Post-welding rapid cooling equipment for high-end equipment manufacturing

A post-welding and equipment technology, which is applied in the field of rapid cooling equipment after welding for high-end equipment manufacturing, can solve the problems of inability to flexibly control the cooling range, large loss, and low welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

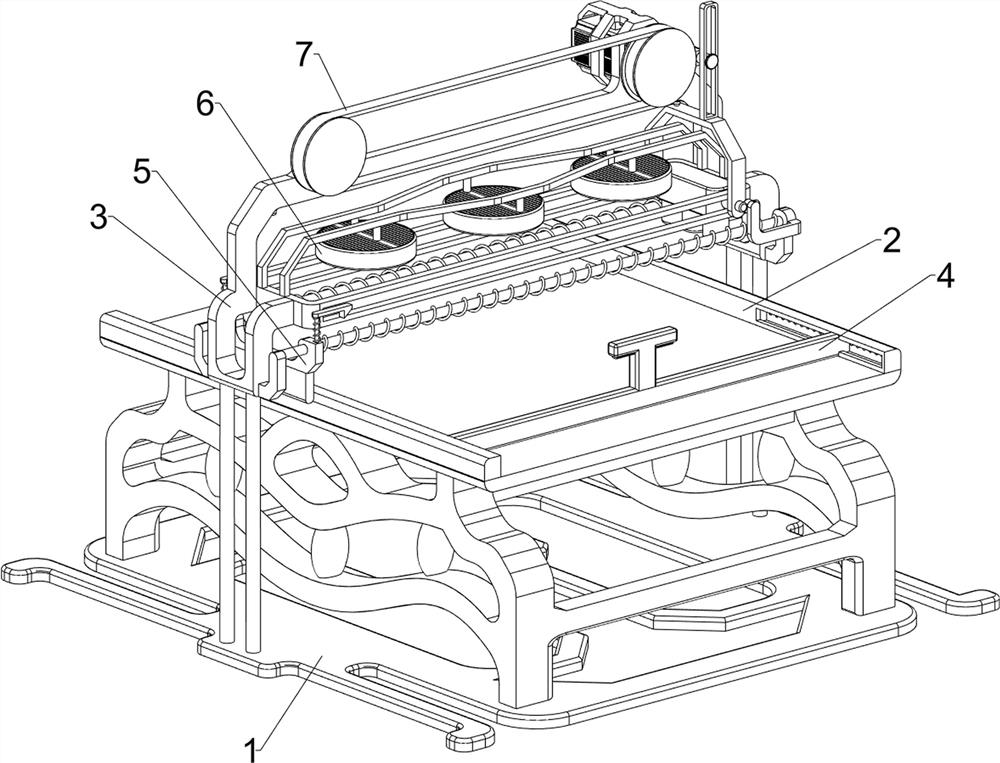

[0028] A rapid cooling equipment after welding for high-end equipment manufacturing, such as Figure 1-Figure 4 As shown, it includes a base 1 , a placement component 2 and a sprinkling component 3 . The top of the base 1 is provided with a placement component 2 , and the top of the base 1 is provided with a sprinkling component 3 .

[0029] People place the welded high-temperature metal on the placement component 2, and move the sprinkler component 3 to spray water to cool the high-temperature metal, so as to achieve the effect of simple structure and convenient operation.

[0030] The placement assembly 2 includes a first support frame 21, a placement plate 22 and a baffle plate 23. The top of the base 1 is provided with a first support frame 21, and the top of the first support frame 21 is provided with a placement plate 22. Baffle 23.

