Substrate processing apparatus

A substrate processing device and substrate processing technology, applied in the directions of transportation and packaging, ion implantation plating, gaseous chemical plating, etc., can solve the problems of not being able to sufficiently reduce the overall exclusive area of the device and increase the cost of equipment, and achieve light weight Quantify, suppress equipment cost, and realize the effect of spatialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Next, an embodiment of the substrate processing apparatus of the present invention will be described with reference to the drawings.

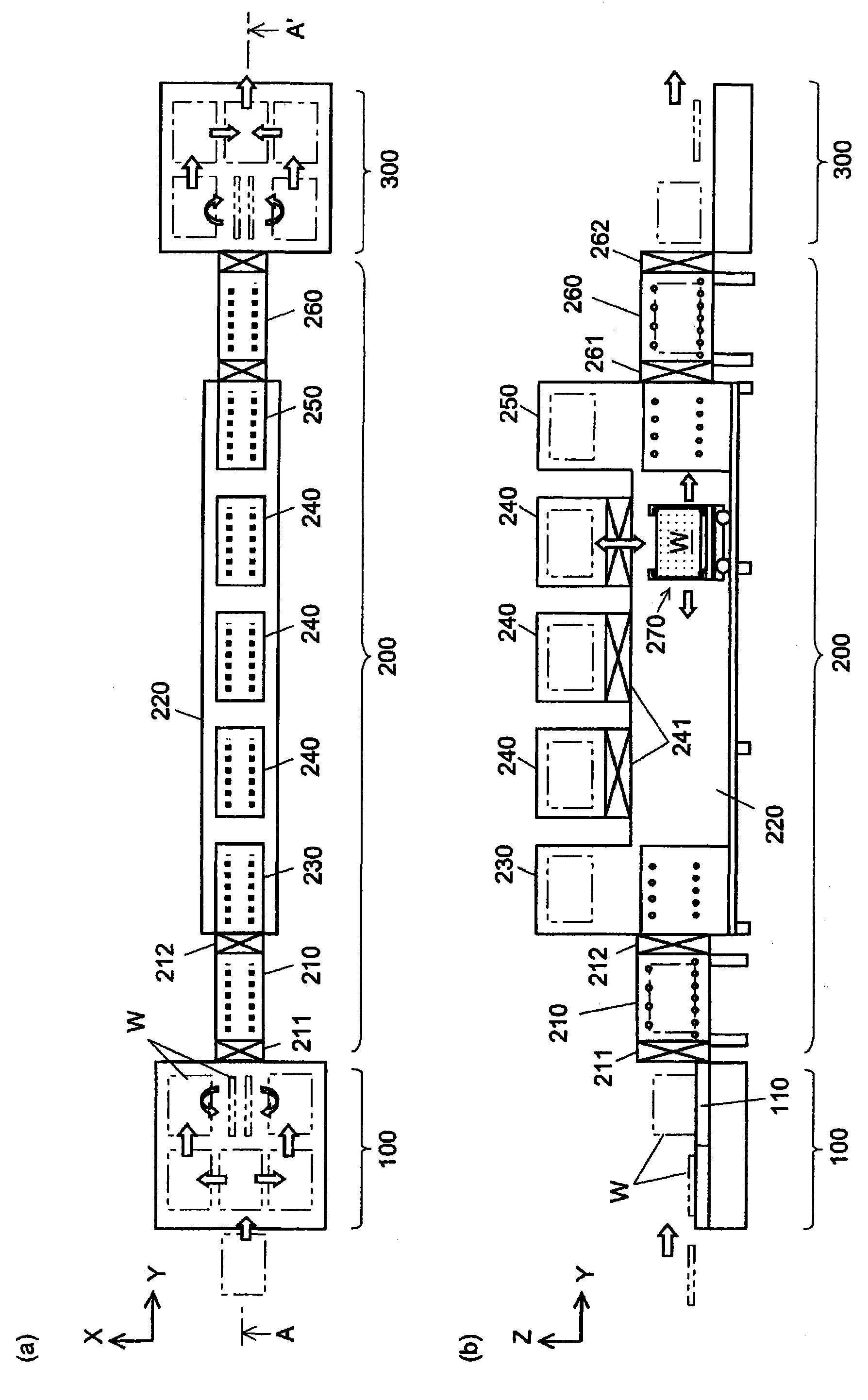

[0055] figure 1It is a schematic configuration diagram of the substrate processing apparatus of this embodiment. The substrate processing apparatus of this embodiment is a PE-CVD apparatus that forms a thin film on a substrate by plasma vapor growth (PE-CVD: Plasma Enhanced Chemical Vapor Deposition). 300 constitutes.

