Vacuum oil tubing coupling

A oil pipe and vacuum technology, which is applied in the direction of drill pipe, casing, drilling equipment, etc., can solve the problems of large heat transfer temperature difference, large heat loss, large specific weight, etc., to achieve enhanced thermal insulation performance, enhanced sealing performance, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

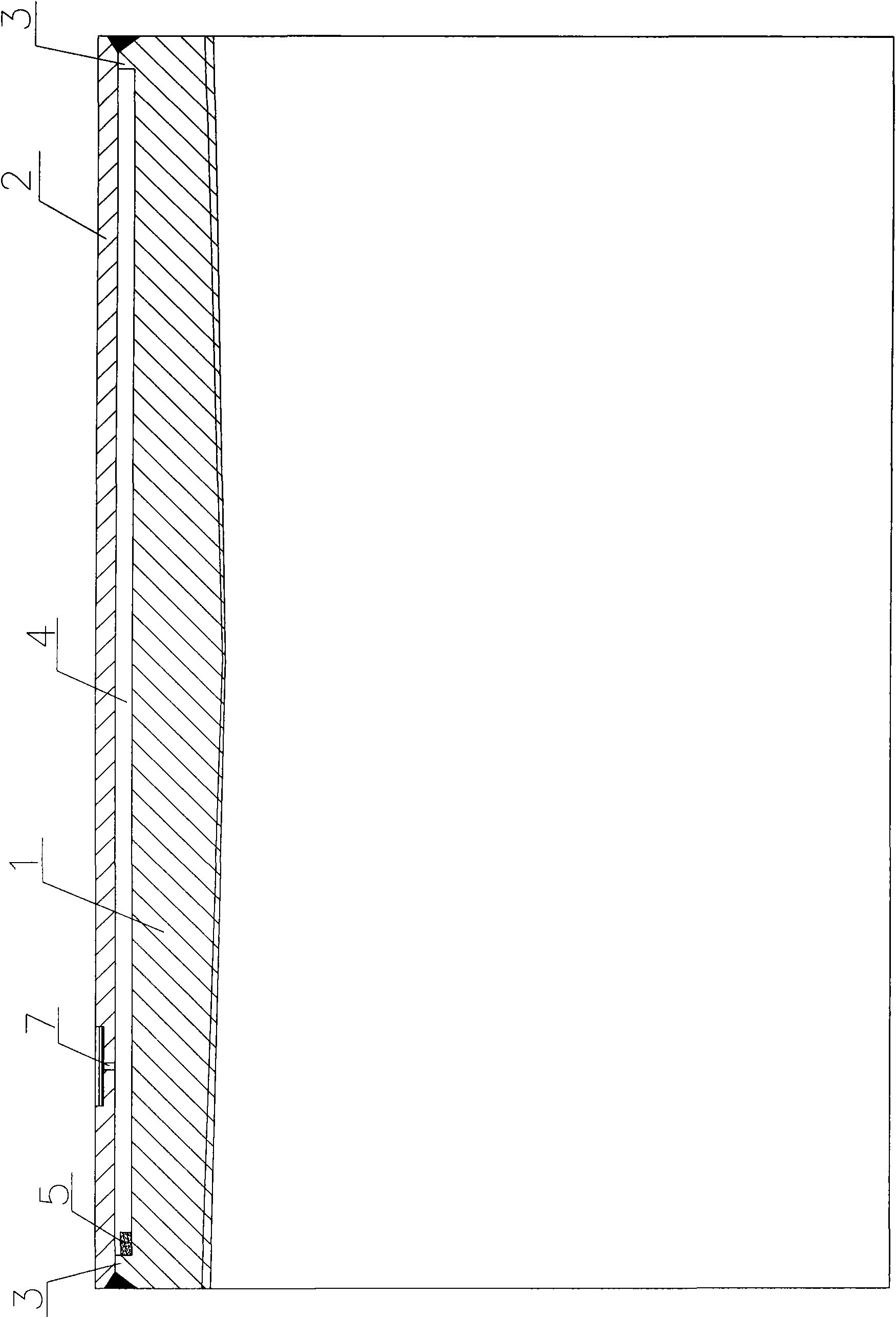

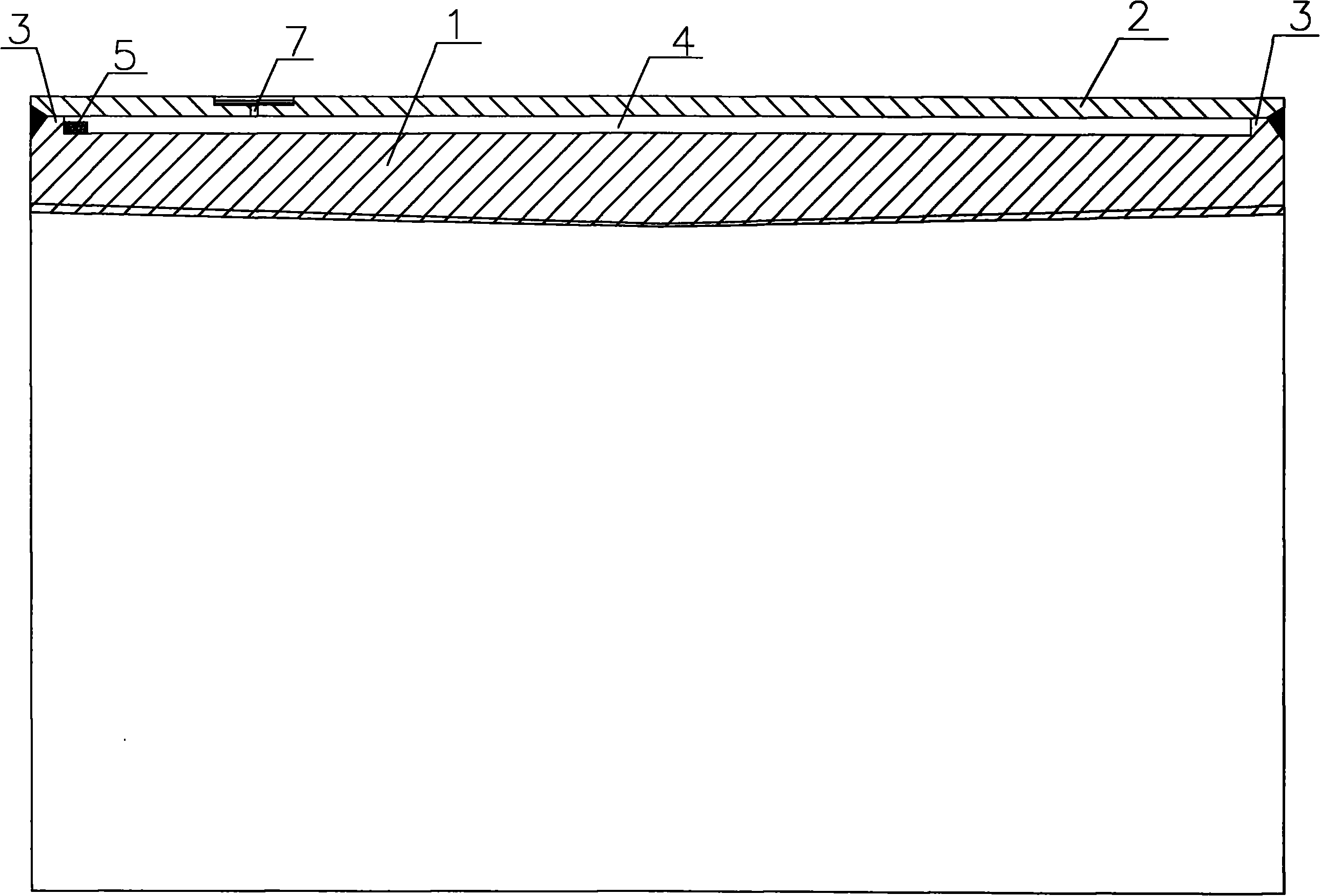

[0020] Example 1, such as figure 1 As shown, the present invention includes a coupling body 1 and an outer jacket 2. The coupling body 1 is cylindrical, and the two ends of the inner surface of the coupling body 1 are provided with tapered holes that are large on the outside and small on the inside, and the inner surface of the taper hole is provided with threads. The threaded taper hole is used to connect two thick oil steam injection tubing or downhole tubing for oil production, and makes the joint of the two tubing have good sealing performance and thermal insulation performance. A closed vacuum layer 4 is provided between the outer surface of the hoop body 1 and the inner surface of the jacket 2 . The closed vacuum layer 4 is surrounded by the inner surface of the jacket 2, the outer surface of the coupling body 1, and the flanges 3 at the edges of the outer surface at both ends of the coupling body 1, and the flanges 3 are respectively connected to the inner surface of th...

