Method for blocking backflow of emulsified liquid with low inertia force

An emulsion, low inertia technology, applied in workpiece surface treatment equipment, metal rolling, manufacturing tools, etc., can solve the problems of increased emulsion consumption, difficult plate shape control, and inconvenient collection of emulsion, and the method is simple. , The effect of preventing the backflow of the emulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

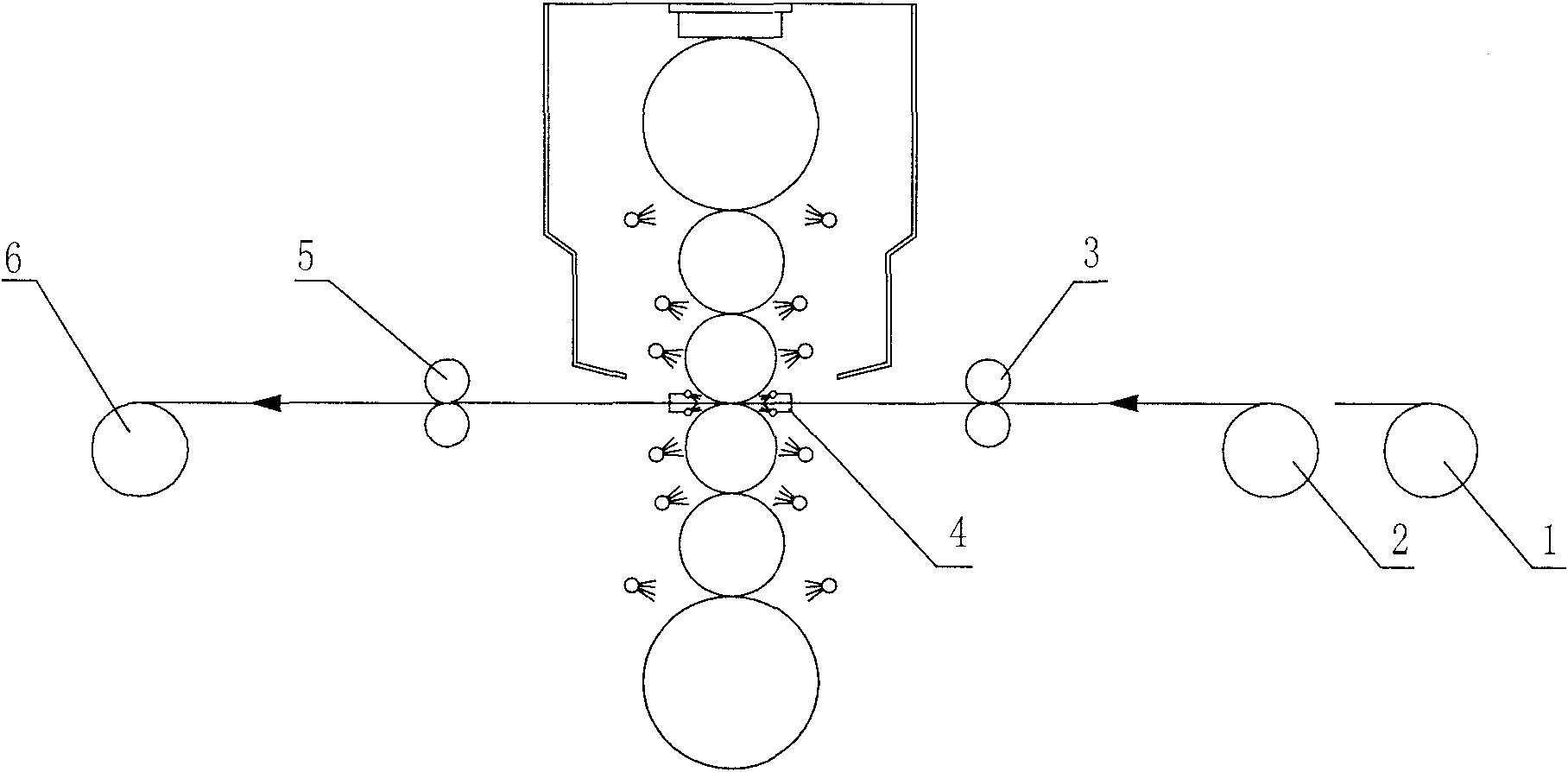

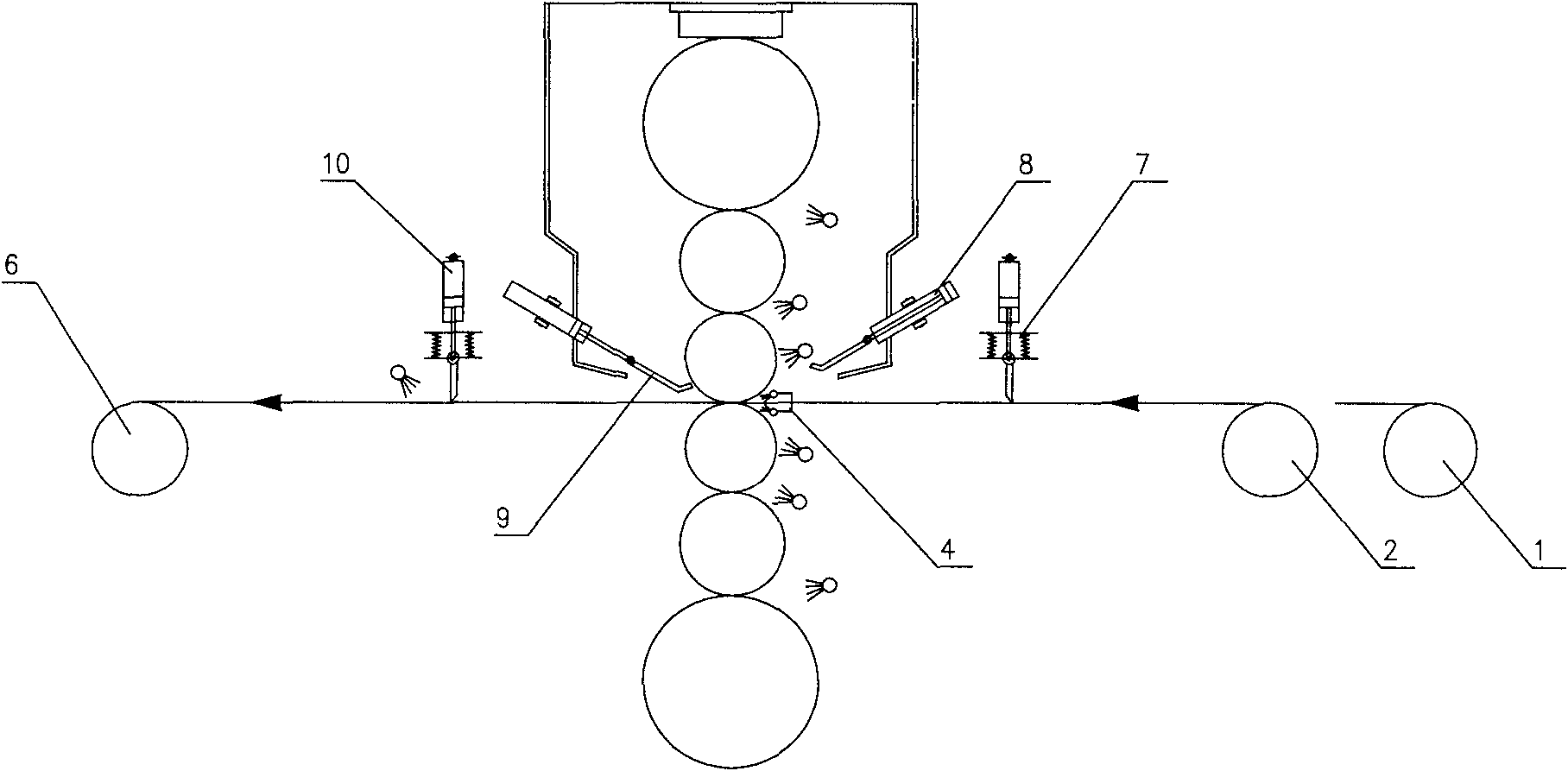

