Light automotive rear axle

A lightweight, car technology, applied in the field of auto parts, can solve the problems that magnesium alloys have not been used to manufacture car rear axles, etc., achieve significant market value, reduce noise, and be easy to process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described below in conjunction with the accompanying drawings and specific embodiments.

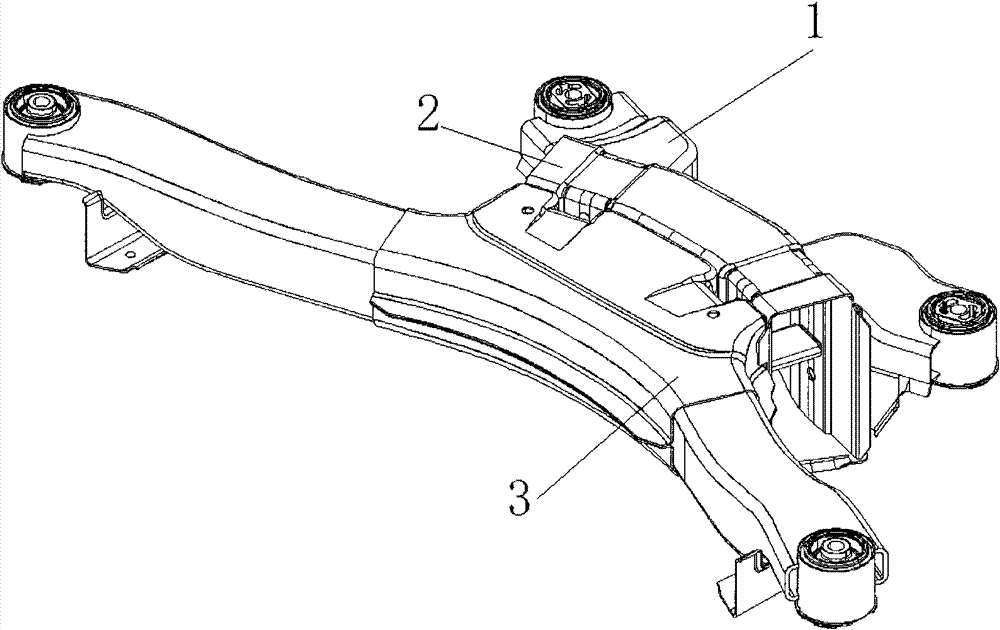

[0022] see figure 1 , a rear axle of a magnesium alloy car in the present invention includes three parts: a front connection welding assembly 1 , a swing arm support box body welding assembly 2 , and a rear connection welding assembly 3 . The three assemblies are welded to each other and positioned according to four elastic supports.

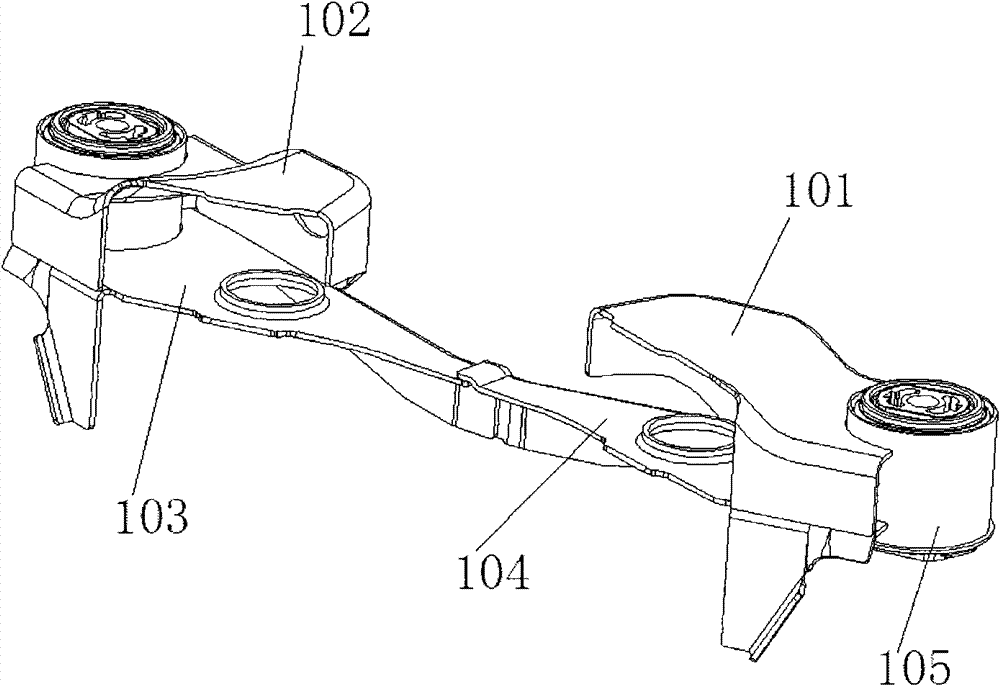

[0023] see figure 2 , Front connection welding assembly 1 is made up of right front cover 101, left front cover 102, left front support plate 103, right front support plate 104, elastic bushing 105. Connect the left and right front support plates to each other first, then weld the left and right front covers 102, 101 on the front support plates 103, 104 respectively, and then install the elastic bushing 105. Process holes are arranged on the left and right front covers 102, 101, which are convenient for installing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com