Embodiment 2

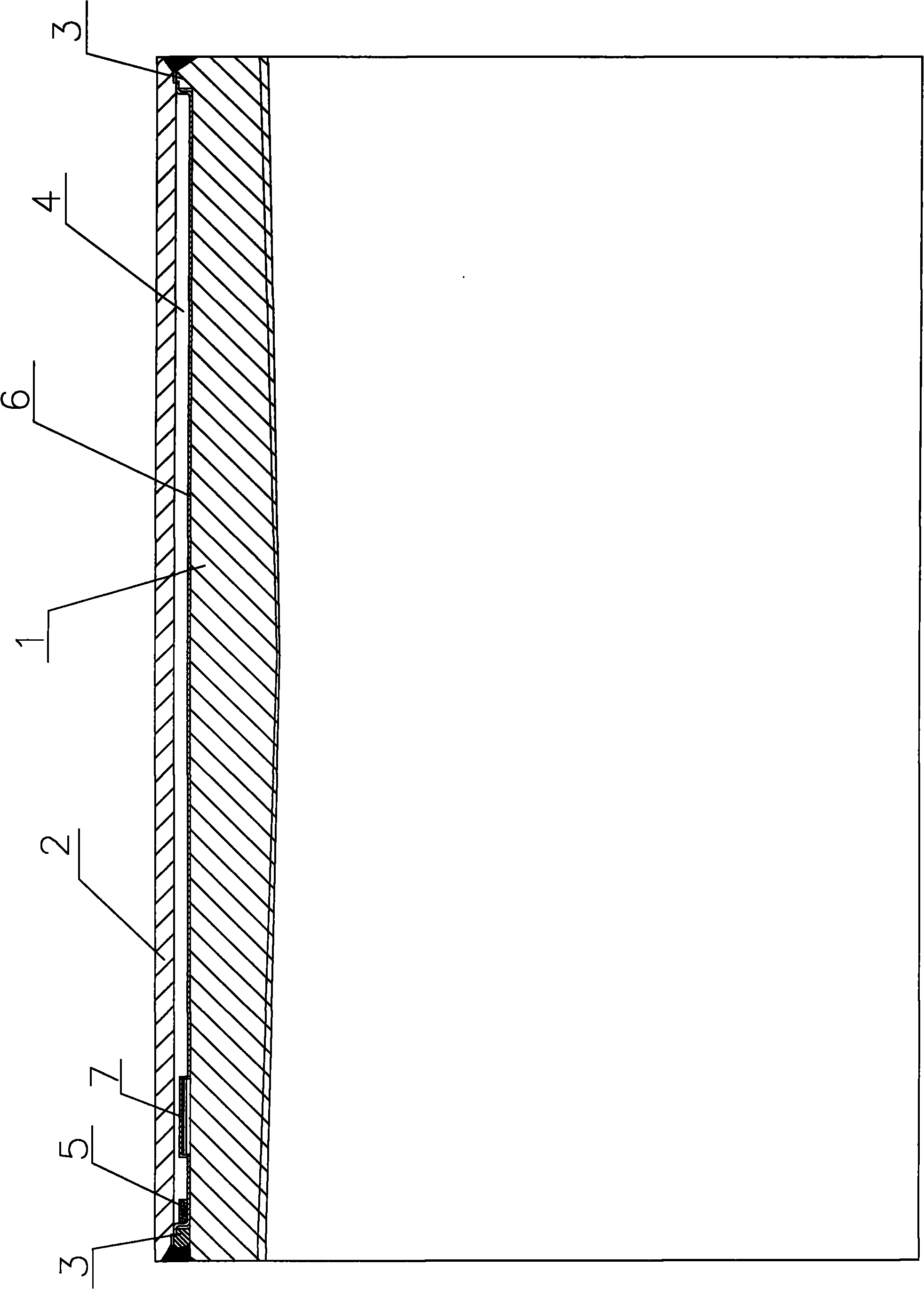

[0022] Example 2, such as figure 2 As shown, there is a heat insulating sleeve 6 between the outer surface of the coupling body 1 and the inner surface of the jacket 2. Said closed vacuum layer 4 is formed between the surfaces. The heat insulating sleeve 6 is provided with a vacuum hole 7 along its radial direction. After the air in the closed vacuum layer 4 is vacuumed through the vacuum hole 7, the vacuum hole 7 is also sealed by silver-copper brazing. Other features in this embodiment are the same as Embodiment 1.

[0023] In the above technical solution, the thickness of the stainless steel layer 6 ranges from 0.3 to 0.8 mm, preferably 0.5 mm.

[0024] In Embodiment 1, during processing, the coupling body 1 is sleeved on the jacket 2 to extract the air in the sealed vacuum layer 4 through the vacuum hole 7 .

[0025] In embodiment 2, during processing, the air in the sealed vacuum layer 4 is drawn through the vacuum hole 7 of the heat insulating sleeve 6 first, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com