Soft sheet film method waste water treatment intensive device

A waste water treatment and film technology, which is applied in the direction of osmosis/dialysis water/sewage treatment, ultrafiltration, etc., can solve the problems of complicated pipeline connection, troublesome manual operation, and large floor space, and achieve high filtration accuracy, easy maintenance, and small footprint. small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below with reference to the accompanying drawings.

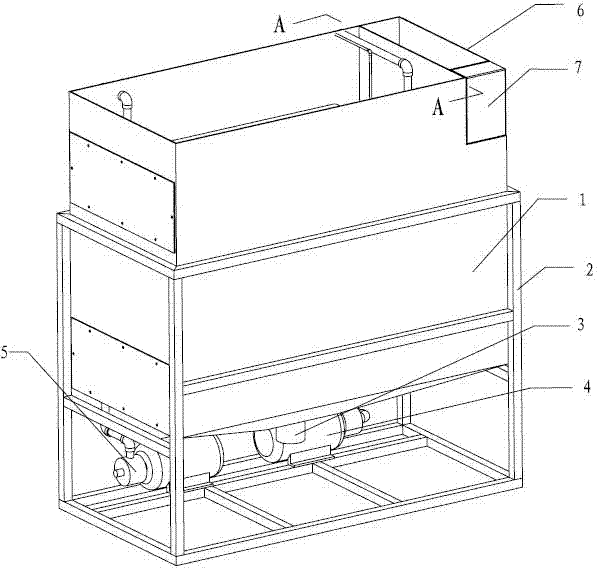

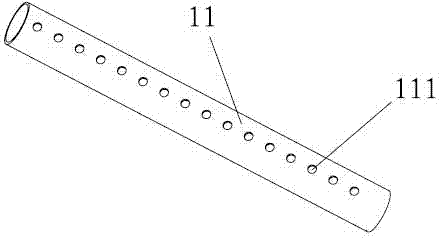

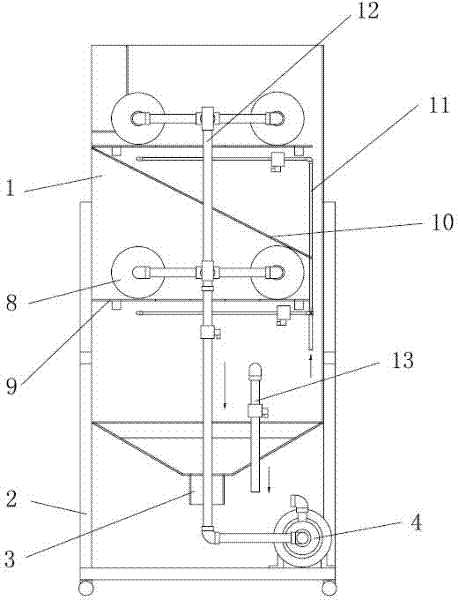

[0016] The box housing 1 is installed on the support 2, and the backwash water storage tank 6, the electric control box 7, the raw water pump 5 and the filtered water pump 4 positioned at the bottom of the support are also installed on the support 2. In this embodiment, the box shell 1 is a cuboid, the bottom of which is a cone, and the top of the cone is provided with a concentrated water discharge interface 3, and the lower part of the box shell is also provided with a secondary concentrated water discharge interface 13; A supporting plate 9 installed horizontally, the three sides of the two supporting plates 9 are in sealing contact with the inner wall of the box shell 1, and a certain gap is reserved between one side and the inner wall of the box shell 1; each supporting plate 9 There are two cylindrical ultrafiltration membrane locking components 8 which are success...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com