Composite damping supporting plate structure for ships

A pallet and ship technology, applied in the direction of hull, hull, hull parts, etc., can solve the problem of no major innovation, achieve good effect of vibration and noise reduction, reduce vibration and sound radiation, and good economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

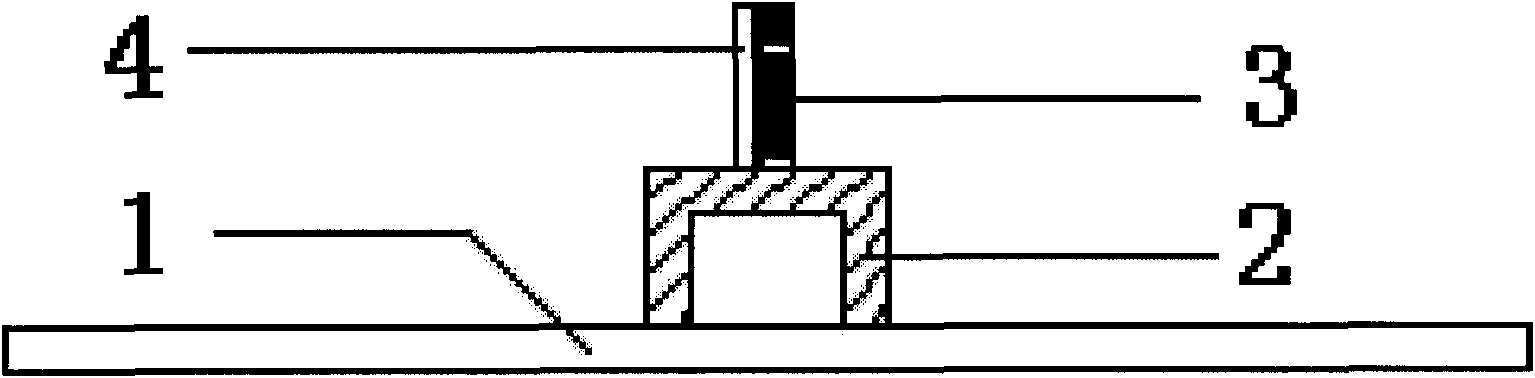

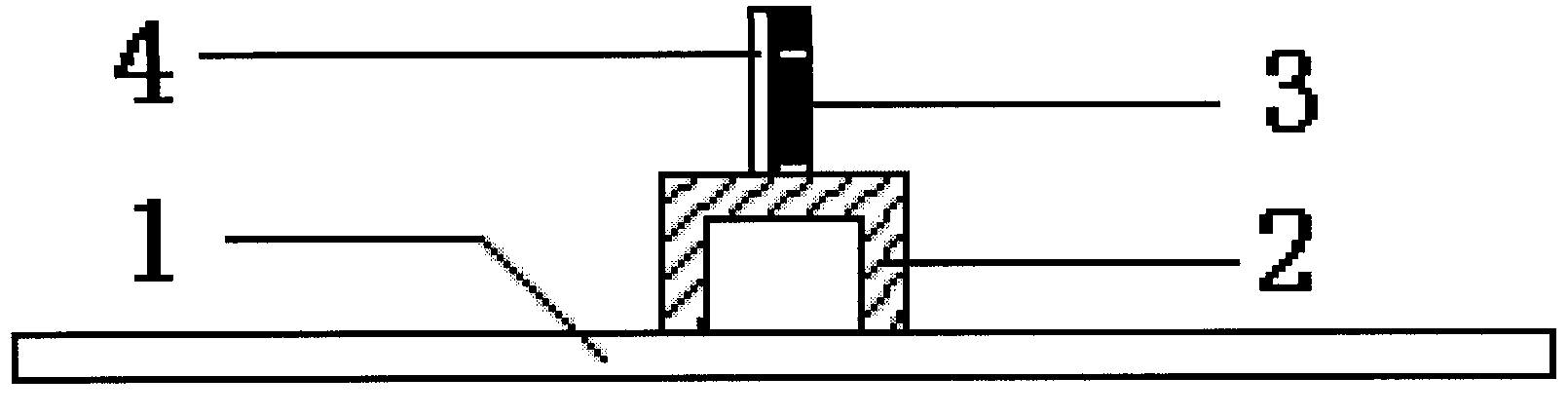

[0015] to combine Figure 1~2 , the ship composite damping supporting plate structure of the present invention comprises a supporting plate 1, a hollow anti-vibration mass 2, a sound-absorbing material 3 and a belt plate 4, the hollow anti-vibration mass 2 is installed on the supporting plate 1, and the hollow anti-vibration mass The block is fixed on one side of the supporting plate, the belt plate 4 is fixed on the hollow vibration-proof mass block 2, and the sound-absorbing material 3 is installed on the belt plate 4. The sound-absorbing material 3 is polyurethane, and the average sound absorption coefficient in the 10-3K frequency band is over 85%. The hollow anti-vibration mass 2 is made of high shear modulus and high-density metal material. The cross-sectional size of the hollow anti-vibration mass 2 is about Torr 8-10 times the thickness of the plate, the weight 2 of the hollow anti-vibration mass should be greater than 60% of the total weight of the solid anti-vibratio...

