Method for preparing plant ash saturated aqueous solution and application thereof

A plant ash and water solution technology, which is applied in the field of preparation of plant ash saturated aqueous solution, can solve problems such as inconvenient spreading, nitrogen volatilization loss, single nutrition, etc., and achieves the effects of easy operation, low operating cost, simple equipment and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 The preparation method of plant ash saturated aqueous solution and its application in granulation potash fertilizer process

[0034] A preparation method of plant ash saturated aqueous solution, comprising the following steps:

[0035] (1) Pulping: Mix 250KG of plant ash in the raw pulp tank, soak for 3 hours, and make mixed mortar A and provide it to the mixing process;

[0036] (2) Mixing: Start the first mortar pump, suck the mixed mortar A and flush it into the raw slurry pool again, so as to obtain a homogeneous mortar B with uniform concentration and provide it to the solid-liquid separation process;

[0037] This process is carried out continuously;

[0038] (3) Solid-liquid separation in the early stage: start the second mortar pump, extract the homogeneous mortar B and input it into the first centrifugal drum type solid-liquid separator for solid-liquid separation, and recover the separated solid dregs D1, and the separated liquid It flows back into...

Embodiment 2

[0049] Example 2 The preparation method of plant ash saturated aqueous solution and its application in granulation potash fertilizer process

