Electromagnetic converter

A transducer and electromagnetic technology, applied in the direction of sensors, electrical components, planar diaphragms, etc., can solve the problems of low regenerative sound pressure level, reduced magnetic flux density, and inability to expand the interval of permanent magnets, etc., to achieve low volume with large volume Sound field reproduction, large-amplitude effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

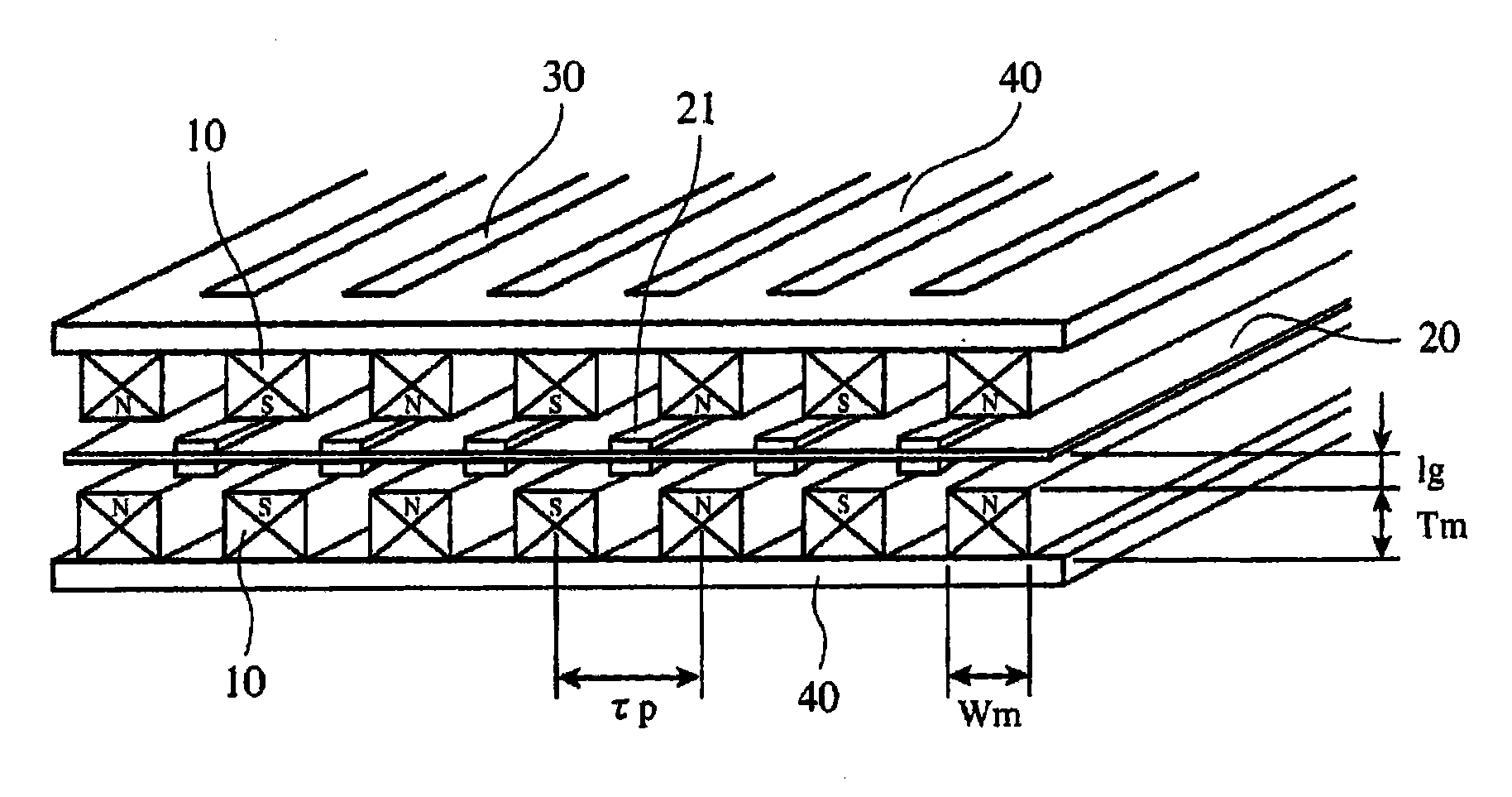

[0016] figure 1 It is a perspective view showing the configuration of the electromagnetic transducer according to Embodiment 1 of the present invention.

[0017] In the figure, the electromagnetic transducer has: a first magnet alignment layer, which alternately makes different magnetic poles face each other on a plane, and arranges a plurality of rods with a width Wm, a thickness Tm, and a predetermined length in parallel at intervals of a fixed magnetic pole pitch τp. permanent magnet 10. In addition, the electromagnetic transducer is provided with: a second magnet layer, which is formed to have the same arrangement of rod-shaped permanent magnets 10 as the first magnet arrangement layer, and has the same magnetic poles facing each other in the vertical direction with the first magnet arrangement layer, and faces each other. The magnet surfaces are separated by a distance of 2×lg. The rod-shaped permanent magnets 10 of the first and second magnet array layers are fixed to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com