Rotary type electric connection device and socket thereof

An electrical connection device, a rotary technology, applied in the direction of the two-part connection device, the parts of the connection device, the connection, etc., can solve the problems of accidental rotation of the plug, troublesome operation, poor reliability of the electrical connection device, etc., to avoid major disasters. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The rotary electrical connection device and its electrical connection method of the present invention will be described below with a preferred embodiment of a socket and a plug.

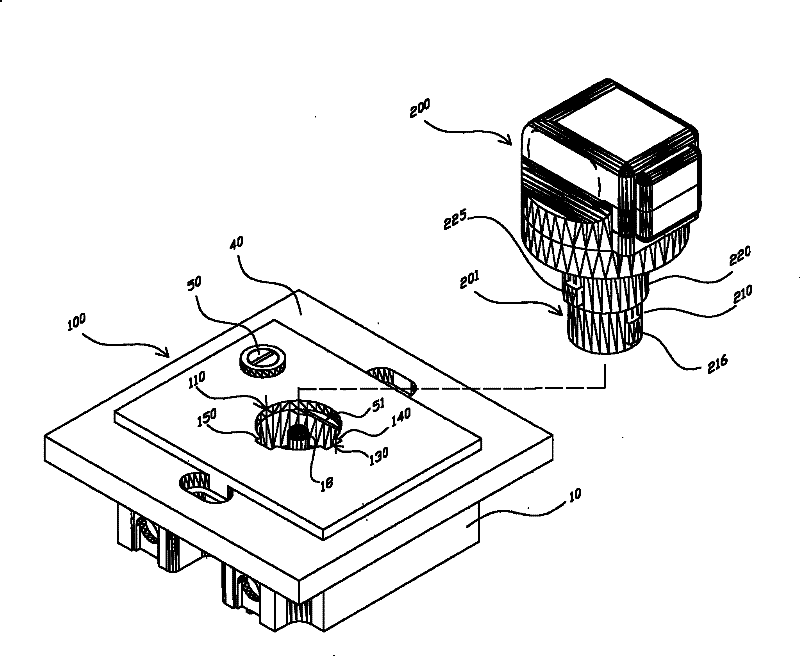

[0033] Such as figure 1 As shown, the electrical connection device of the present invention includes a socket 100 and a plug 200 .

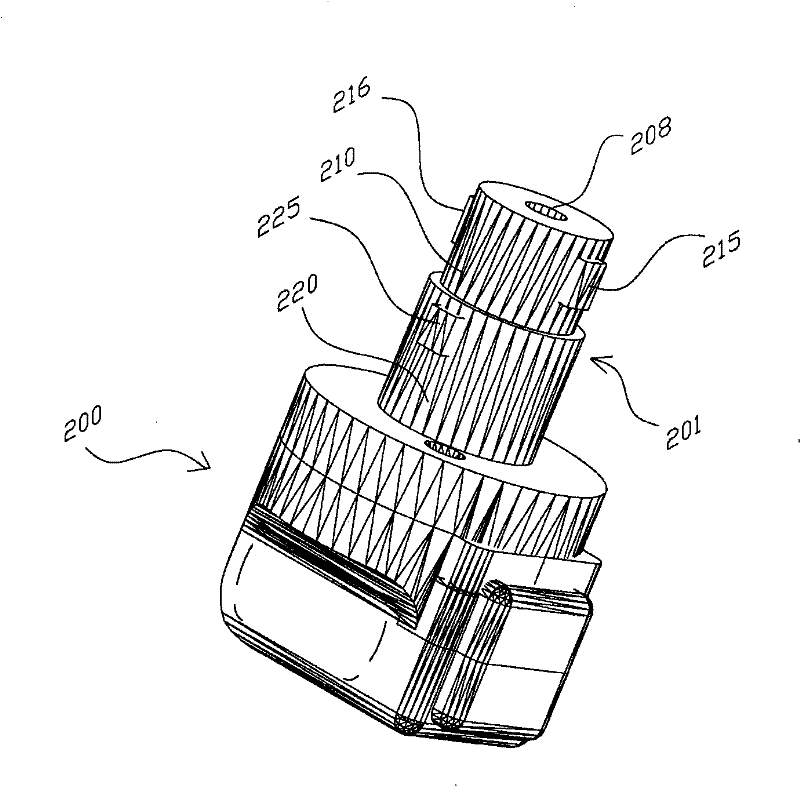

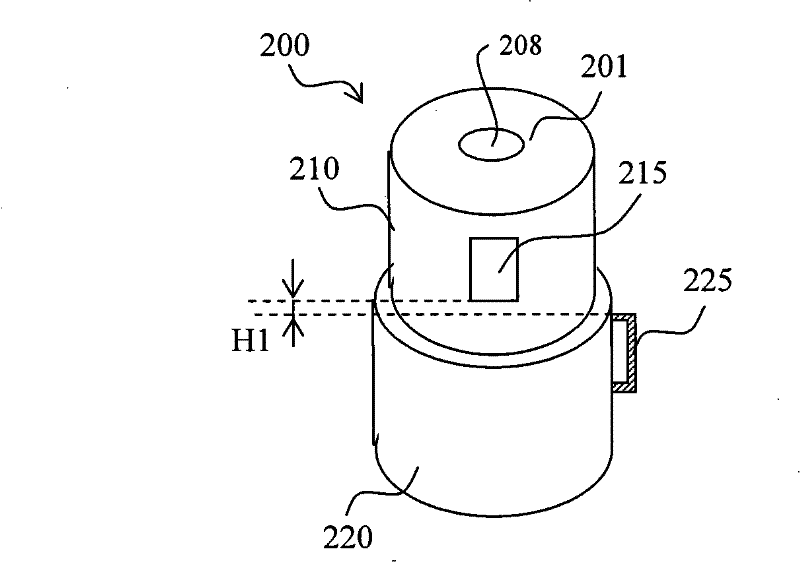

[0034] combine Figure 2A , 2B As shown, the plug 200 has a cylindrical socket plug 201 , two first power supply electrodes 215 , 216 opposite to each other and a first ground electrode 225 are provided on the outer wall thereof for conductive connection. Preferably, in order to facilitate plugging and unplugging, the plug 200 of the present invention is formed into a stepped shape, that is, it is formed by connecting a first cylinder 210 and a second cylinder 220, and the outer diameter of the first cylinder 210 is smaller than that of the second cylinder 220 outside diameter.

[0035] In order to avoid electric sparks or arcing during electrical contact, in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com