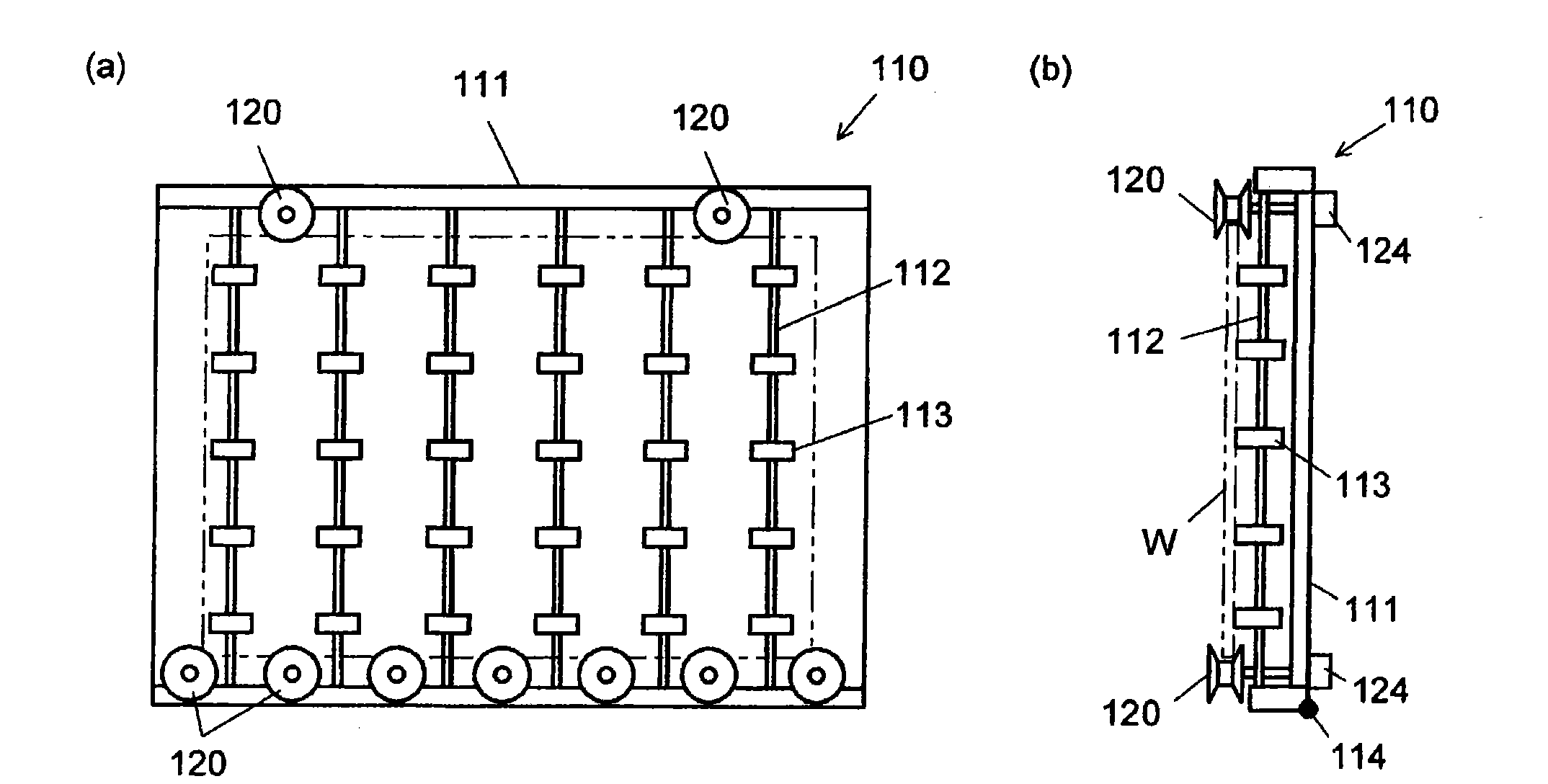

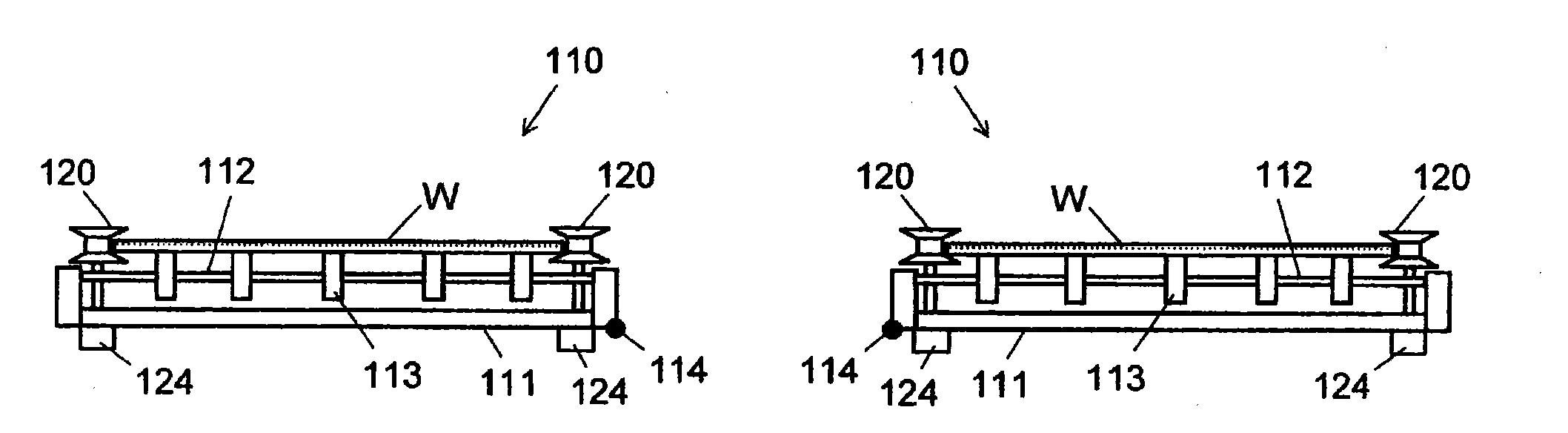

[0056] The processing unit 200 includes: a preheating chamber 230 for preheating the substrate W before processing, a plurality of film forming chambers 240 for forming different thin films on the substrate W, and a plurality of film forming chambers 240 for processing the processed substrate W. Cooling chamber 250 for cooling, pre-vacuum chambers 210 and 260 for carrying substrate W into and out of processing unit 200 , and common transfer chamber 220 including transfer cart 270 for transferring glass substrate W to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com