Stress corrosion testing device

A stress corrosion and test device technology, applied in measurement devices, weather resistance/light resistance/corrosion resistance, and application of stable tension/pressure to test the strength of materials, etc. It is difficult to observe the experimental data and other problems, so as to achieve the effect of wide adaptability, convenient control and large reduction ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

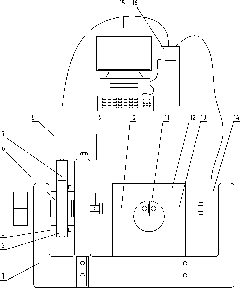

[0017] refer to figure 1 , figure 2 , a stress corrosion test device, including a stress corrosion container 12, a stress application system, and a control test system, wherein a corrosive medium and a sample 11 are installed in the stress corrosion container 12, and the stress corrosion container 12 is installed on a horizontal frame 1; the stress application system includes a transmission part, the transmission part is installed on the horizontal frame 1, the left sample chuck 10 is connected to the transmission part, and the left sample chuck 10 is connected to the right test piece. The sample chuck 13 cooperates to clamp the sample 11; the control test system includes a motor controller 15, an operation terminal 16, a load sensor 14, and the load sensor 14 is installed on the horizontal frame 1, and the right sample chuck 13, the motor controller 17 and the load sensor 14 are connected to the operation terminal 18.

[0018] The stress corrosion container 12 is split up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com