Folding mandrel, device and method for manufacturing glued sleeves

A folding core and bonding technology is applied in the field of folding mandrels of devices and devices for processing bonding sleeves, which can solve problems such as contamination and achieve the effect of avoiding operation interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

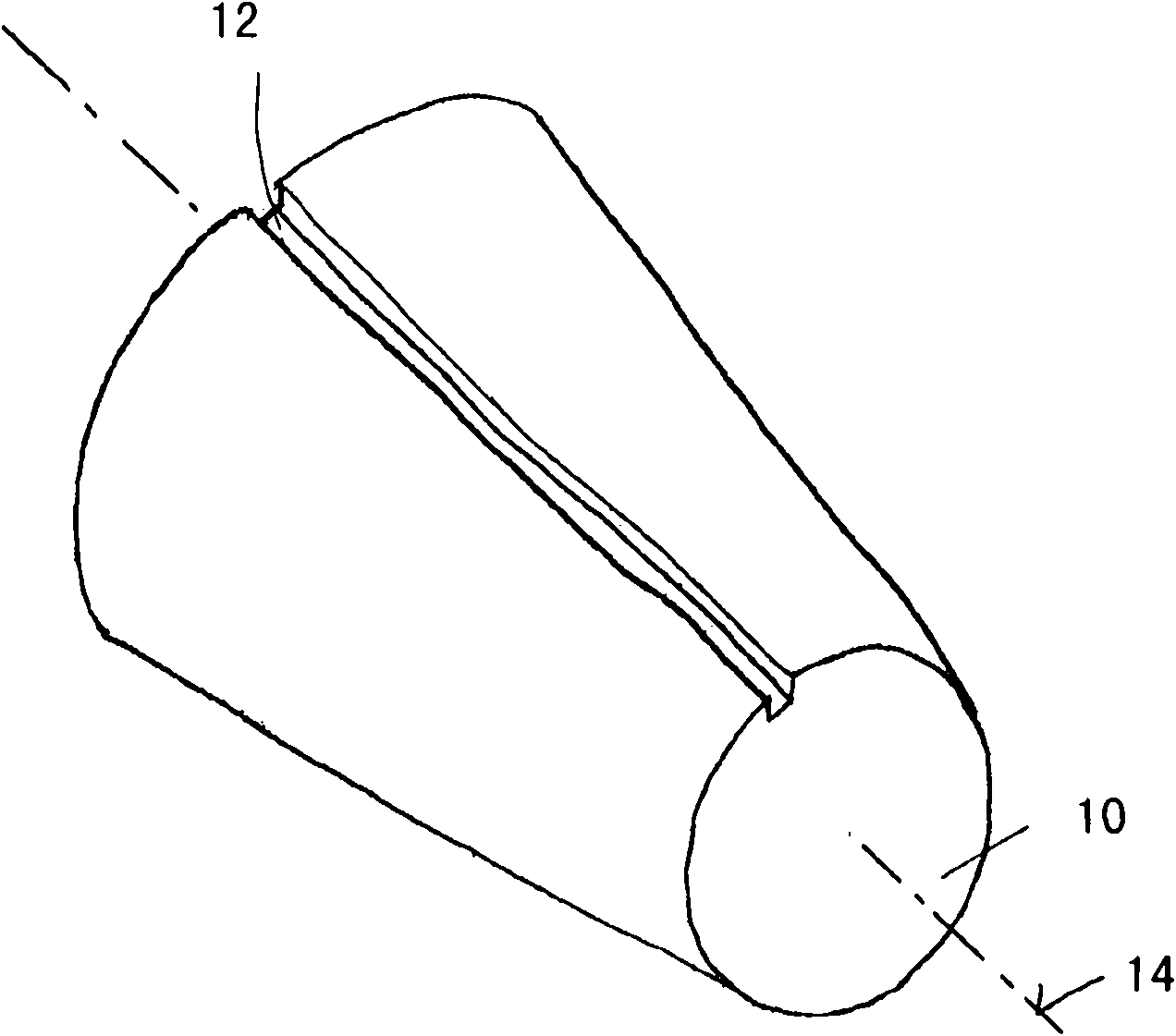

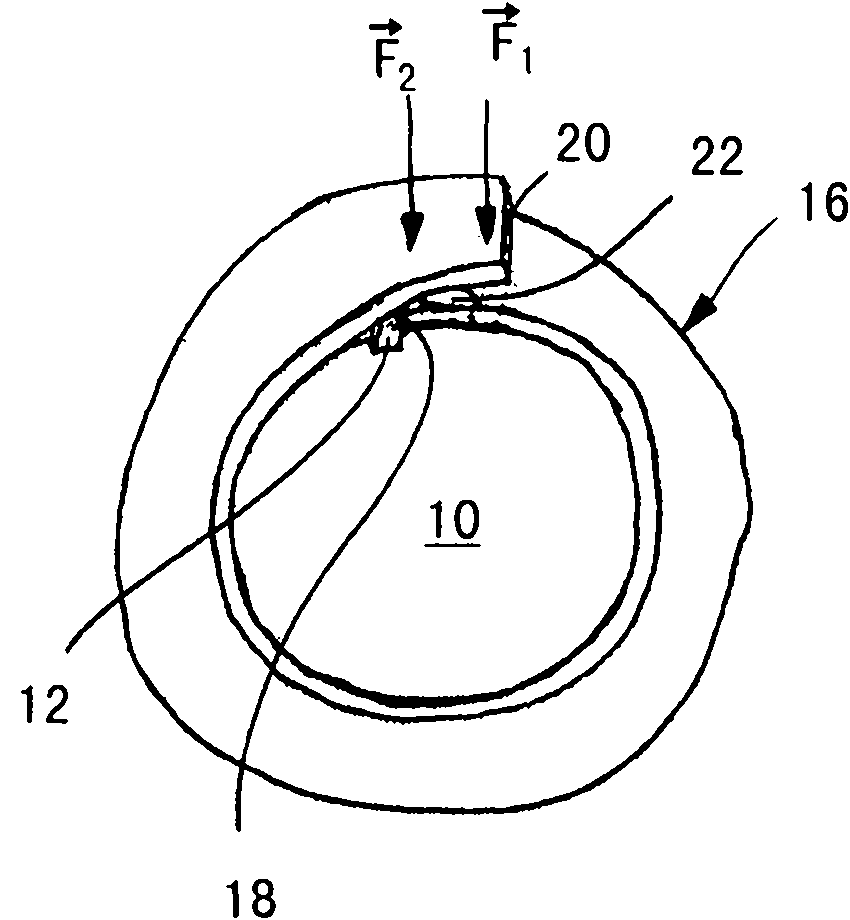

[0029] figure 1 The view of shows a folding mandrel 10 according to the invention, which has the shape of a truncated cone and around which a paper sector can be wound, as in image 3 as shown in Unwind Status. In this case, the paper segments are dimensioned in such a way that after winding there is an overlap, so that the paper segments can be bonded in the area of the overlap in order to thereby obtain a frustoconical sleeve. These frusto-conical sleeves can then be provided with a bottom for serving as an inner cup for the beverage. These frusto-conical sleeves can also be inserted over the inner cup to form an insulating shell if a double-walled cup for hot beverages is to be manufactured.

[0030] The folding mandrel 10 is provided with a groove 12 which has a rectangular cross section and extends from the conical outer surface of the folding mandrel 10 inwards in the direction of the center axis 14 of the folding mandrel 10 . The groove 12 extends parallel to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com