Thermoplastic elastic self-sealing film and preparation method thereof

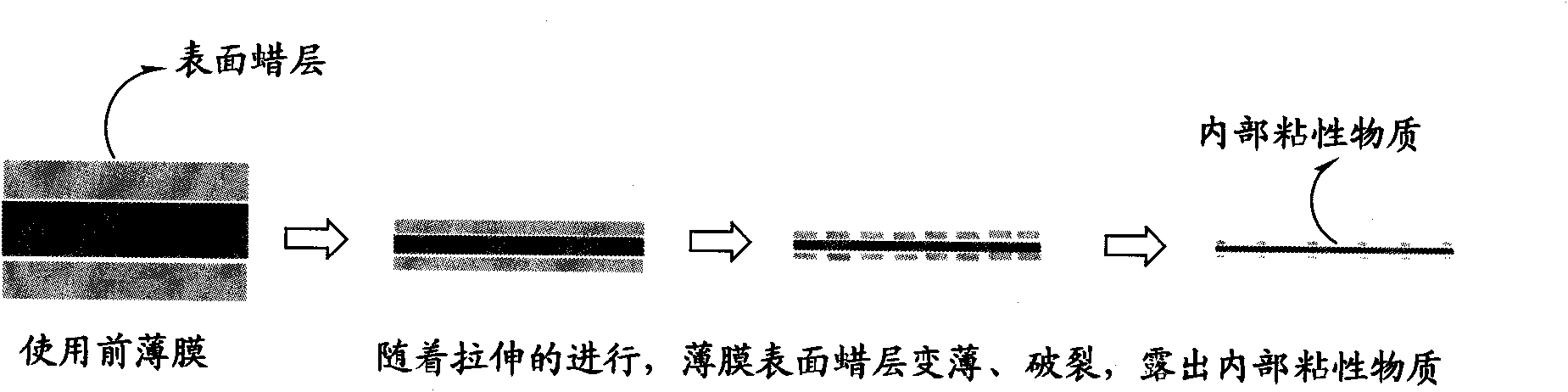

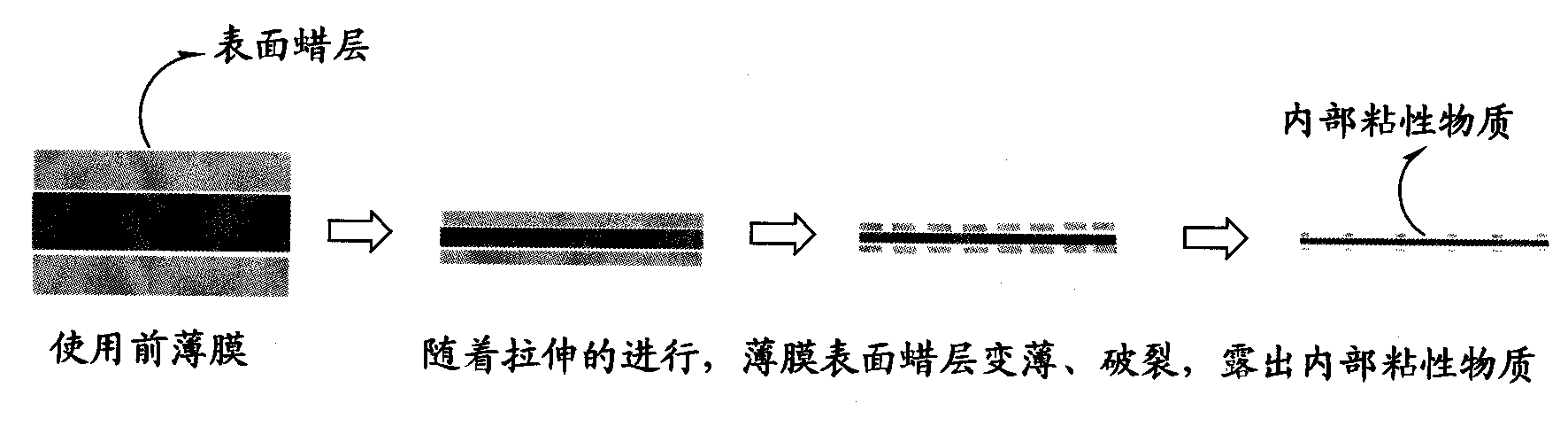

A technology of thermoplastic elasticity and film, which is applied in the direction of film/sheet-shaped adhesives and adhesives, which can solve the problems of unstable air permeability structure, etc., and achieve excellent self-sealing performance, easy transportation, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

