Quick drying hand inkpad for hand model

A technology of hand molds and fingerprints, which is applied in the field of quick-drying hand molds and muds, which can solve the problems of hand molds and muds that are not easy to dry, not beautiful enough, easy to deform, etc., achieve good decoration and commemorative functions, fast drying speed, and easy preservation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Bronze effect hand mold handprint mud and its preparation process

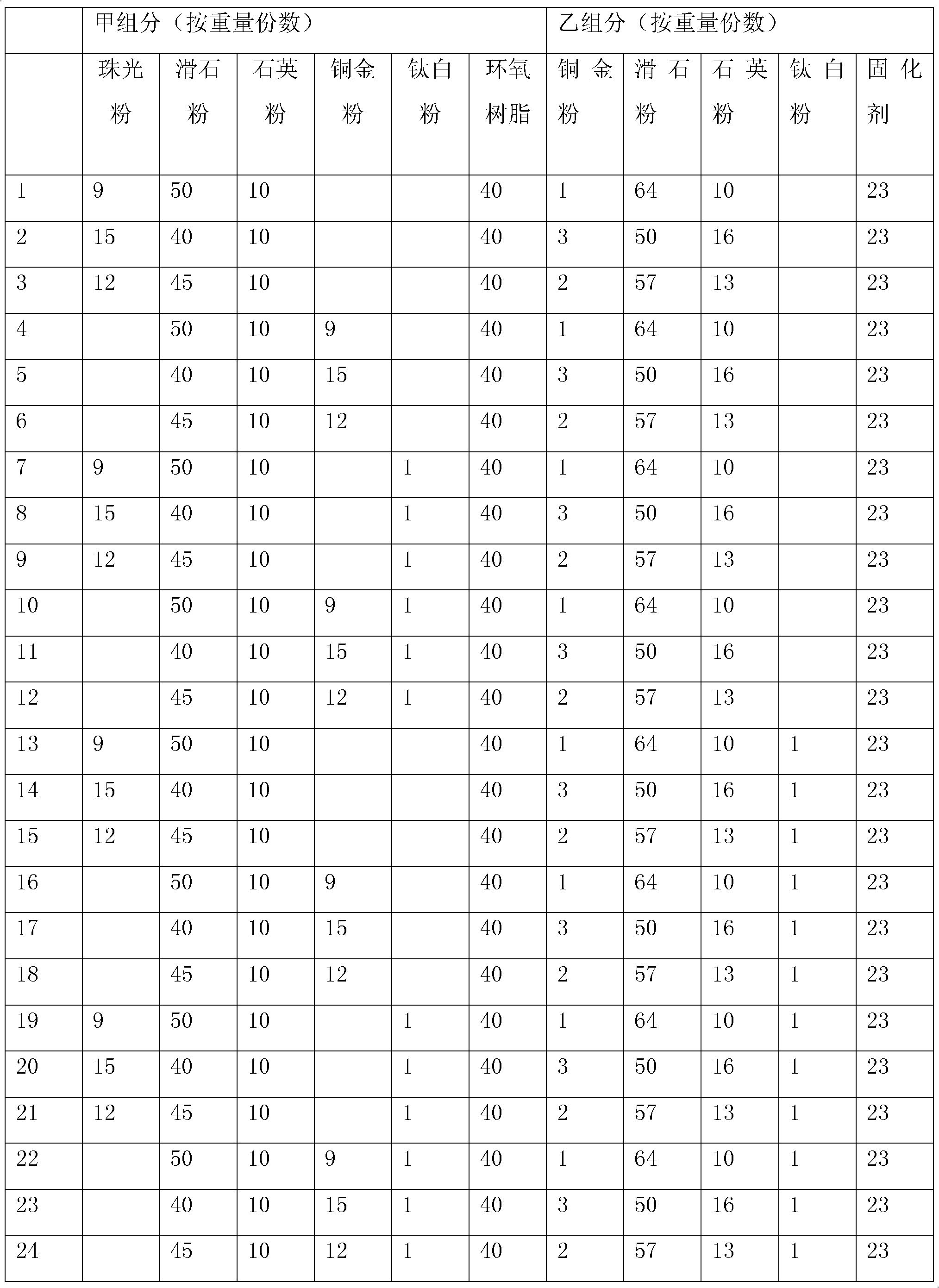

[0022] During preparation, E-44 type epoxy resin and supporting EP type curing agent of Guangzhou Rongsheng Chemical Co., Ltd. can be used. First filler powder is prepared for subsequent use according to the following formula (by weight percentage):

[0023] Component A: 10 parts of pearl powder (SCI-353 model), 40 parts of talc powder, 9 parts of quartz powder, 1 part of titanium dioxide, and 40 parts of epoxy resin. To prepare component A, first mix all kinds of powders evenly, and then Mix well with epoxy resin. Component B: 1.5 parts of copper gold powder, 59.5 parts of talc powder, 15 parts of quartz powder, 1 part of titanium dioxide, 23 parts of curing agent, to prepare component B, first mix all kinds of powder evenly, and then mix with curing agent evenly.

[0024] Before starting to make the hand mold, take 10 kg of component A and 10 kg of component B and mix it evenly before wor...

Embodiment 2

[0025] Example 2: Bronze effect hand mold handprint mud and its preparation process

[0026] During preparation, E-44 type epoxy resin and supporting EP type curing agent of Guangzhou Rongsheng Chemical Co., Ltd. can be used. Filler powder is prepared for subsequent use according to the following formula earlier, (by weight percentage):

[0027] Component A: According to 10 parts of pearl powder (SCI-353), 40 parts of talcum powder, 9 parts of quartz powder, 1 part of titanium dioxide, and 40 parts of epoxy resin, prepare component A. First, mix all kinds of powders evenly, and then Mix well with epoxy resin. Component B: 3 parts of copper gold powder, 64 parts of talcum powder, 9 parts of quartz powder, 1 part of titanium dioxide, 23 parts of curing agent. To prepare component B, first mix all kinds of powders evenly, and then mix them evenly with curing agent.

[0028] Before starting to make the hand mold, take 10 kg of component A and 10 kg of component B and mix it eve...

Embodiment 3

[0029] Example 3: Golden effect hand mold handprint mud and its preparation process

[0030] During preparation, E-44 type epoxy resin and supporting EP type curing agent of Guangzhou Rongsheng Chemical Co., Ltd. can be used. Filler powder is prepared for subsequent use according to the following formula earlier, (by weight percentage):

[0031] Component A: 10 parts of pearl powder (preferred model SCI-353), 40 parts of talc powder, 9 parts of quartz powder, 1 part of titanium dioxide, 40 parts of epoxy resin, to prepare component A, first mix all kinds of powders evenly, Then mix with epoxy resin evenly. Component B: 5 parts of pearl powder (selected model SCI-302), 61 parts of talc powder, 10 parts of quartz powder, 1 part of titanium dioxide, 23 parts of curing agent, and prepare component B, first mix all kinds of powders evenly, Then mix with curing agent evenly.

[0032] Before starting to make the hand mold, take 10 kg of component A and 10 kg of component B and mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com