Preparation method of calcium phosphate ceramics/chitosan-hydroxyapatite composite coating porous material

A technology of hydroxyapatite and calcium phosphorus ceramics, which is applied in coatings, medical science, prostheses, etc., can solve the problems of long preparation period, low mechanical properties of composite materials, and unstable process, so as to improve surface biological activity, Good overall performance, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take by weighing chitosan accounting for 1% of the total mass of the solution and dissolve it in an acetic acid solution with a mass concentration of 1%, to make a chitosan-acetic acid solution;

[0028] The mass ratio of hydroxyapatite and chitosan is 2: 1 to take nano-hydroxyapatite powder;

[0029] Adding the nano-hydroxyapatite powder into the chitosan-acetic acid solution, fully stirring to obtain the chitosan-hydroxyapatite suspension;

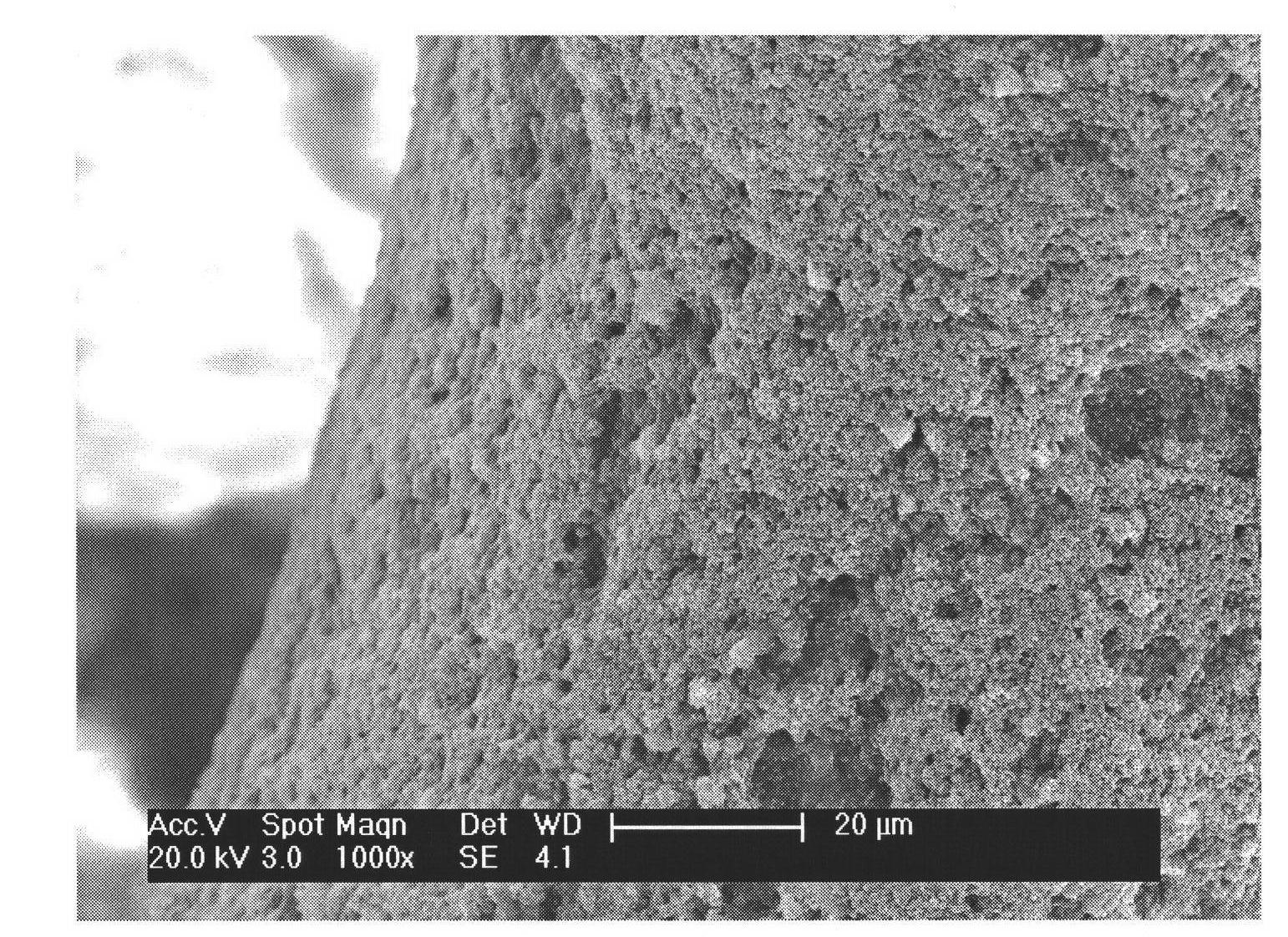

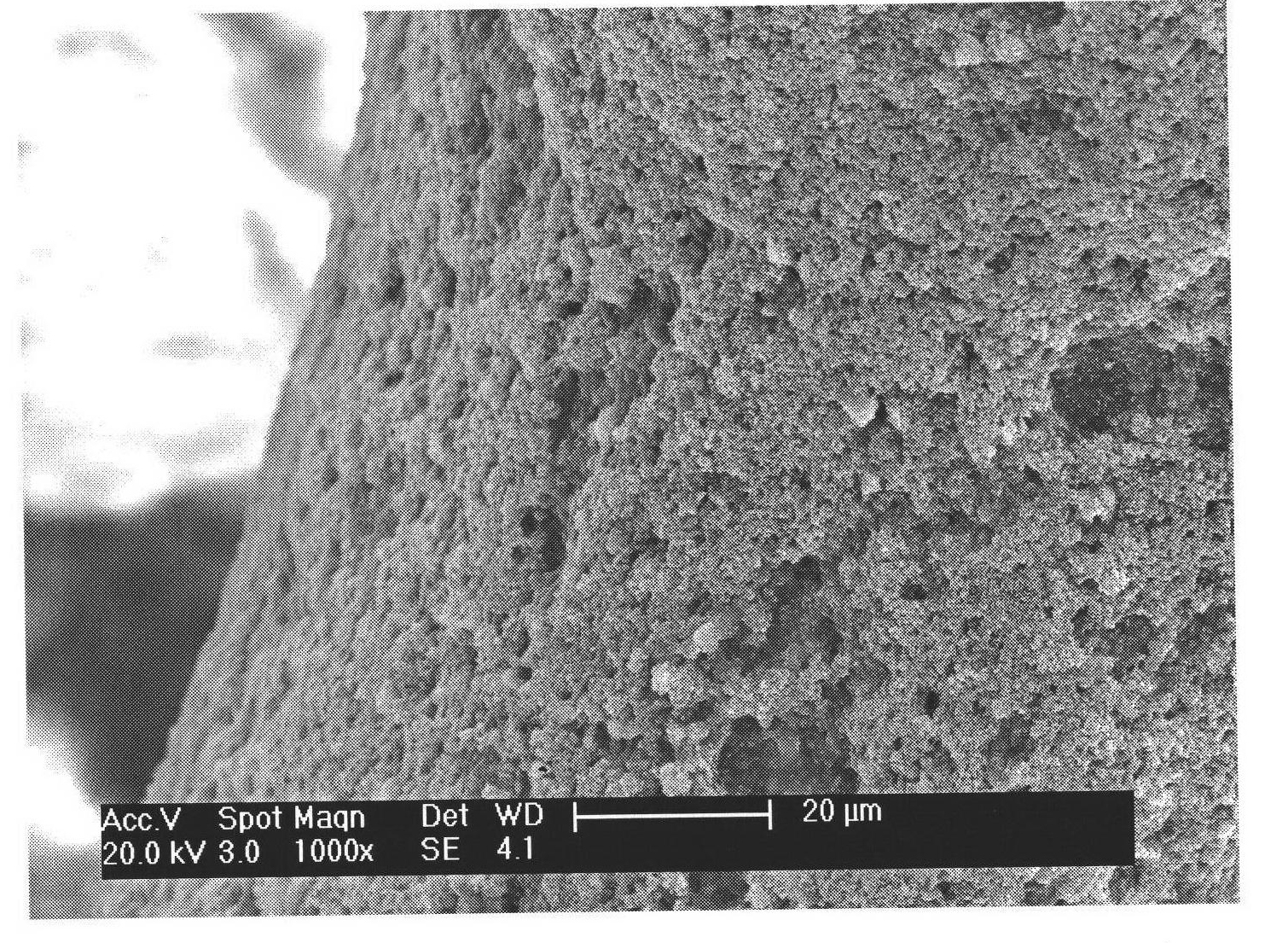

[0030] Slowly immerse the porous calcium phosphorus ceramics with a pore size of 300-600 μm and a network pore structure into the chitosan-hydroxyapatite suspension, and then slowly lift it out after being fully immersed, and centrifuge at 400 rpm in a centrifuge , to remove excess suspension;

[0031] After the coated porous material is dried, it is put into a glutaraldehyde solution with a mass concentration of 0.25% and the crosslinking agent solution is crosslinked for 3 hours, and then cleaned with absolute ethanol to obtain...

Embodiment 2

[0034] Take by weighing chitosan accounting for 5% of the total mass of the solution and dissolve it in the acetic acid solution whose mass concentration is 3%, to make the chitosan-acetic acid solution;

