Drying and corrosion prevention method and system of main cable of suspension bridge

A suspension bridge and main cable technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of frequent replacement of dehumidification element runners, increased system cost, high maintenance cost, etc., and achieves simple structure, low energy consumption and easy implementation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

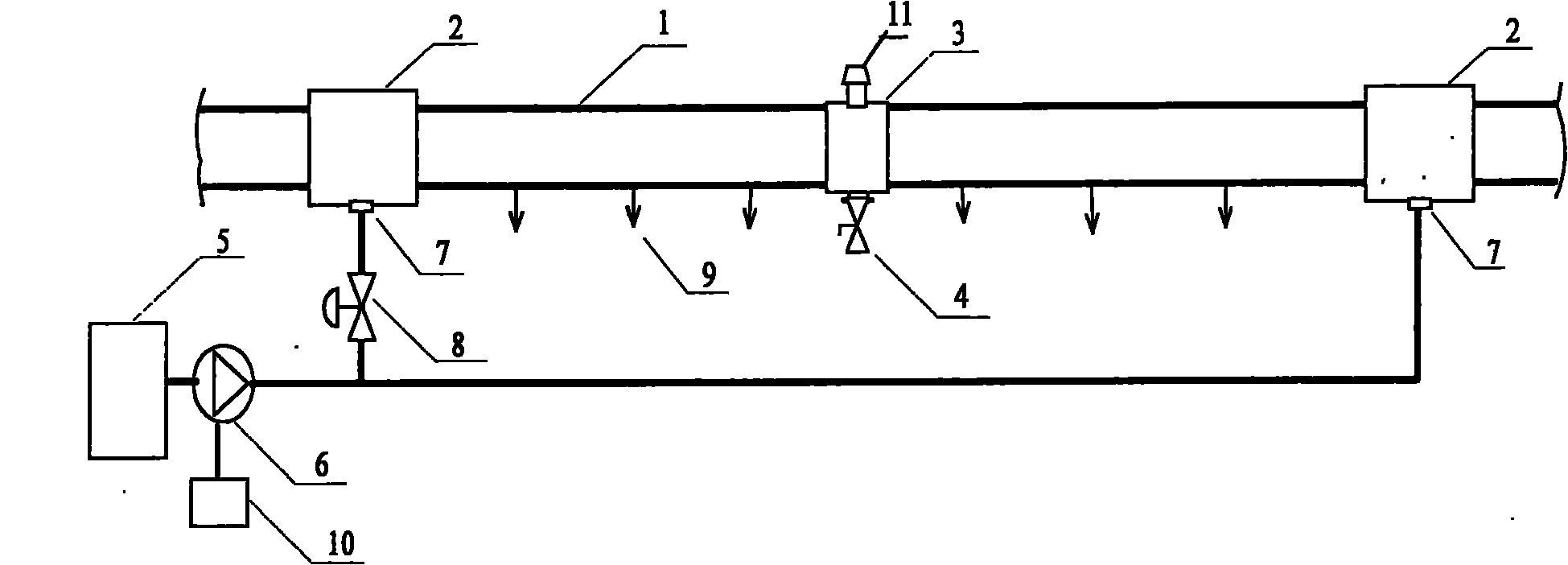

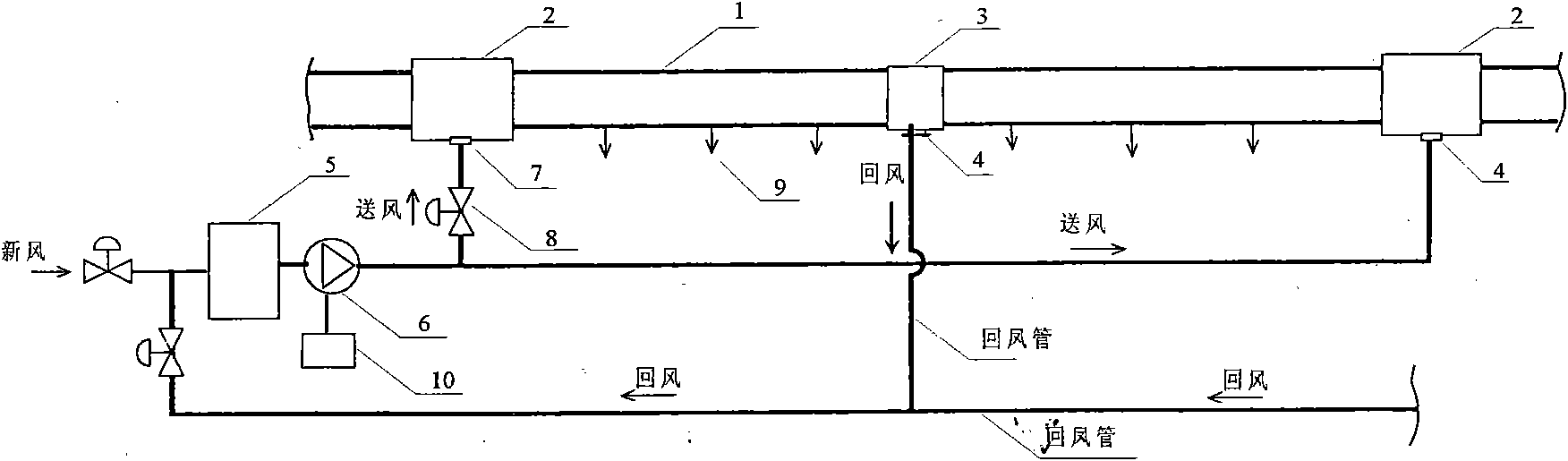

[0013] refer to figure 1 As shown, Embodiment 1 of the present invention: a drying and anticorrosion system for the main cable of a suspension bridge, including between the appropriate gaps in the longitudinal direction where the closed sheath layer is covered on the outer periphery of the main cable 1, and an air intake for dredging the inner side is provided. Cover 2 and exhaust cover 3, an overpressure automatic exhaust valve 11 is installed on the upper part of the exhaust cover 3, and a manual exhaust valve 4 is installed on the lower part of the exhaust cover 3, and the dry air is sent to the main cable by the above-mentioned intake cover 2 The gap of the inner steel wire is then discharged by the overpressure automatic exhaust valve 11 and the manual exhaust valve 4 on the exhaust hood 3. Rotary dehumidifier 5, Roots blower 6, air inlet 7, regulating valve 8, air leakage along the way 9, frequency converter 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com