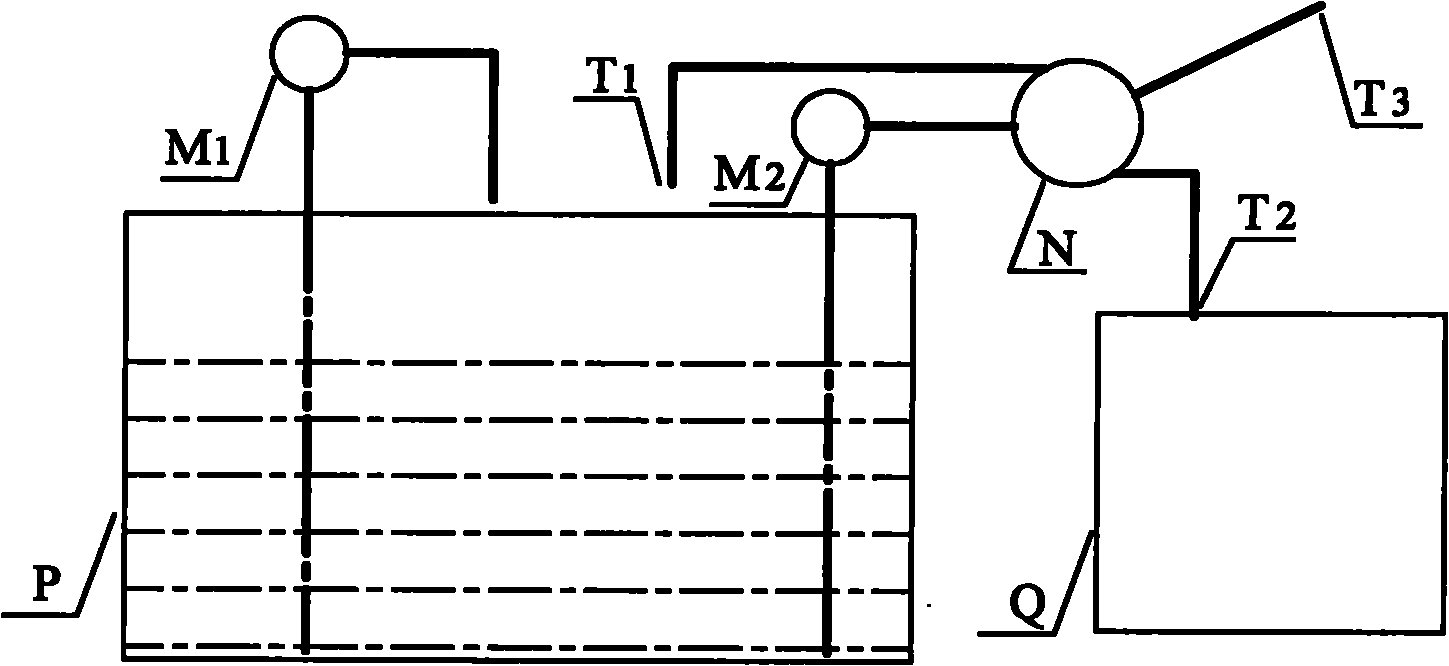

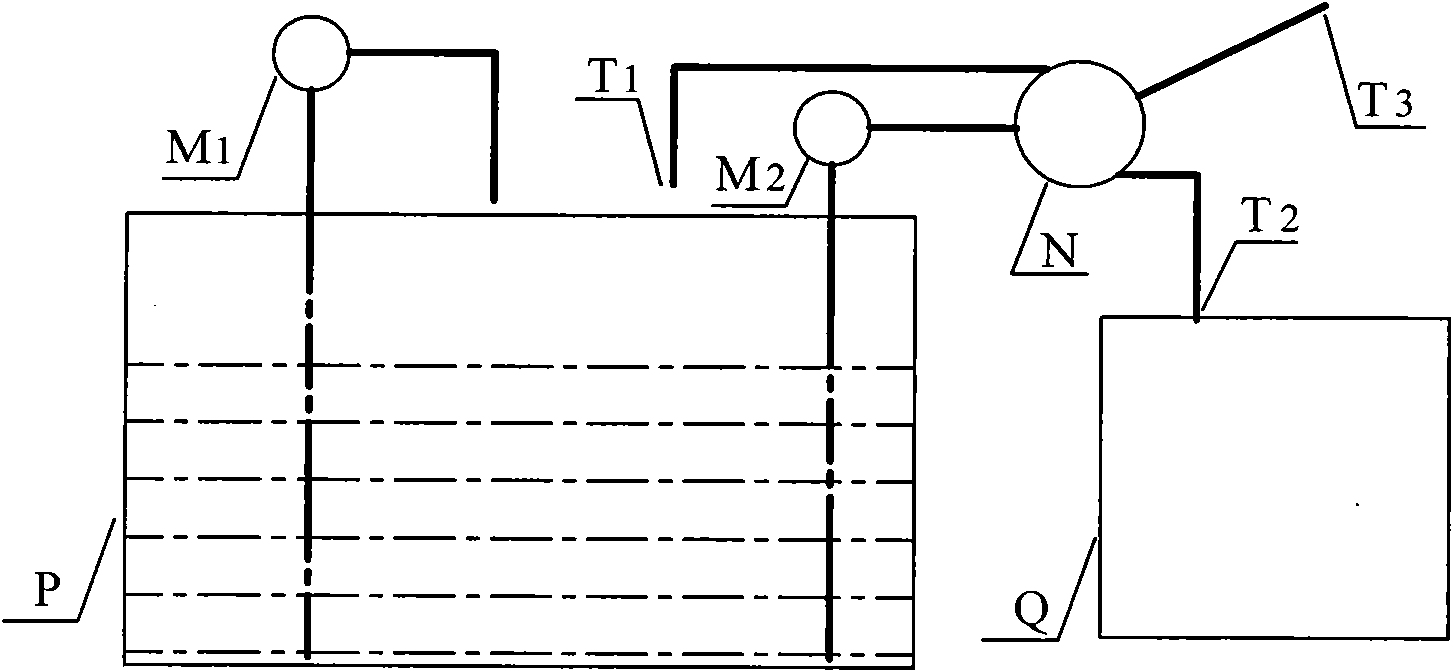

[0050] A kind of preparation method of plant ash saturated aqueous solution utilizes figure 1 The facilities shown are implemented. The preparation method comprises the following steps:

[0051] (1') Pulping: in the raw pulp pool P, plant ash and 100KG of water were mixed, soaked for 2 hours, and the mixed mortar A was obtained and provided to the mixing process;

[0052] (2') Mixing: Start the first mortar pump M1, suck the mixed mortar A and flush it into the raw slurry pool P again, so as to obtain a homogeneous mortar B with uniform concentration and provide it to the solid-liquid separation process;

[0053] This process is carried out continuously;

[0054] (3') Solid-liquid separation in the early stage: start the second mortar pump M2, extract the homogeneous mortar B and input it into the centrifugal drum type solid-liquid s...

Embodiment 3

[0064] Example 3 The preparation method of plant ash saturated aqueous solution and its application in granulation potash fertilizer process

[0065] (1 ″) Pulping: Mix 100KG each of plant ash and water in the raw pulp pool, soak for 4 hours, and make mixed mortar A and provide it to the mixing process;

[0066] (2″) Mixing: Start the first mortar pump, suck the mixed mortar A and flush it into the raw slurry pool again, so as to obtain a homogeneous mortar B with uniform concentration and provide it to the solid-liquid separation process;

[0067] This process is carried out continuously;

[0068] (3″) Solid-liquid separation in the early stage: start the second mortar pump, extract the homogeneous mortar B and input it into the centrifugal drum type solid-liquid separator for solid-liquid separation, the inlet of the centrifugal drum type solid-liquid separator is connected with the first The two mortar pumps are connected, and the discharge port is connected with the raw p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com