[0035] The mass ratio of hydroxyapatite and chitosan is 1: 1 to take nano-hydroxyapatite powder;

[0036] Adding the nano-hydroxyapatite powder into the chitosan-acetic acid solution, fully stirring to obtain the chitosan-hydroxyapatite suspension;

[0037] Slowly immerse the porous calcium phosphorus ceramics with a pore size of 300-600 μm and a network pore structure into the chitosan-hydroxyapatite suspension, and then slowly lift it out after being fully immersed, and centrifuge it in a centrifuge at 500 rpm , to remove excess suspension;

[0038] After the coated porous material is dried, it is put into a glyoxal solution with a mass concentration of 1.5% and the cross-linking agent solution is cross-linked for 14 hours, and then cleaned with absolute ethanol to obtain...

Embodiment 3

[0040]Take by weighing chitosan accounting for 3% of the total mass of the solution and dissolve it in the acetic acid solution whose mass concentration is 5%, to make chitosan-acetic acid solution;

[0041] The mass ratio of hydroxyapatite and chitosan is 3: 5 to take nanometer hydroxyapatite powder;

[0042] Adding the nano-hydroxyapatite powder into the chitosan-acetic acid solution, fully stirring to obtain the chitosan-hydroxyapatite suspension;

[0043] Slowly immerse the porous calcium-phosphorus ceramics with a pore size of 300-600 μm and a network pore structure into the chitosan-hydroxyapatite suspension, and then lift it out slowly after being fully immersed, and centrifuge at 450 rpm in a centrifuge , to remove excess suspension;

[0044] After the coated porous material is dried, it is put into a formaldehyde solution with a mass concentration of 2.5% and cross-linking agent solution for cross-linking treatment for 24 hours, and then cleaned with absolute ethanol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com