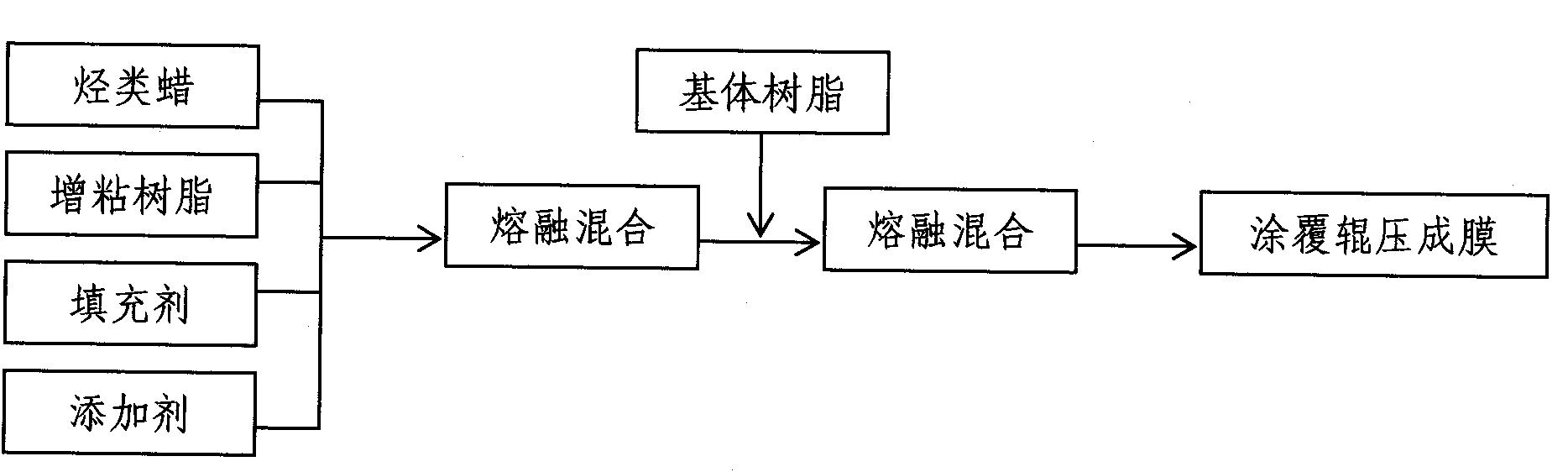

Method used

Image

Examples

Embodiment 1~3

[0036] Table 1 is the formulation composition and performance test results of Examples 1-3. On the basis of Example 1, different thermoplastic elastomers and wax types were selected respectively. The above-mentioned examples have all obtained thermoplastic elastic self-sealing films with good properties. The rigidity and flexibility of the obtained samples are moderate, and the viscosity before use is small. After uniaxial or biaxial stretching, it has good self-adhesive performance, which can meet the requirements of use.

Embodiment 1、 comparative example 4

[0038] Table 2 is the formula ratio and performance test results of Embodiment 1 and Comparative Example 4. Compared with Example 1, Comparative Example 4 increases the proportion of metallocene linear low density polyethylene. The test results show that the 300% tensile modulus of the film increases due to the increase in the proportion of the metallocene linear low density polyethylene in the system, so that the stretching of the film is difficult during use, and the transparency is reduced at the same time.

Embodiment 1、 comparative example 5

[0040] Table 3 is the formula ratio and performance test results of Embodiment 1 and Comparative Example 5. Compared with Example 1, Comparative Example 5 only changes the type of inorganic filler. That is, nano-calcium carbonate was used to replace nano-silica, and the results showed that the transparency of the film filled with nano-calcium carbonate was significantly worse than that of the film filled with nano-silica.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com