Processing technology of steam turbine seven-fork blade root pin holes and special fixture

A processing technology and steam turbine technology, which is applied to the supporting elements of blades, manufacturing tools, metal processing equipment, etc., can solve the problems of affecting product quality, difficult to ensure the accuracy of the position of the processed holes, letting the knife, breaking and other problems, so as to improve the production efficiency. and product quality, ensure accuracy and roughness, and ensure the effect of assembly requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

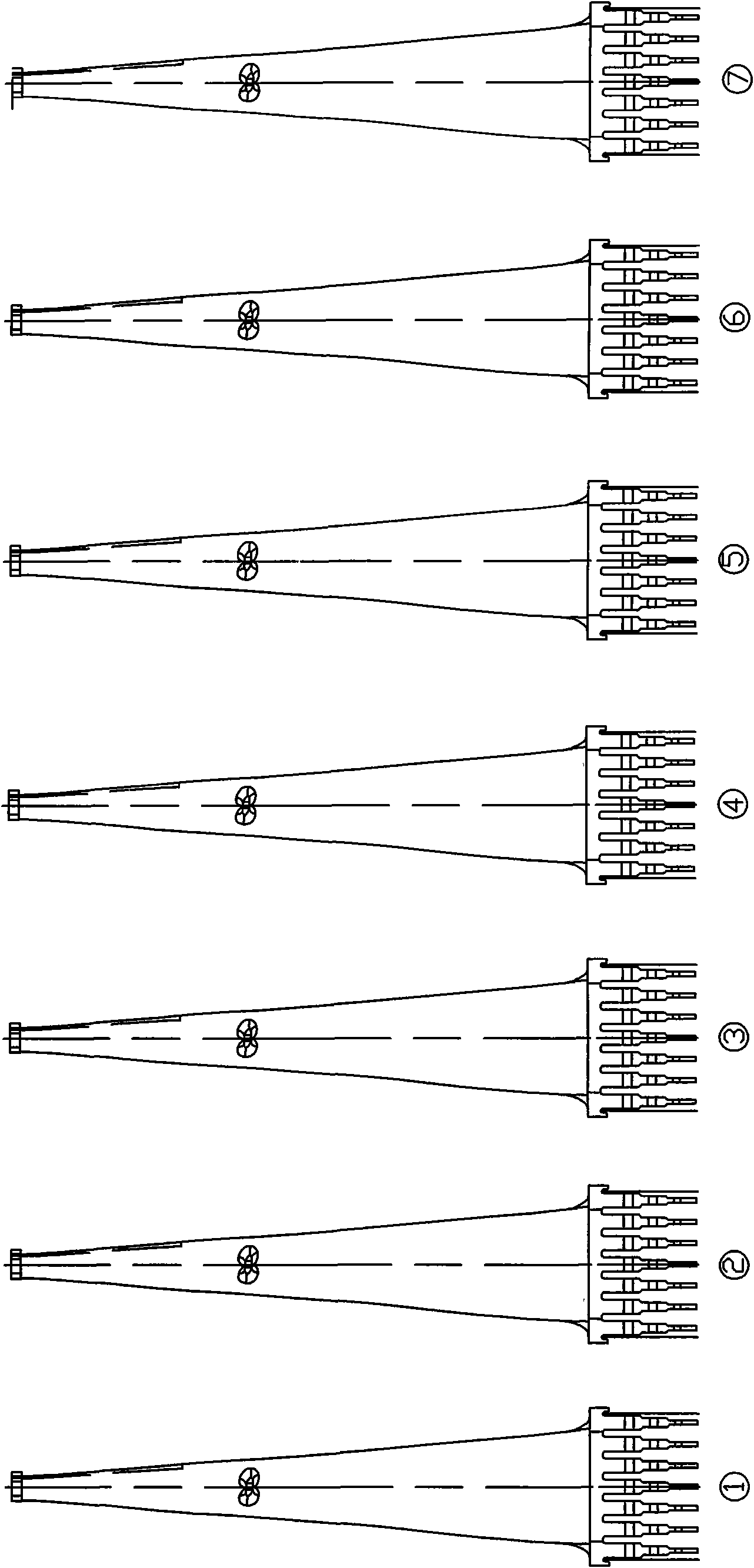

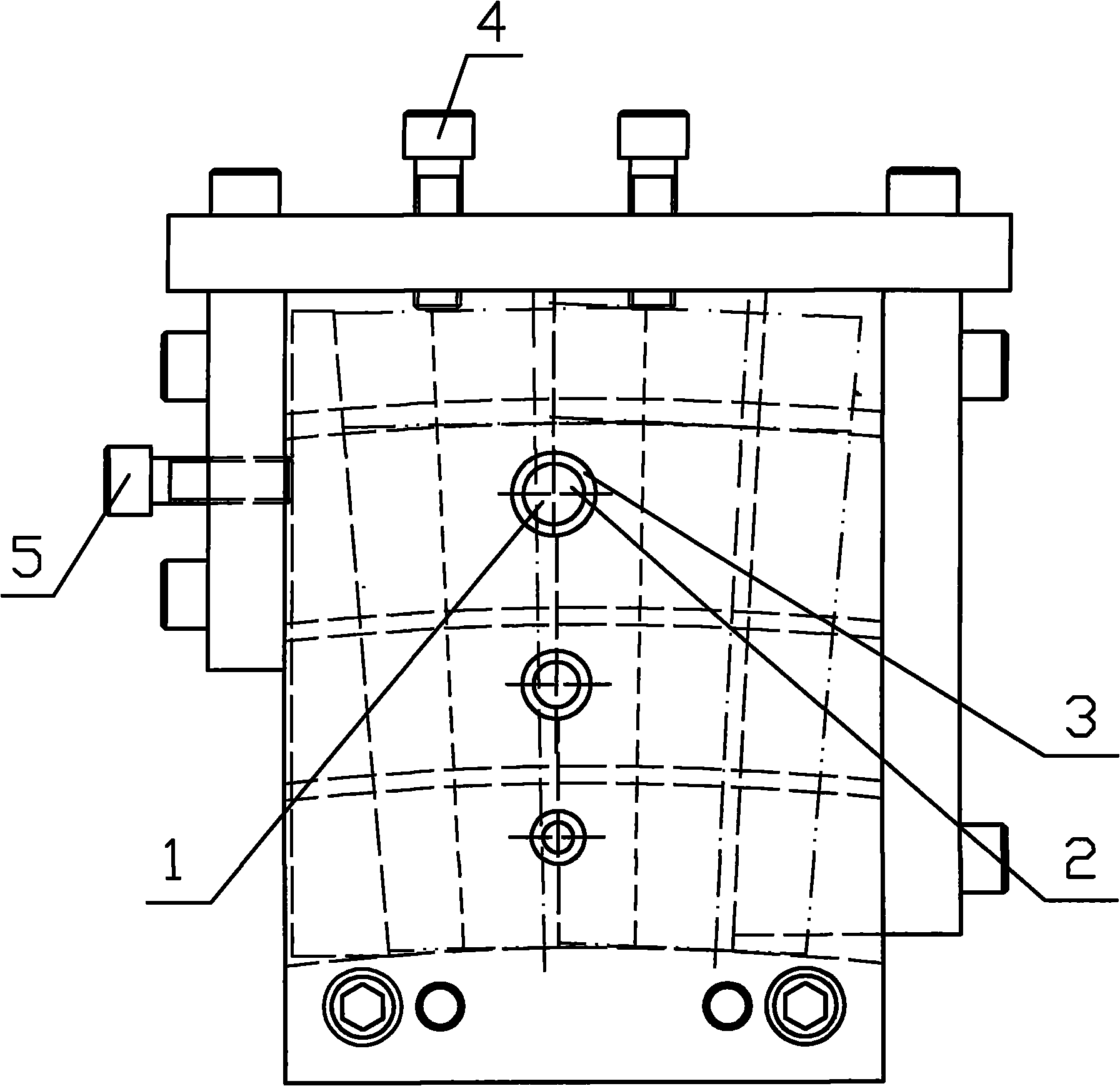

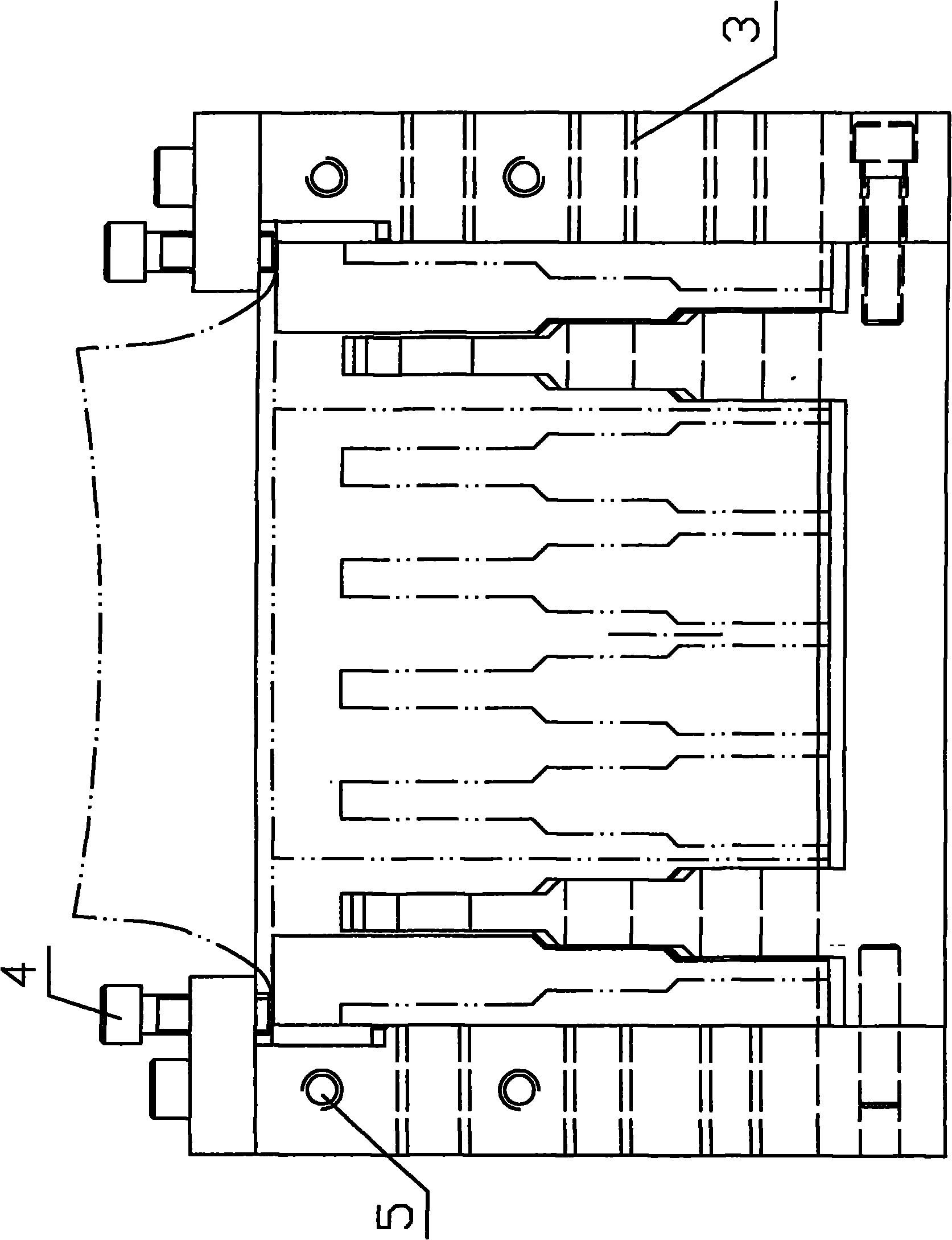

[0023] A jig for processing the pin holes of the root of a seven-prong blade of a steam turbine. The root of the blade has seven forks for installation. The outer two forks of the seven forks are set in a staggered manner from the inner five forks. Three pin holes are arranged in sequence in the direction of the line, and three first semicircular pin holes 1 coaxial with the aforementioned three pin holes are sequentially arranged on the outer two forks, and three first semicircular pin holes 1 coaxial with the aforementioned three pin holes are arranged on the outer two forks. The other three second semicircle pin holes 2 on the coaxial line of the five-prong upper pin holes, the first semicircle pin holes 1 and the second semicircle pin holes 2 on the outer two forks of the adjacent two seven-prong blades are combined to form a full circle pin Holes, the blades are arranged radially and circumferentially on the steam turbine. It is characterized in that: the fixture has a cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com