Method for producing hydrogen by utilizing facultative anaerobe fermentation

A facultative anaerobic bacteria and fermentation substrate technology, applied in the field of biological hydrogen production, can solve the problems of strict fermentation conditions and complex operation of biological hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: Selection and determination of bacterial strain inoculation methods

[0027] The medium components are: peptone 5g / L, beef extract 3g / L, NaCl 5g / L, adjust the initial pH=7.0, and use this as the basic medium; all sterilization is performed at 115°C for 25 minutes;

[0028](1) Scheme 1: prepare the basic medium and sterilize it, inoculate the Enterobacter aerogenes high-concentration bacterial solution in the basic medium with a volume ratio of 2% to 5% (aseptic operation), and inoculate the base medium at a temperature of 30°C and 170r / min After 24-48 hours of shaking culture on a shaking table, transfer the cultured bacterial liquid to the sterilized glucose fermentation substrate with a concentration of 20g / L. The total amount of the fermentation liquid is 450mL. 170r / min shaker shake culture, and connect the hydrogen collection device.

[0029] (2) Scheme 2: Add glucose to the base medium at a ratio of 20g / L as a fermentation substrate, obtain a cultur...

Embodiment 2

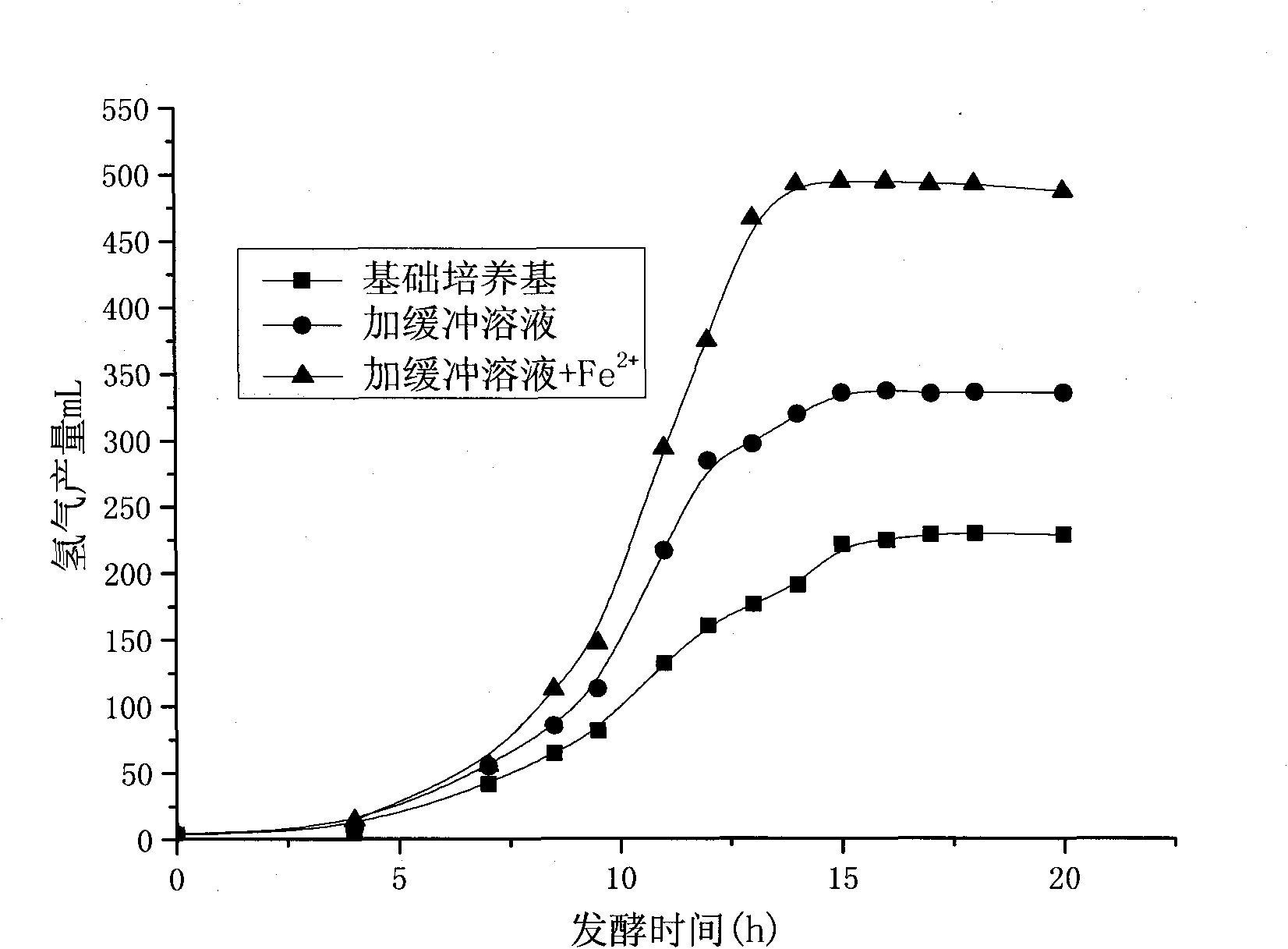

[0032] Embodiment 2: Determination of optimal fermentation base component configuration

[0033] According to the result of embodiment 1, on the basis of application scheme two, further optimize fermentation condition, explore the best fermentation medium component configuration, carry out following test:

[0034] Three kinds of fermentation media were prepared respectively, numbered 1 to 3, and their compositions were shown in the table below:

[0035] Medium No.

Glucose 20g / L

Peptone 5g / L

Beef Extract 3g / L

NaCl 5g / L

K 2 HPO 4 1.5g / L

FeSO 4 4H 2 O 0.2g / L

1

+

+

+

+

2

+

+

+

+

+

3

+

+

+

+

+

+

[0036] Adjust the initial pH of the fermentation medium to 7.0, sterilize at 115°C for 25 minutes, inoculate Enterobacter aerogenes high-concentration bacterial liquid at a volume ratio of 2% to 5% (aseptic op...

Embodiment 3

[0038] Embodiment 3: the determination of optimum fermentation substrate concentration

[0039] According to the results of Examples 1 and 2, the possibility of improving the hydrogen production efficiency was explored by changing the initial concentration of the fermentation substrate.

[0040] Prepare basal medium, consisting of: peptone 5g / L, beef extract 3g / L, NaCl 5g / L, K 2 HPO 4 1.5g / L, FeSO 4 4H 2 O 0.2g / L, set 4 groups of parallel experiments, set the initial substrate glucose concentration as 5, 10, 20, 30, 40 and 60g / L respectively, the total fermentation liquid volume is 450mL, other fermentation conditions are all the same. Before the start of the culture, they were purged with nitrogen for 3-5 minutes to an anaerobic or near-anaerobic environment, placed on a shaker at a temperature of 40 ° C, 170 r / min for shaking culture and connected to a hydrogen collection device, and the duration was 20 hours. The gas is collected during the fermentation process, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com