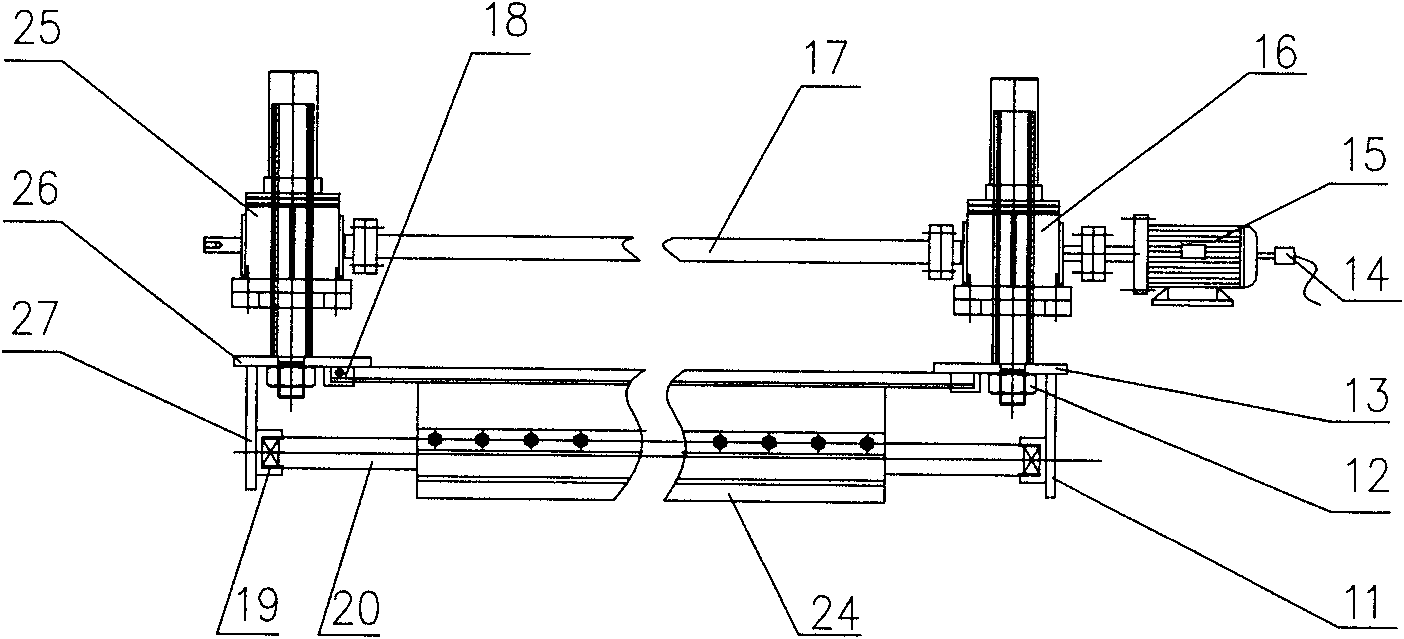

[0014] The blocking method of low inertial force reflux of emulsion, it comprises the steps:

[0015] 1) On the inlet side of the cold rolling mill, an emulsion low inertial force backflow blocking device 7 on the inlet side is installed (located between the inlet coiler 2 and the inlet cooling lubricating fluid injection beam 4), and the emulsion on the inlet side has a low inertial force The rubber scraper of the backflow blocking device 7 is located above the strip steel passing line; the emulsion low inertia force backflow blocking device 10 on the outlet side is installed on the outlet side of the cold rolling mill, and the emulsion low inertia force backflow blocking device 10 on the outlet side The rubber scraper of the device is located above the strip passing line;

[0016] 2) After switching the rolling passes of the rolling mill, when the rolling speed of the cold rolling mill is lower than 4m / s, put down the rubber scraper of the emulsion low inertia force backflow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com