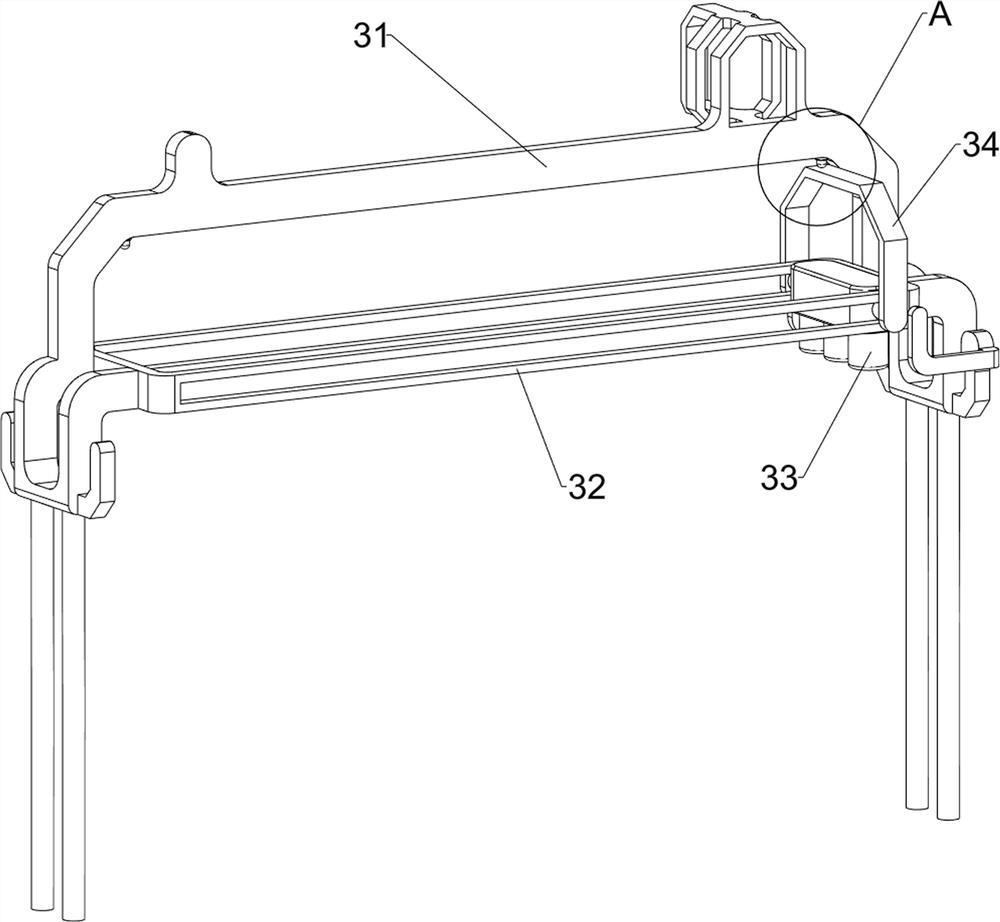

[0031] The sprinkler assembly 3 includes a second support frame 31, a first slide rail 32, a sprinkler head 33, a first connecting rod 34...

Embodiment 2

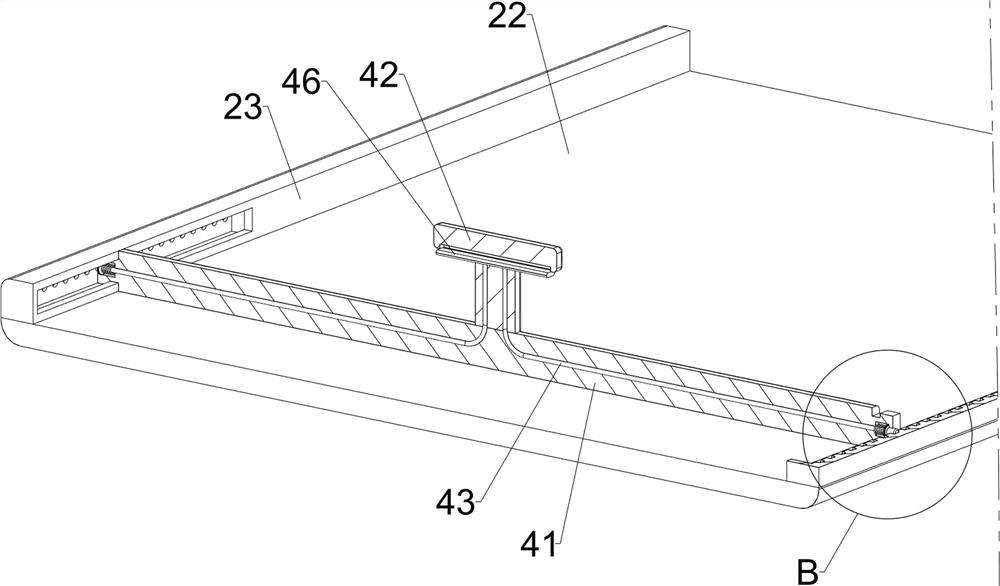

[0034] On the basis of Example 1, such as Figure 5-Figure 9 As shown, a positioning assembly 4 is also included, and the positioning assembly 4 includes a blocking rod 41, a handle 42, a stay cord 43, a second connecting rod 44, a first spring 45 and a third connecting rod 46, and the front side of the top of the blocking plate 23 The sliding type is provided with stop bar 41, and the top of stop bar 41 is provided with handle 42, and the sliding type on handle 42 is provided with the 3rd connecting rod 46, and the left and right symmetrical sliding type of stop bar 41 is provided with the second connecting rod 44, and Sliding fit between the second connecting rod 44 and the baffle plate 23, a pull cord 43 is connected between the second connecting rod 44 and the third connecting rod 46, and a first connecting rod 44 is connected with the blocking rod 41. Spring 45.

[0035] When people need to cool down the high-temperature metal, the third connecting rod 46 on the lower si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com