Method for stabilizing furfurylglycidylether or ester- carbon dioxide copolymer

A technology of furfuryl glycidyl ether and carbon dioxide, which is applied in the field of stabilizing furfuryl glycidyl ether or ester-carbon dioxide copolymer, to achieve the effect of simple and easy method and improvement of crosslinking and discoloration problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

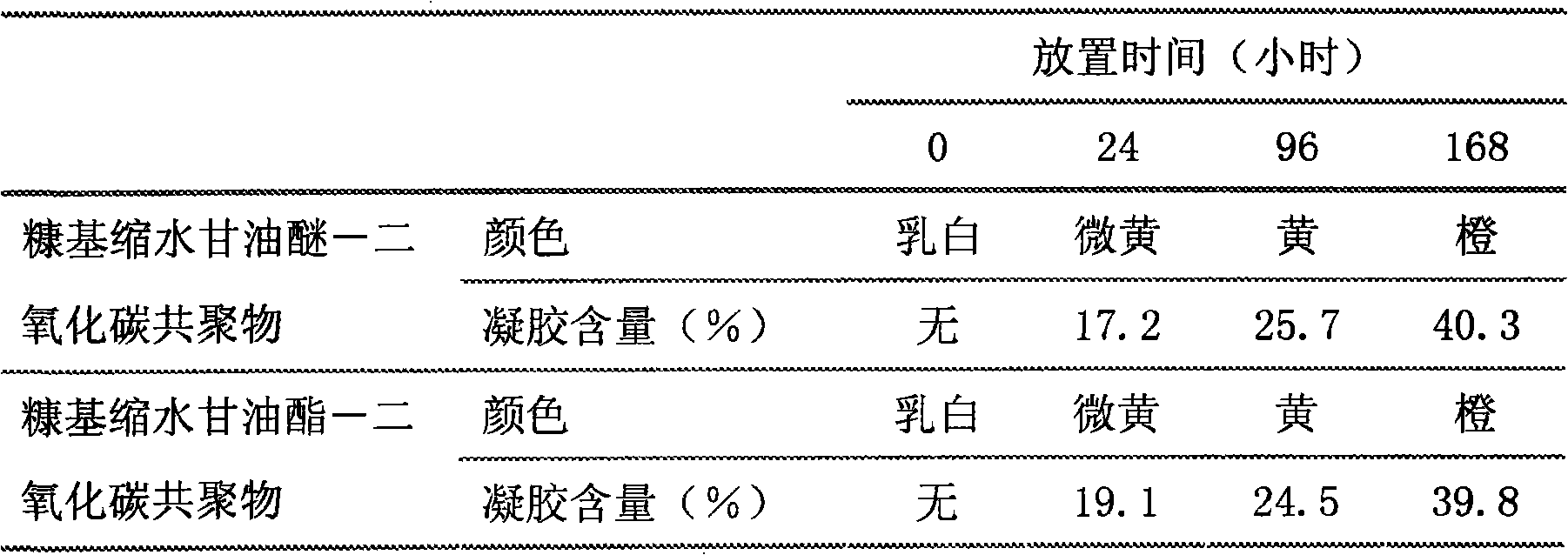

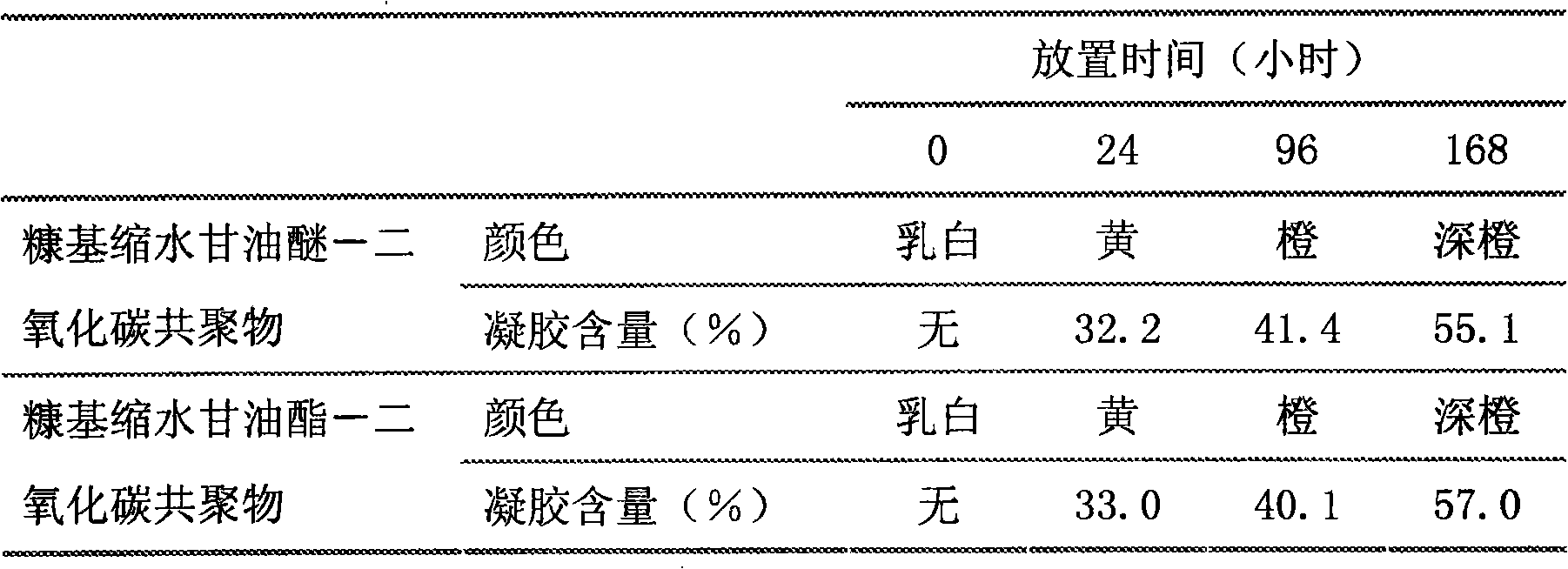

[0028] Embodiment 1 Weigh 5.0g furfuryl glycidyl ether-carbon dioxide copolymer (Mn=13.3×10 4 g / mol; Tg=-1.5°C) was dissolved in 25 g of dichloromethane under stirring at 80 to 100 rpm, and then 0.15 g of 2,4,6-tri-tert-butylphenol was added to the formed polymer solution , that is, antioxidant 246, blended for 1.5 hours under stirring at 80-100 rpm. The polymer solution added with antioxidant was concentrated at 40°C to 1.33KPa in vacuum until no solution dripped out, and then dried in a vacuum oven at 40°C to constant weight.

[0029] The obtained furfuryl glycidyl ether-carbon dioxide copolymer mixed with antioxidant 264 was left in the air at 40° C. for 168 hours without gel and color change, and the color was milky white.

Embodiment 2

