High efficiency maintenance-free storage tank cabin top dust collection device

A dust collection device and maintenance-free technology, which is applied in the direction of transportation and packaging, conveying bulk materials, conveyors, etc., can solve problems such as difficult maintenance, frequent replacement of cloth bags, and inability to guarantee dilute phase transportation of alumina materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

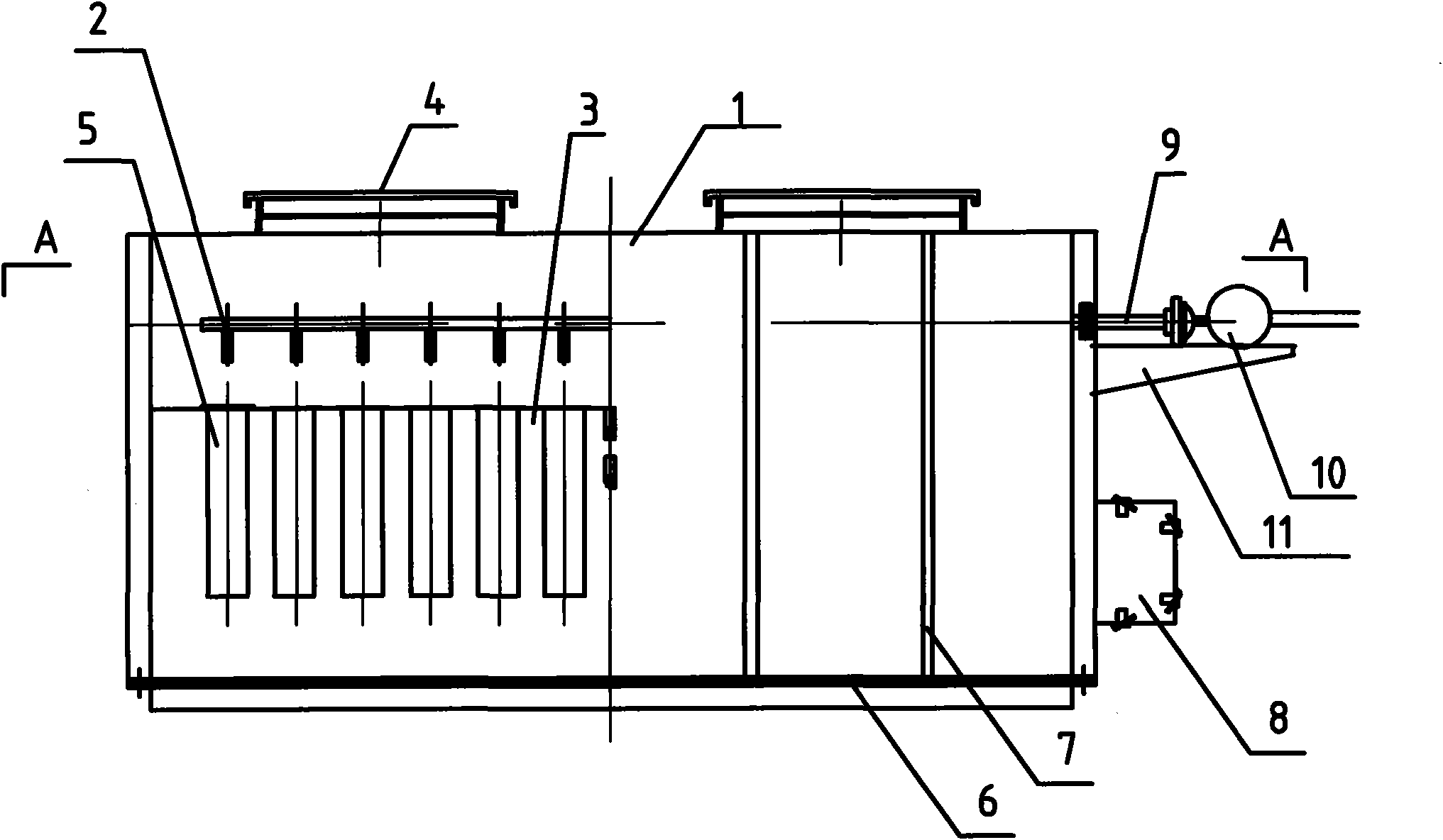

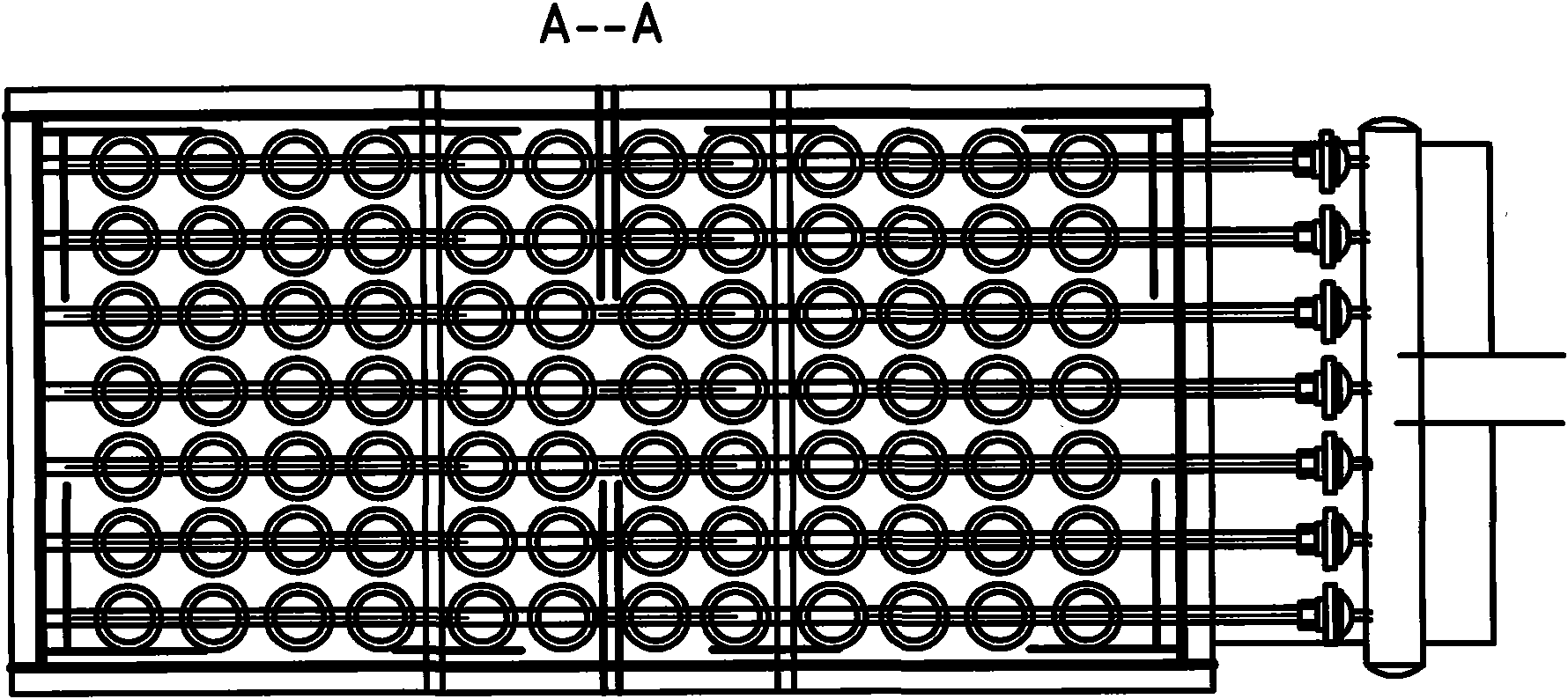

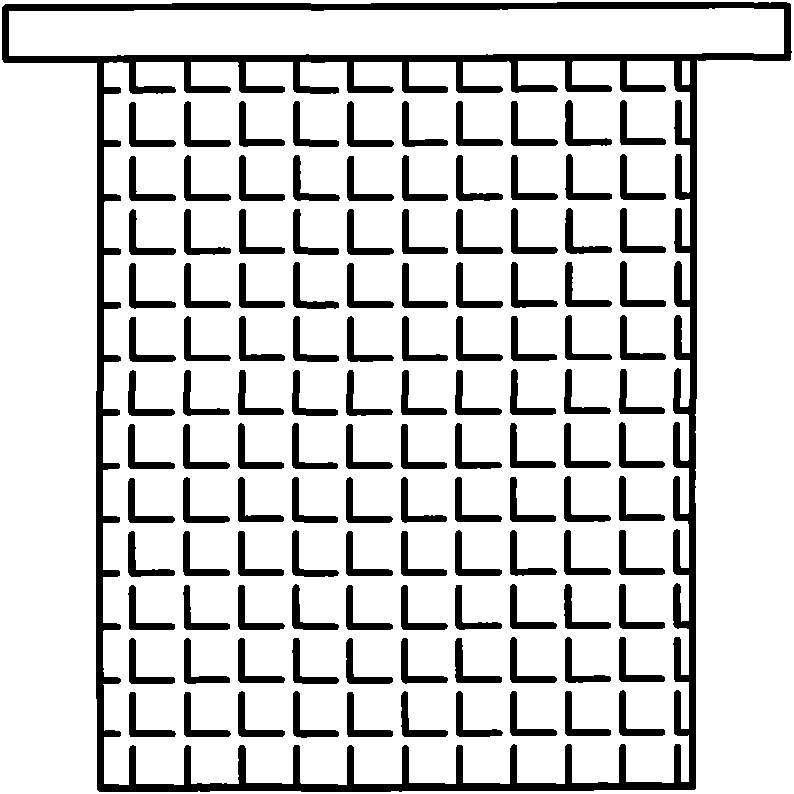

[0009] like figure 1 , figure 2 As shown, the present invention is composed of an air source device and a dust collecting box. The box 1 of the dust collector is a pressure-resistant box, welded with steel plates, and its surface is reinforced with iron bars 7 to ensure that it can withstand 6kg / cm 2 pressure. The upper part of the box body 1 is provided with an air outlet 4 that communicates with the atmosphere, and the lower structure matches the air outlet on the top of the alumina storage tank, with an area of 8m 2 , and is provided with an angle steel flange 6 for fixing; the air source device is composed of several pulse valves 9 and an air source distributor 10, which are installed on one side of the upper part of the box through a support frame 11; one end of the air source distributor 10 is connected to the compressor. The air pipelines are connected, and the other end is connected to the pulse valve 9; the pulse valve 9 sends gas to several nozzles 2 in the dus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com