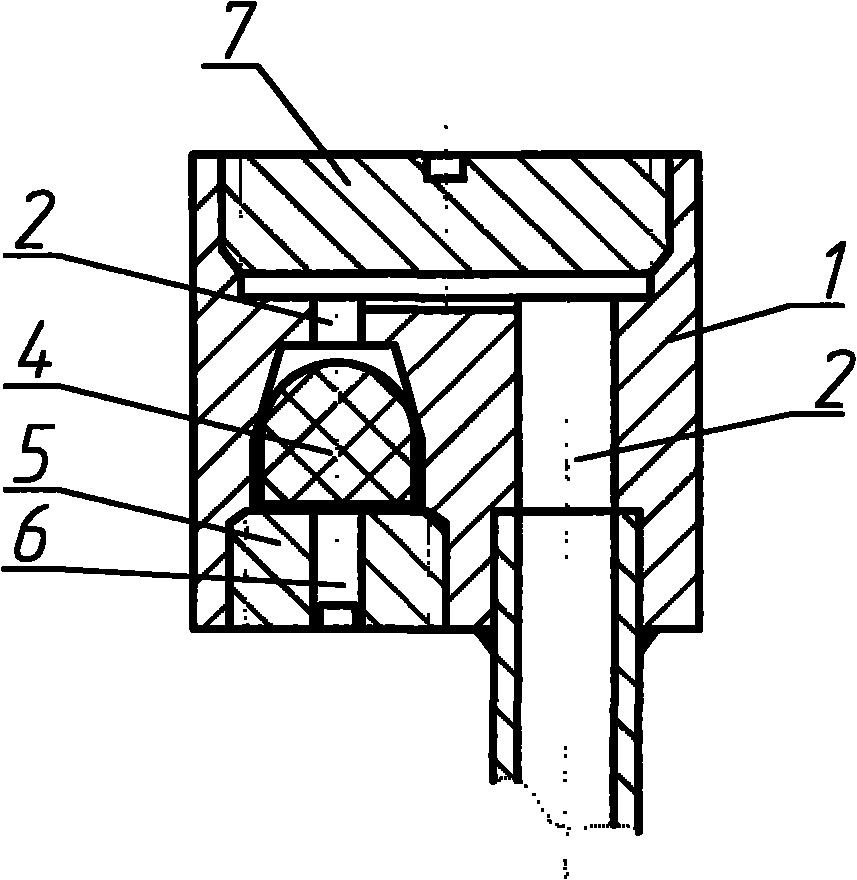

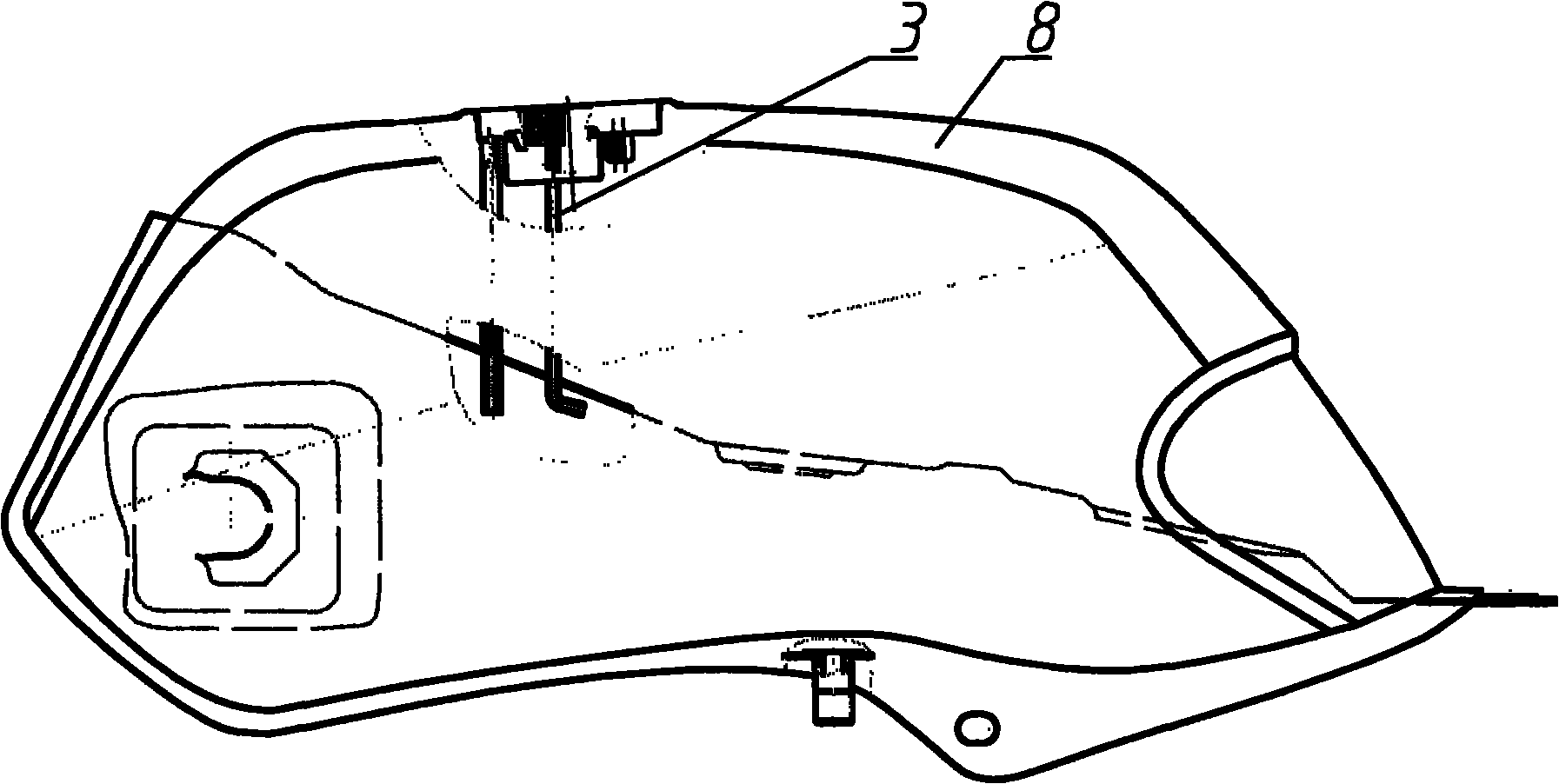

[0016] see figure 1 , as can be seen from the figure, the motorcycle oil-gas separator of the present invention includes a separator body 1, and an oil vapor passage 2 is arranged in the separator body 1, the inlet of the oil vapor passage 2 is a bell mouth, and the outlet of the oil vapor passage 2 Connect with the carbon canister through the oil vapor vent pipe 3. A float 4 is arranged in the bell mouth, and the float is a non-metallic part whose density is lower than that of fuel oil. The limiter 5 is threadedly connected to the bell mouth of the separator body 1, and usually the float falls on the limiter. A through hole 6 is provided at the center of the limiting member 5, and a ventilation groove is provided on the bottom surface of the float, and the ventilation groove communicates with the through hole. Once fuel oil enters the through hole of the limiting member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com