[0030] Embodiment 2 Weigh 10.0g furfuryl glycidyl ether-carbon dioxide copolymer (Mn=14.5×10 4 g / mol; Tg=-2.3°C) was dissolved in 50 g of acetone under stirring at 80 to 100 rpm, and then 0.1 g of tetrakis (3,5-di-tert-butyl-4- Hydroxy) pentaerythritol phenylpropionate, i.e. antioxidant 1010 and 0.1g two (2,4-di-tert-butylphenyl) pentaerythritol diphosphite, i.e. antioxidant 626, under the stirring of 80~100rpm, altogether Mix for 1.5 hours. The polymer solution added with antioxidant was concentrated at 40°C to 1.33KPa in vacuum until no solution dripped out, and then dried in a vacuum oven at 40°C to constant weight.

[0031] The obtained furfuryl glycidyl ether-carbon dioxide copolymer mixed with antioxidant 1010 and antioxidant 626 was left in air at 40° C. for 168 hours without gel formation and color change.

Embodiment 3

[0032] Embodiment 3 Weigh 10.0g furfuryl glycidyl ester-carbon dioxide copolymer (Mn=14.5×10 4 g / mol; Tg=-6.5°C) was dissolved in 50 g of dimethyl carbonate under stirring at 80 to 100 rpm, and then 0.3 g of 2,6-di-tert-butyl-p-cresol was added to the formed polymer solution , that is, antioxidant 246, blended for 1.5 hours under stirring at 80-100 rpm. The polymer solution added with antioxidant was concentrated at 40°C to 1.33KPa in vacuum until no solution dripped out, and then dried in a vacuum oven at 40°C to constant weight.

[0033] The obtained furfuryl glycidyl ester-carbon dioxide copolymer mixed with antioxidant 264 was left in air at 40° C. for 168 hours without gel formation and color change.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com