Method and equipment for producing elementary silicon

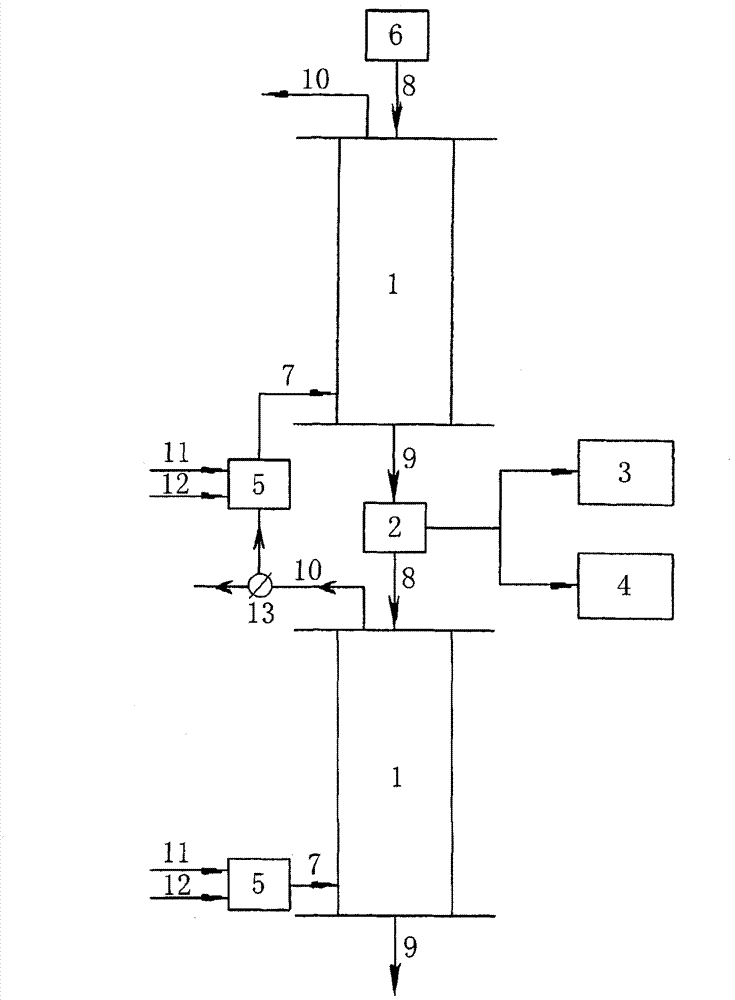

A production method and production equipment technology, applied in the field of simple silicon, can solve the problems of increased production complexity, production cost and energy consumption, small specific surface area of silicon rod deposition, low primary conversion rate of raw materials, etc., so as to save labor and operation Cost and energy consumption and waste, reduced possibility of secondary pollution, and high internal space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

