Low-frequency vibration isolator with three degrees of freedom

A degree of freedom and vibration isolator technology, applied in gas shock absorbers, springs/shock absorbers, springs, etc., to achieve good low-frequency vibration isolation and good vibration isolation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The structure, principle and working process of the present invention will be further described below in conjunction with the accompanying drawings.

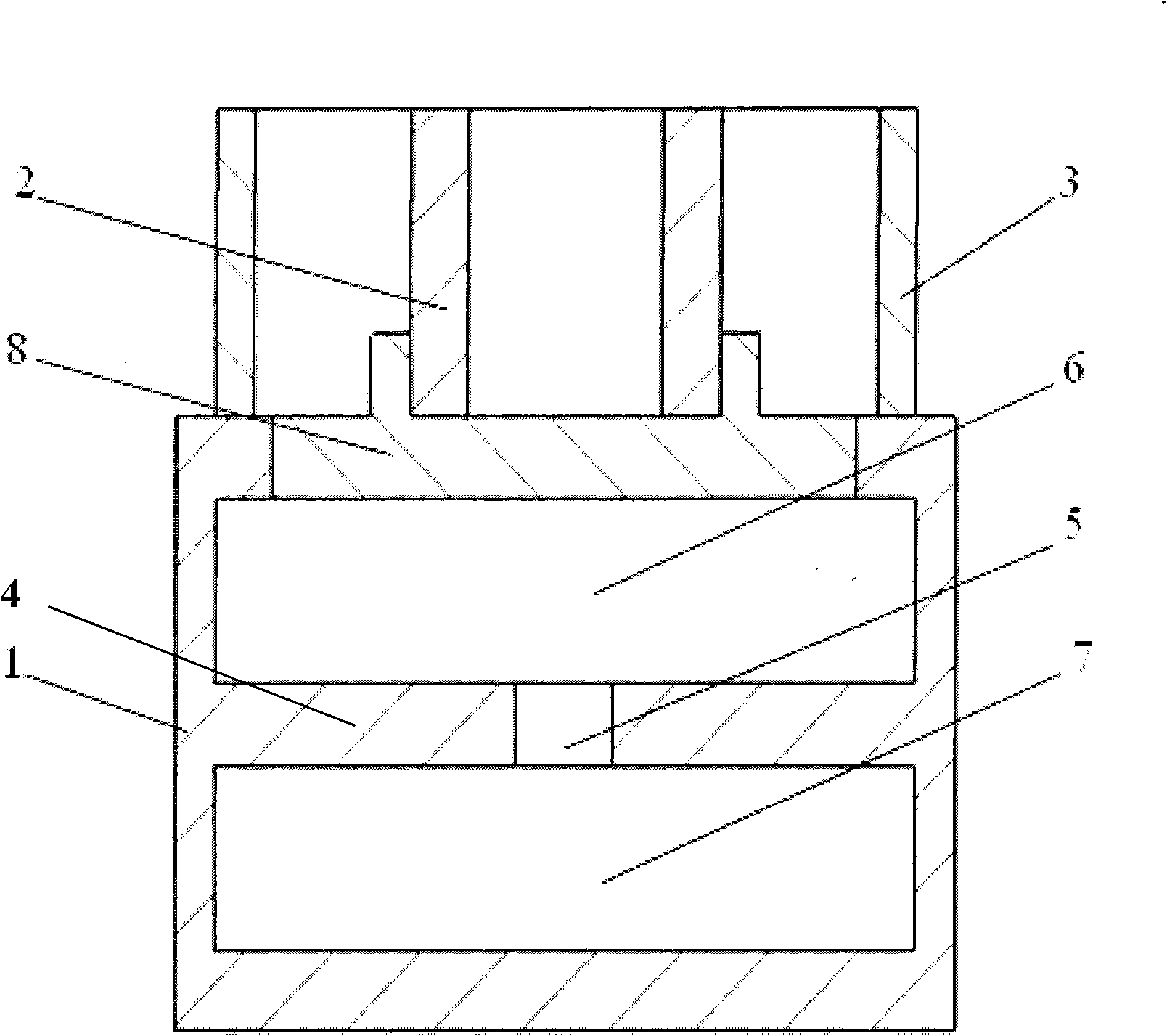

