Basal plate retainer for ECR (Equivalent Continuous Rating) plasma sputtering device

A technology of substrate holder and sputtering device, which is applied in sputtering plating, ion implantation plating, metal material coating process, etc., can solve the problems of affecting the area of deposited film, occupying the cross-sectional area of vacuum chamber, sample size limitation, etc. , to achieve the effects of low cost, increased area, and improved simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

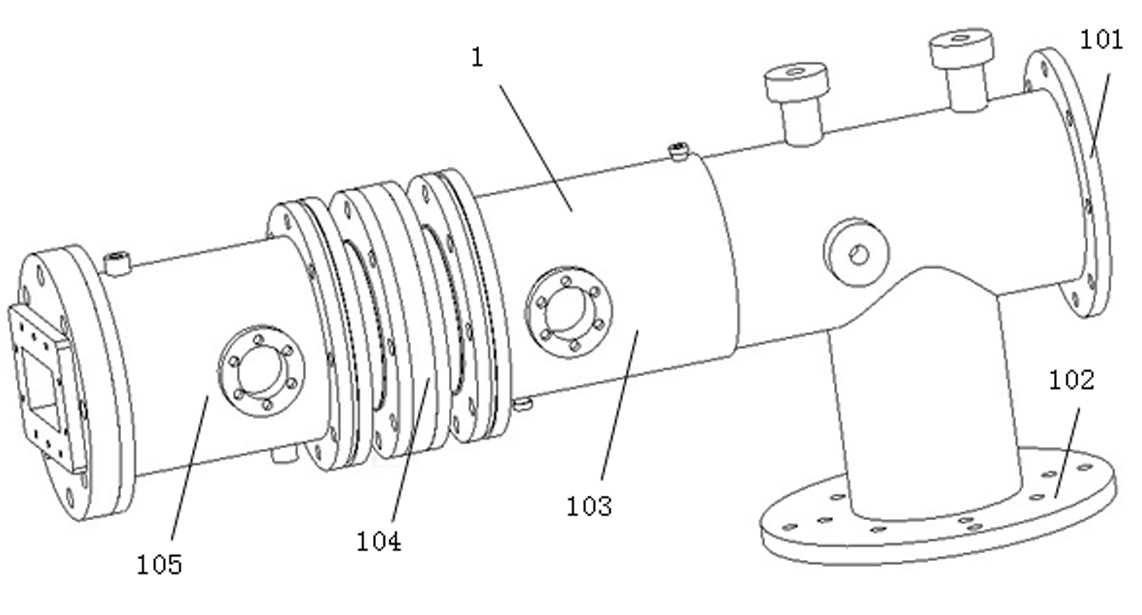

[0018] refer to figure 1 , is the vacuum chamber of the ECR plasma sputtering device, the vacuum chamber 1 includes: a left chamber 105 and a right chamber 103, a target frame 104 is arranged in the middle of the left chamber 105 and the right chamber 103, and the right chamber 103 is axially A cage flange 101 is arranged in the direction, and a molecular pump flange 102 is arranged in the radial direction.

