Rare earth fluorescent powder and preparation method thereof

A rare earth phosphor and a manufacturing method technology, applied in chemical instruments and methods, luminescent materials, sustainable buildings and other directions, can solve problems such as insufficient light decay, and achieve the effects of improving light decay, increasing temperature quenching, and reducing synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

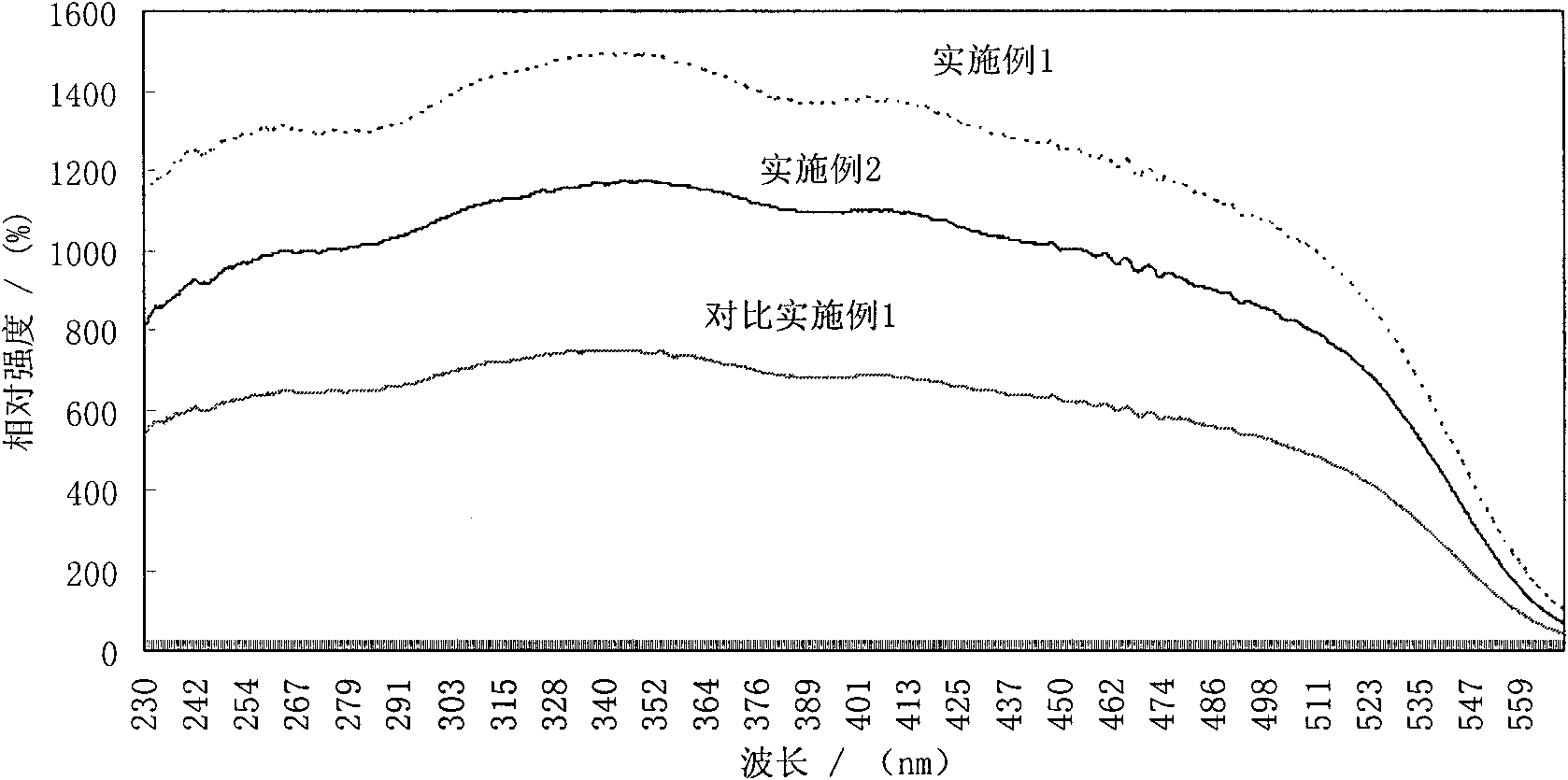

Embodiment 1

[0049] Firstly, 94.86 g of ammonium bicarbonate was weighed to prepare a 25% aqueous solution, and heated to 45° C. in a water bath. Then weigh Sr(NO 3 ) 2 207.39g, Ba(NO 3 ) 2 4.36g, La(NO 3 ) 3 0.27g, Eu(NO 3 ) 3 0.9g, SiO 2 15g was added to deionized water to prepare a suspension with a concentration of 0.5%. Add the suspension to the ammonium bicarbonate solution, keep it warm for 45 minutes while stirring, then separate the suspension from water and powder, wash the powder cake until neutral, and then use deionized Water redisperses the separated powder cake and prepares a suspension with a mass percentage of 35%. Add 0.022 g of LiF to the suspension, ultrasonically disperse for 3 minutes, and then stir for 20 minutes, then dry the suspension, and disperse the dried powder cake to obtain the reaction precursor of the fluorescent powder. The reaction precursor was placed in a furnace with a reducing atmosphere and heated to 1400°C. After a holding time of 4 hours,...

Embodiment 2

[0052] Firstly, 126 g of ammonium bicarbonate was weighed to prepare a concentration of 8% aqueous solution, and heated to 55° C. in a water bath. Then weigh Sr(NO 3 ) 2 202.1g, Ba(NO 3 ) 2 8.71g, La(NO 3 ) 3 1.08g, Eu(NO 3 ) 3 2.82g, SiO 2 19g was added to deionized water to prepare a suspension with a concentration of 1.15%, and the suspension was added to the ammonium bicarbonate solution, kept stirring for 60 minutes, and then the suspension was separated from water and powder, and the powder cake was washed until neutral, and then deionized Water redisperses the separated powder cake and prepares a suspension with a mass percentage of 45%. Add 0.05 g of NaF to the suspension, ultrasonically disperse for 5 minutes, and then stir for 30 minutes, then dry the suspension, and disperse the dried powder cake to obtain the reaction precursor of the fluorescent powder. The reaction precursor was placed in a reducing atmosphere furnace and heated to 1450°C. After a holdin...

Embodiment 3

[0054] Firstly, 158g of ammonium bicarbonate was weighed to prepare an 8% aqueous solution, and heated to 55°C in a water bath. Then weigh Sr(NO 3 ) 2 197.66g, Ba(NO 3 ) 2 10.45g, Gd(NO 3 ) 3 1.32g, Eu(NO 3 ) 3 6.2g, SiO 2 18g is added to deionized water and is mixed with concentration and is 10.5% suspension, wherein SiO The purity is 99.9%, and the powder particle diameter d50 is 2.5 microns, and d90 is less than 5 microns, and the suspension is added and added in the ammonium bicarbonate solution, while Stir and keep warm for 60 minutes, then separate the suspension from water and powder, wash the powder cake to neutrality, redisperse the separated powder cake with deionized water and prepare a suspension with a mass percentage of 38%. Add 0.28 g of NaF to the suspension, ultrasonically disperse for 7 minutes, and then stir for 28 minutes, then dry the suspension, and disperse the dried powder cake to obtain the reaction precursor of the fluorescent powder. The rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com