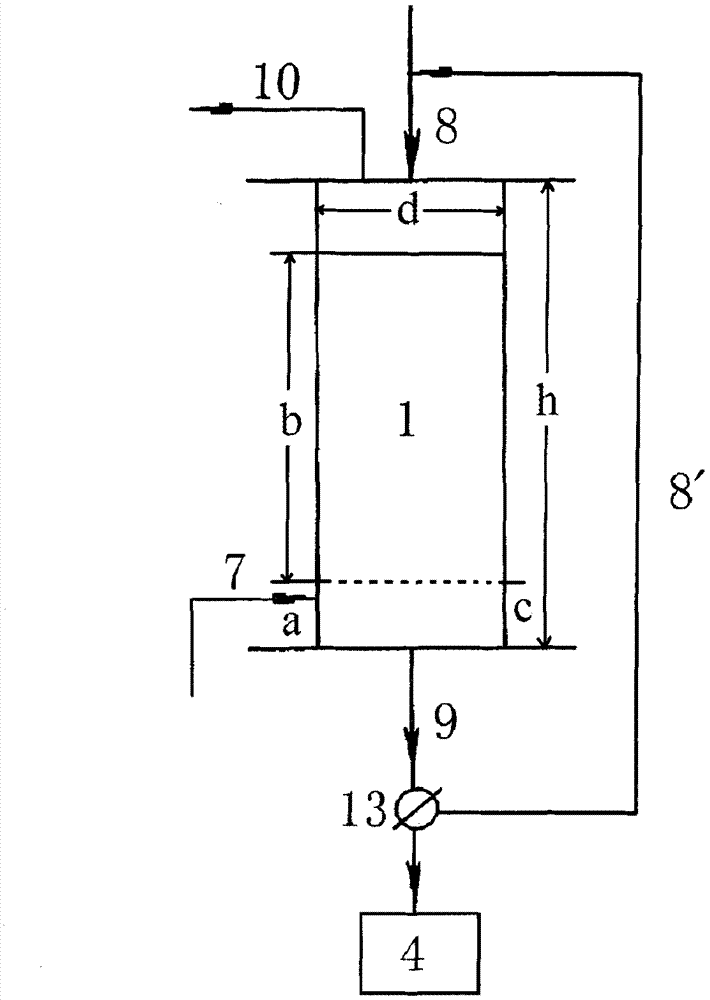

[0129] In this example, using figure 2 Production equipment shown. Specifically, the tower body height h of the reaction tower 1 is 1000mm, the tower inner diameter d is 300mm, the filler (Pall ring) height b is 500mm, and the height c between the lower surface of the filler and the upper surface of the tower bottom flange is 200mm.

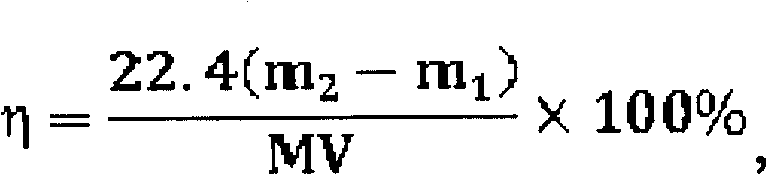

[0130] Use monosilane (i.e. silicon compound, temperature 100°C) as silicon raw material gas 7 at 20m 3 The delivery flow rate of / h is transported into the reaction tower 1 from the lower side of the reaction tower 1 at a height a of 150 mm from the upper surface of the bottom flange of the reaction tower 1 . The temperature in the reaction tower 1 is controlled at about 1600° C., and the atmospheric pressure is controlled at 1 bar. At the same time, molten elemental silicon (purity: 7N) at a temperature of 1600° C. is transported into the reaction tower 1 from the center of the top of the reaction tower 1 as a silicon raw material liquid 8 a...

Embodiment 2

[0135] Exactly the same manner as in Example 1 was carried out except for the following.

[0136] Use the mixed gas of trichlorosilane (i.e. silicon compound) and hydrogen (the volume ratio of trichlorosilane and hydrogen is 1:4) as silicon raw material gas 7, the temperature is 200°C, and the delivery flow rate is 75m 3 / h.

[0137] The temperature in the reaction tower 1 is controlled at about 1800° C., and the atmospheric pressure is controlled at 1 bar.

[0138] The temperature of the silicon raw material liquid 8 is 1900° C., and the delivery flow rate is 160 kg / h.

[0139] The production was stopped after 100 hours of continuous production, a total of 100 kg of silicon raw material liquid 8 was consumed, and a total of about 1400 kg of single crystal silicon (purity 6N) was drawn. As a result, the total power consumption of the production equipment (including the monocrystalline silicon pulling furnace) is about 1.8×10 5 kWh (that is, the average power consumption of ...

Embodiment 3

[0142] Exactly the same manner as in Example 1 was carried out except for the following.

[0143] A mixture of gaseous silicon tetrachloride (i.e. silicon compound) and hydrogen (the volume ratio of gaseous silicon tetrachloride and hydrogen at 400°C is 1:4) is used as silicon raw material gas 7, the temperature is 400°C, and the delivery flow rate is 75m 3 / h.

[0144] The temperature in the reaction tower 1 is controlled at about 1800° C., and the atmospheric pressure is controlled at 2 bar.

[0145] The temperature of the silicon raw material liquid 8 is 1900° C., and the delivery flow rate is 180 kg / h.

[0146] The monocrystalline silicon drawing furnace 4 was changed to a polysilicon ingot furnace (JJL500 polysilicon ingot furnace, rated power 175kW, manufactured by Zhejiang Jinggong Technology Co., Ltd., not shown) to manufacture polysilicon ingots.

[0147] The production was stopped after 100 hours of continuous production, a total of 150 kg of silicon raw material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com