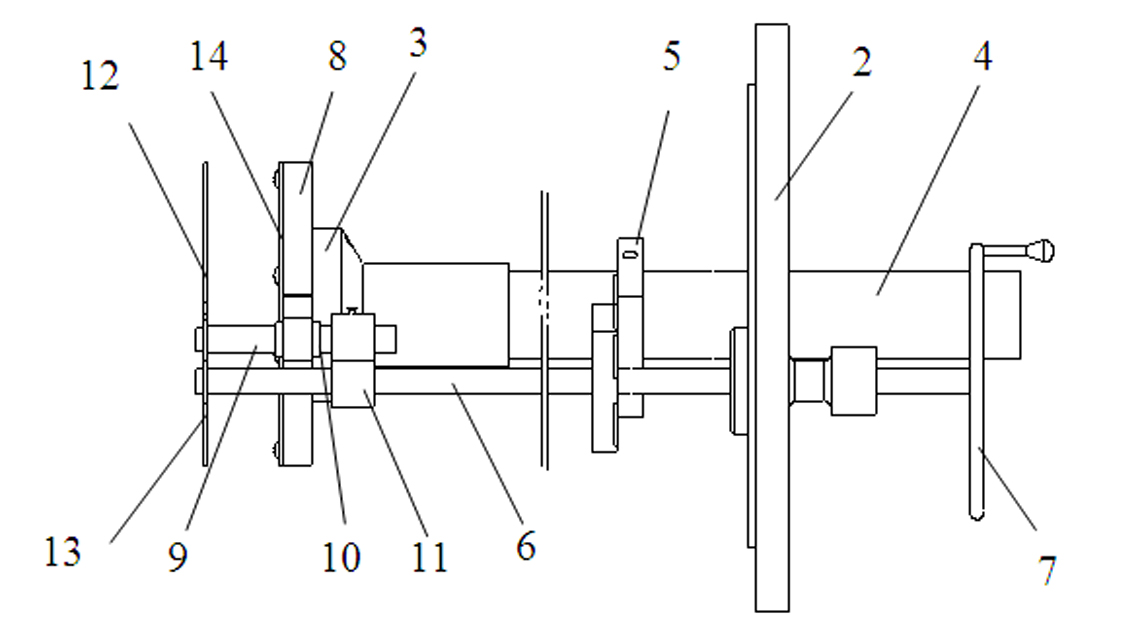

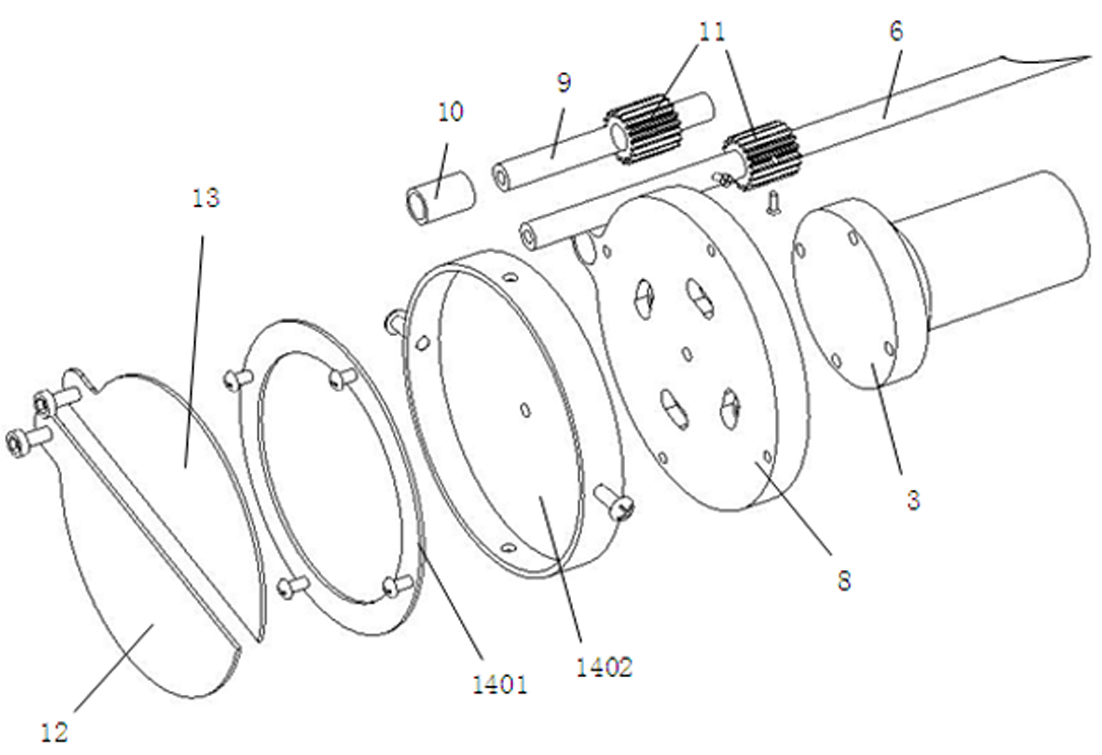

[0019] combine figure 2 , image 3 , the substrate holder protrudes into the interior of the vacuum chamber 1 and is connected with the holder flange 101 provided on the right chamber 103 through the fixing flange 2 . The substrate holder of the present invention includes an original substrate 3, a fixed shaft 4 connected to the original substrate 3, a fixed flange 2 and a support plate 5 are arranged axially on the fixed shaft 4, and the support plate 5 and the fixed flange 2 run through The transmission shaft 6 parallel to the fixed shaft 4 is provided with a rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com