Profiled air cylinder

A cylinder and special-shaped technology, which is applied in the direction of gang saw machines, fluid pressure actuators, wood processing appliances, etc., can solve the problems such as the cylinder cannot be installed, the knife is not enough, and the thrust of the cylinder is insufficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in conjunction with the following examples.

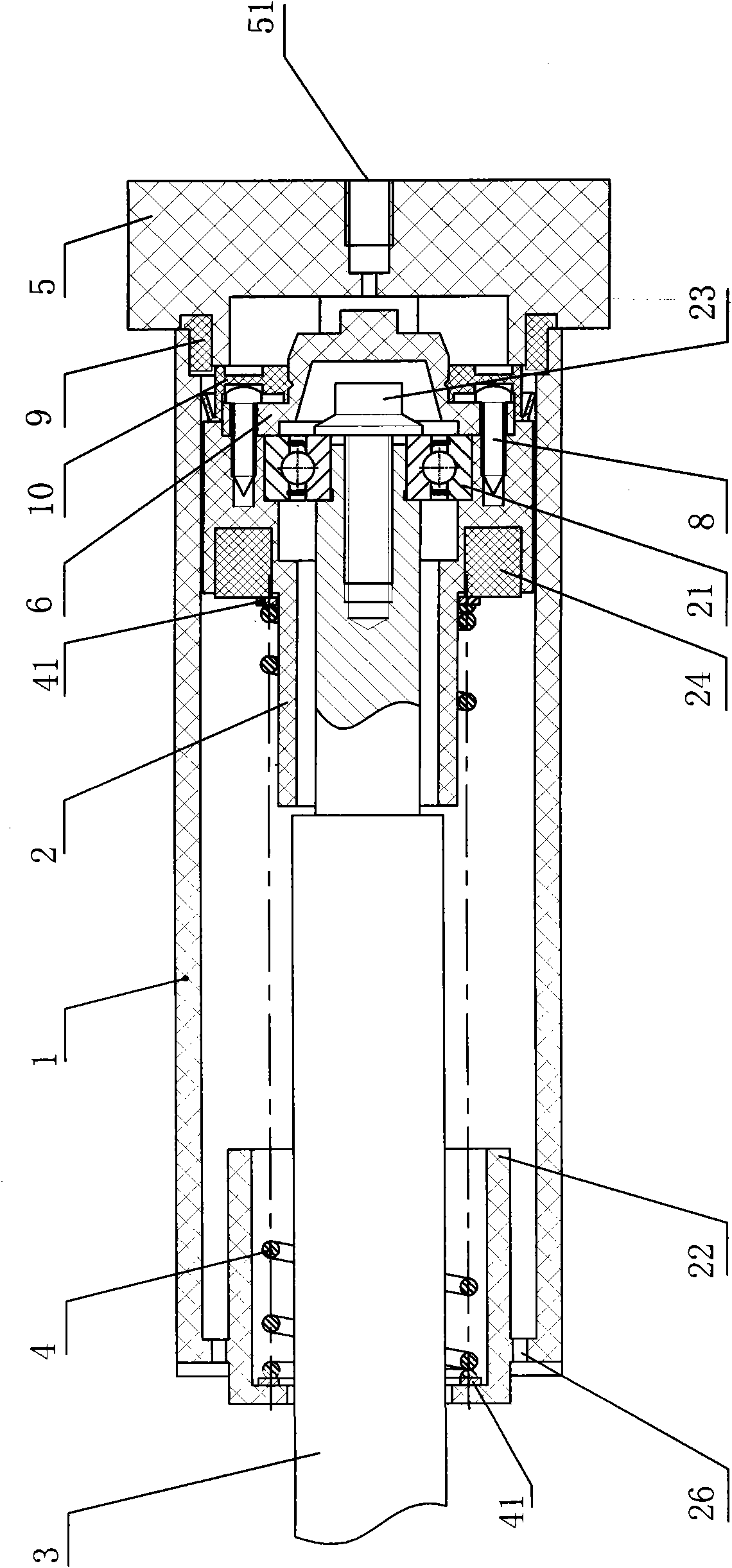

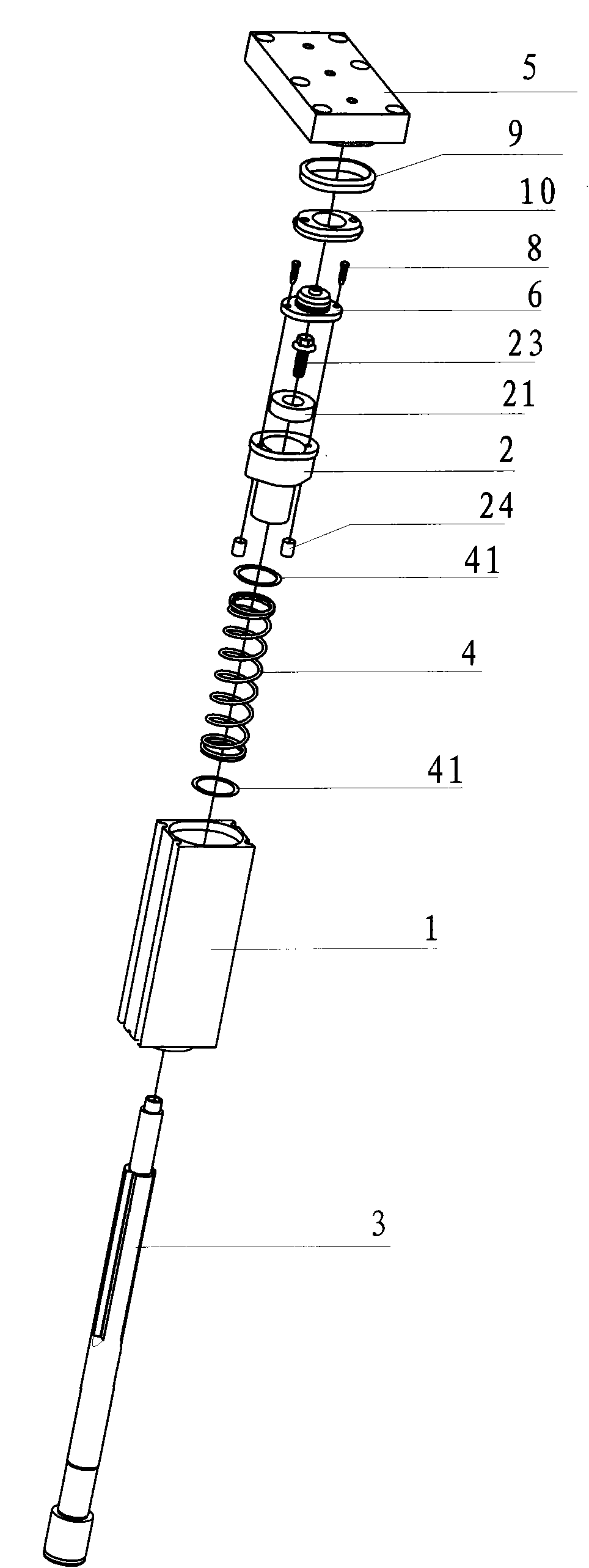

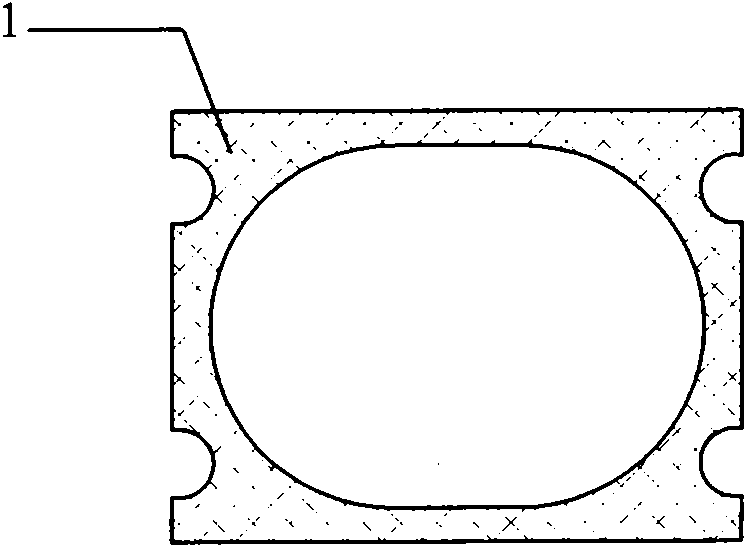

[0030] A special-shaped cylinder, such as figure 1 , figure 2 As shown, a cylinder barrel 1, a piston 2, a piston rod 3, a spring 4 and a cylinder end cover 5 are provided. The cylinder barrel 1 is a plastic cylinder barrel, the piston 2 is a plastic piston, and the cylinder end cap 5 is a plastic cylinder end cap. The cylinder end cover 5 is fixedly connected with the cylinder barrel 1, the piston 2 is installed inside the cylinder barrel 1, the piston rod 3 is fixedly connected with the piston 2 and the piston rod 3 and the piston 2 move inside the cylinder barrel 1.

[0031] Spring 4 is enclosed within piston rod 3 outer walls, and the two ends of spring 4 are respectively provided with a washer 41, and washer 41 is a spring steel washer, and washer 41 can bear the impact of spring 4, protects cylinder barrel 1 and piston 2, prolongs its service life.

[0032] Cylinder b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com