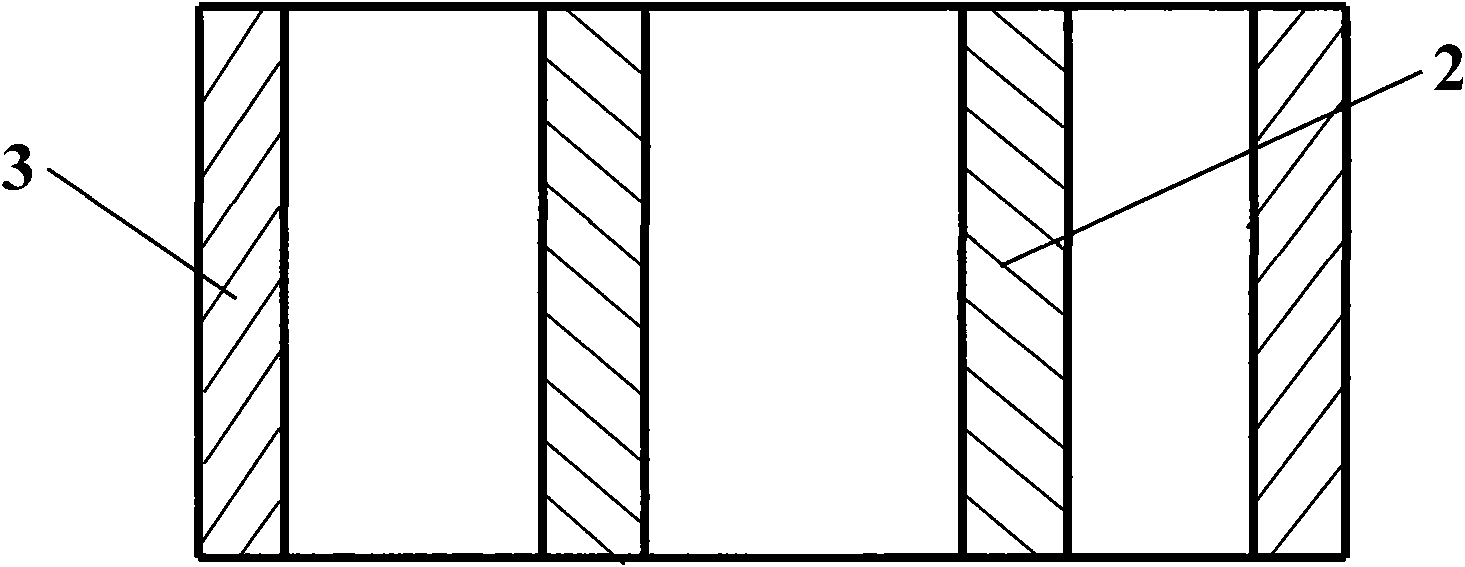

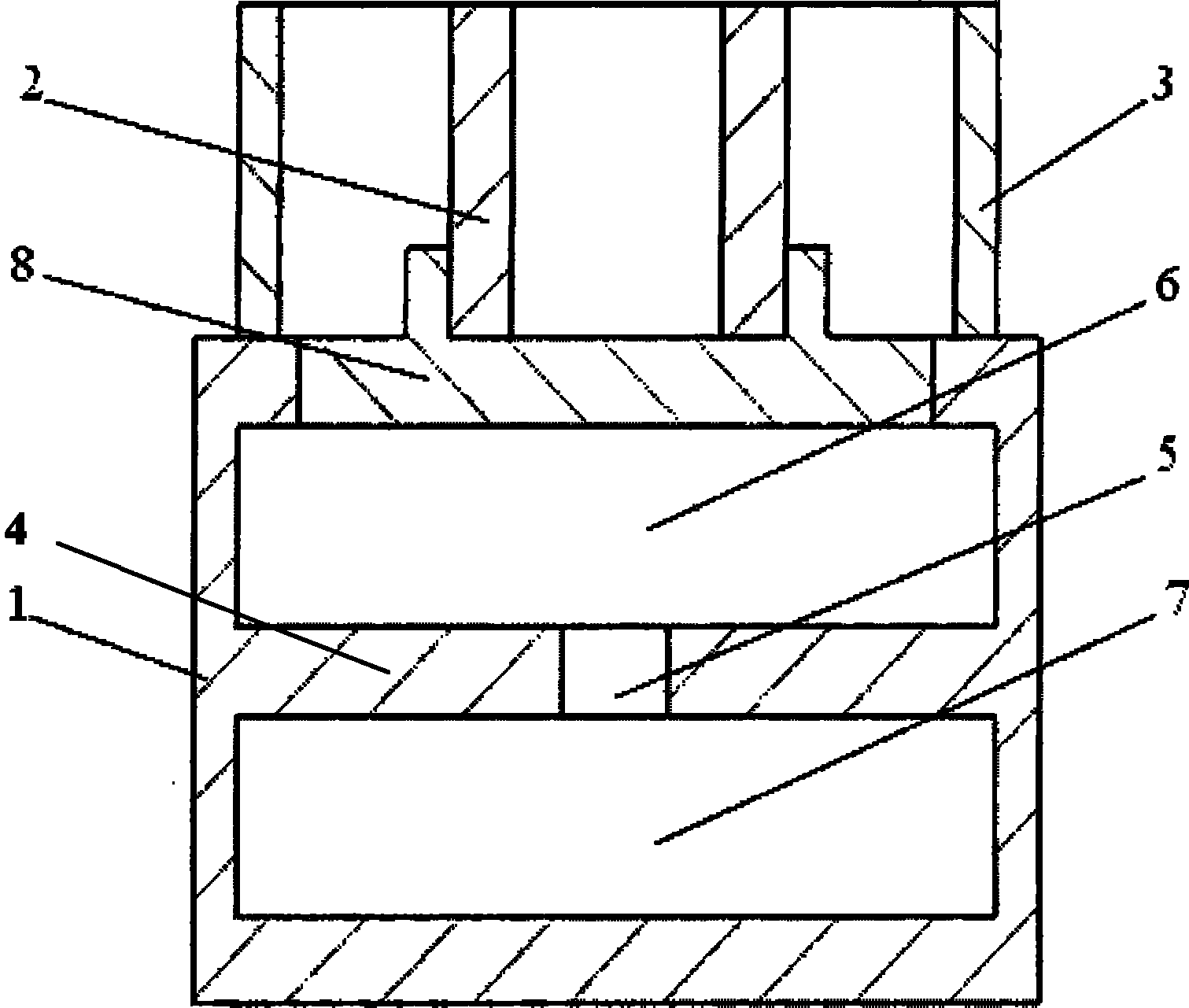

[0017] figure 1 Provide the present invention with a schematic diagram of the structural principle (main sectional view) of a low-frequency three-degree-of-freedom vibration isolator, which includes an air spring, an inner hollow cylindrical permanent magnet 2 and an outer hollow cylindrical permanent magnet 3, and the air spring Including an air spring main body 1 and a rubber piston 8, the air spring main body consists of an upper chamber 6, a lower chamber 7 and an orifice 5 communicating with the upper and lower chambers; the inner hollow cylindrical permanent magnet and the outer hollow cylindrical permanent magnet are the same The shaft is arranged, the outer hollow cylindrical permanent magnet is fixed on the top of the air spring main body, the inner hollow cylindrical permanent magnet is fixed on the rubber pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com