Real-time detection method for resistance spot welding quality based on electrode displacement fluctuation

A real-time detection, resistance spot welding technology, applied in resistance welding equipment, measuring devices, welding equipment and other directions, can solve the problems of non-pre-detection, large amount of information, low efficiency, etc., to improve accuracy, achieve closed-loop control, speed quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

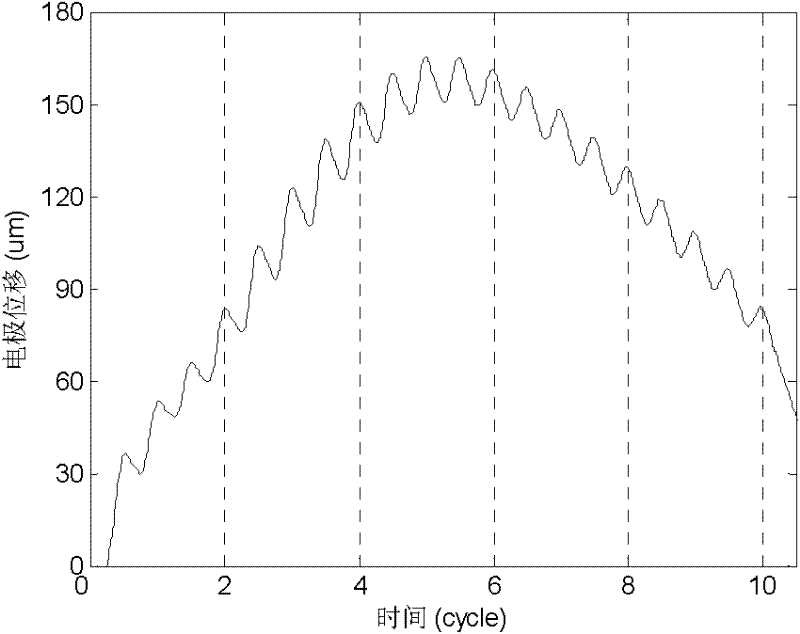

[0032] In this example, low-carbon steel with a thickness of 1mm is taken as an example, and lap resistance welding is performed on a fixed AC spot welding machine. According to the low-carbon steel A-type spot welding specification recommended by the US RWMA, the welding conditions are: frustum-shaped electrode , the diameter of the electrode tip is 5mm, the welding current is 8.8kA, the electrode pressure is 225kg, and the welding time is 10 cycles. The specific steps are:

[0033] The first step is to measure the electrode displacement by using the HEIDENHAIN-SPECT0 grating displacement sensor of the German HEIDENHAIN company, and obtain the real-time displacement signal of the separation of the upper and lower electrodes during the spot welding process, that is, the electrode displacement information.

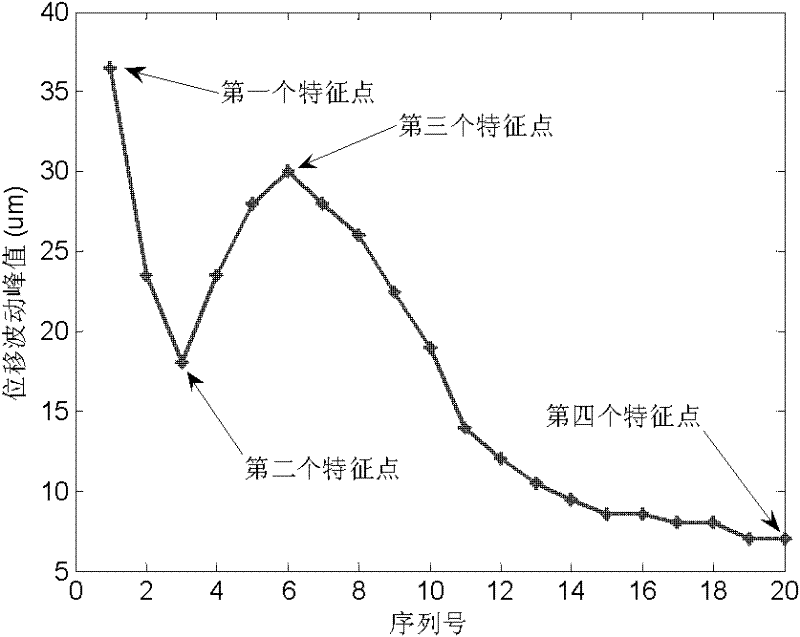

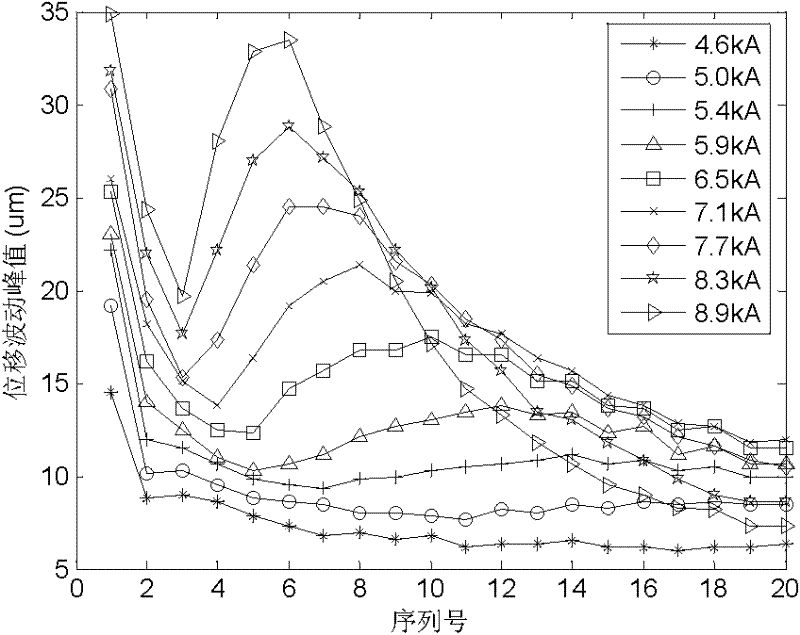

[0034] In the second step, the obtained electrode displacement information is transmitted to the industrial computer, and the industrial computer performs data collection, a...

Embodiment 2

[0050] The difference between this embodiment and embodiment 1 is: the sequence number of the first feature point of the solder joint to be detected is 1, and the peak value of the displacement fluctuation is 39.5um; the sequence number of the second feature point is 3, and the peak value of the displacement fluctuation is 26.5um um; the sequence number of the third feature point is 5, and the displacement peak value is 39.5um; the sequence number of the fourth feature point is 33, and the displacement peak value is 9um.

[0051] The electrode displacement curve of this embodiment is as Figure 5 As shown, the electrode displacement curve of the solder joint to be detected suddenly drops due to splashing, and abnormal fluctuations occur, and the abnormal fluctuation of the electrode displacement curve increases the sequence number of the displacement fluctuation peak curve, which is greater than the threshold T (in this embodiment T=20 ), and its curve fluctuates abnormally af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com