Embodiment approach 2

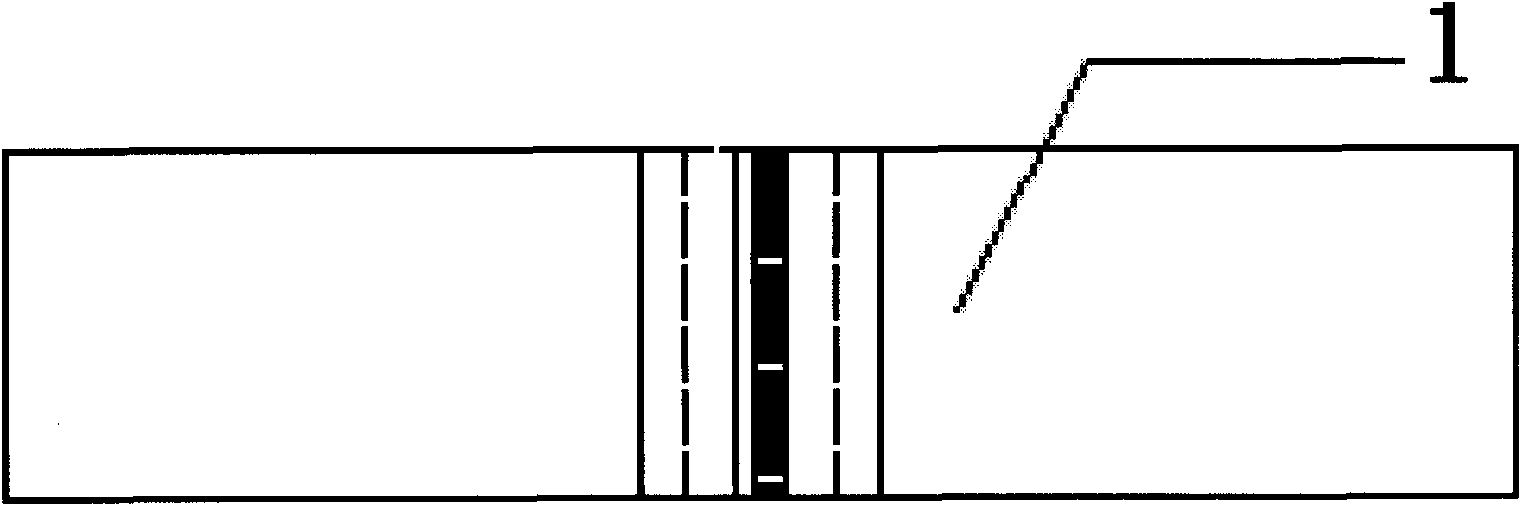

[0022] to combine Figure 1~2 , the ship composite vibration damping pallet structure of the present invention comprises a pallet 1, a hollow vibration damping mass 2, a sound-absorbing material 3 and a belt plate 4, the hollow vibration damping mass 2 is installed on the pallet 1, and the middle of the pallet is disconnected , the hollow anti-vibration mass block is fixed between the two supporting plates. The belt plate 4 is fixed on the hollow anti-vibration mass block 2 , and the sound-absorbing material 3 is installed on the belt plate 4 . The sound-absorbing material 3 is polyurethane, and the average sound absorption coefficient in the 10-3K frequency band is over 85%. The hollow anti-vibration mass 2 is made of high shear modulus and high-density metal material. The cross-sectional size of the hollow anti-vibration mass 2 is about Torr 8-10 times the thickness of the plate, the weight 2 of the hollow anti-vibration mass should be greater than 60% of the total weight o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com