Cooling spray pipe with continuously adjustable jet width

The technology of jet flow and nozzle is applied in the field of quenching and cooling, which can solve the problems that the width of the jet flow of the integral cooling nozzle cannot be adjusted, the spray width can only be adjusted in stages, the energy waste of the water treatment system, etc., and achieves simple structure and cooling quality. The effect of improving and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

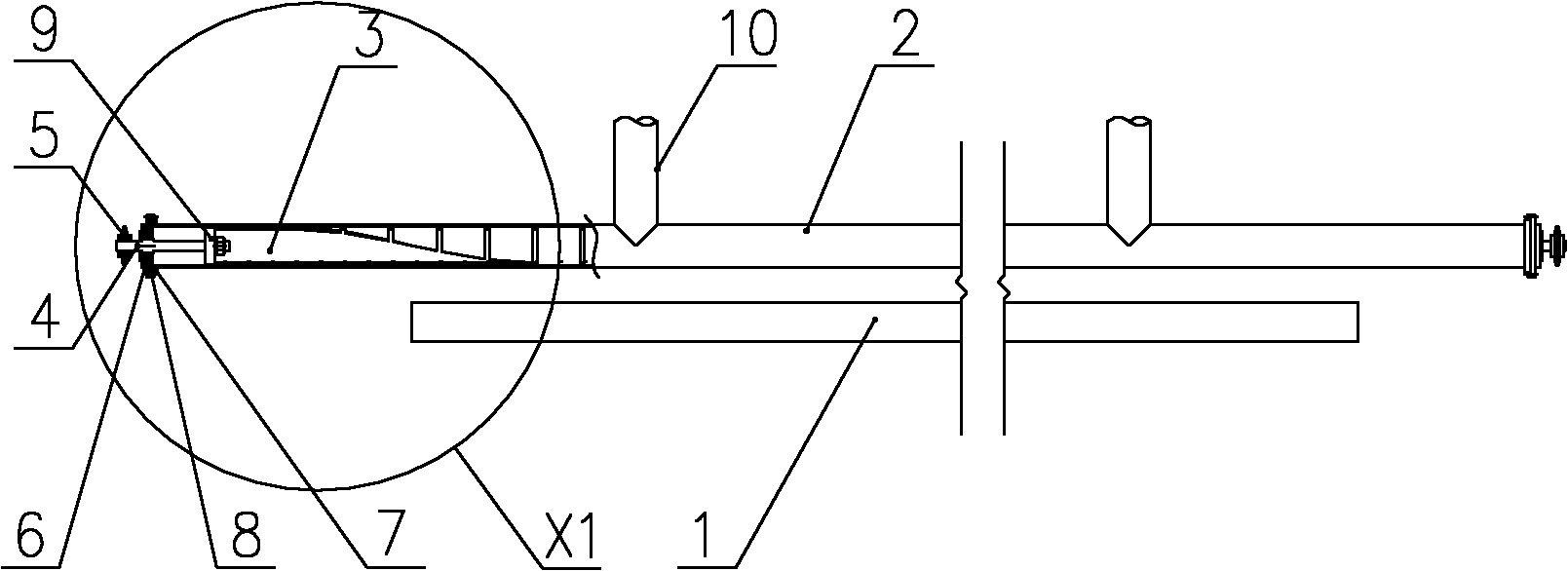

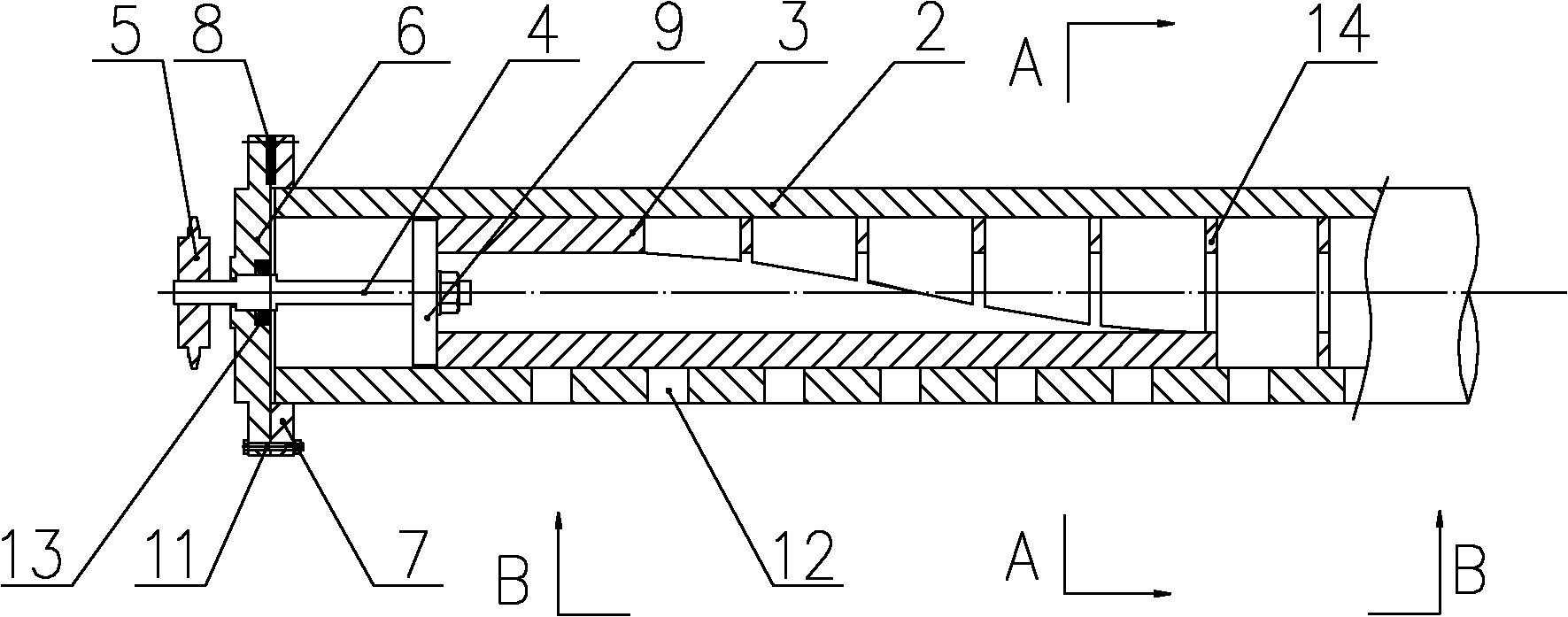

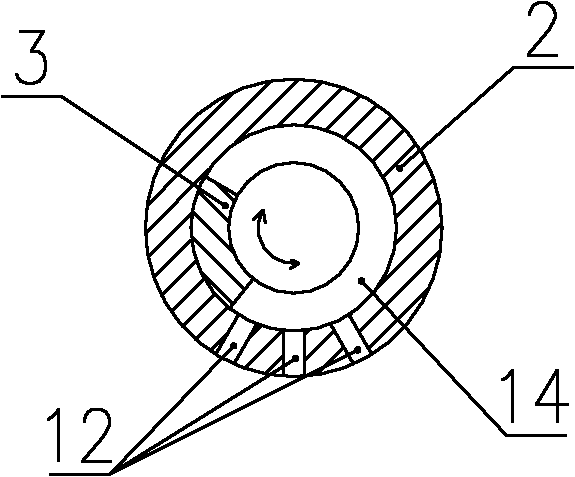

[0025] The cooling nozzle provided by the invention with continuously adjustable jet flow width is a nozzle used for cooling steel plates, steel strips or other plates. Its structure is as Figure 1 to Figure 4 As shown: it includes a cooling medium pipeline 10, a cooling nozzle 2, and a cylindrical plug 3 connected to the cooling nozzle 2 is inserted at both ends of the cooling nozzle 2 respectively. A transmission rod 4 is provided, one end of which is connected to the cylinder plug 3, and the other end is located outside the cooling nozzle 2. Seals are also provided for the end face sealing of the cooling nozzle 2 and the shaft sealing on the transmission rod 4 .

[0026] Described cooling spray pipe 2 is a steel pipe, and in the region facing the cooling steel plate, there are certain arrangements, a certain number, and certain sizes of spray pipe spray holes 12 ( figure 2 ), for example: one row, the hole spacing is 30mm, and the hole diameter is 3.5mm. The nozzle hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com