Method for continuously synthesizing phosphorous acid

A phosphorous acid, chemical synthesis technology, applied in the direction of phosphorous acid, phosphorus oxyacid, etc., can solve the problems such as no continuous production of phosphorous acid industrialization method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

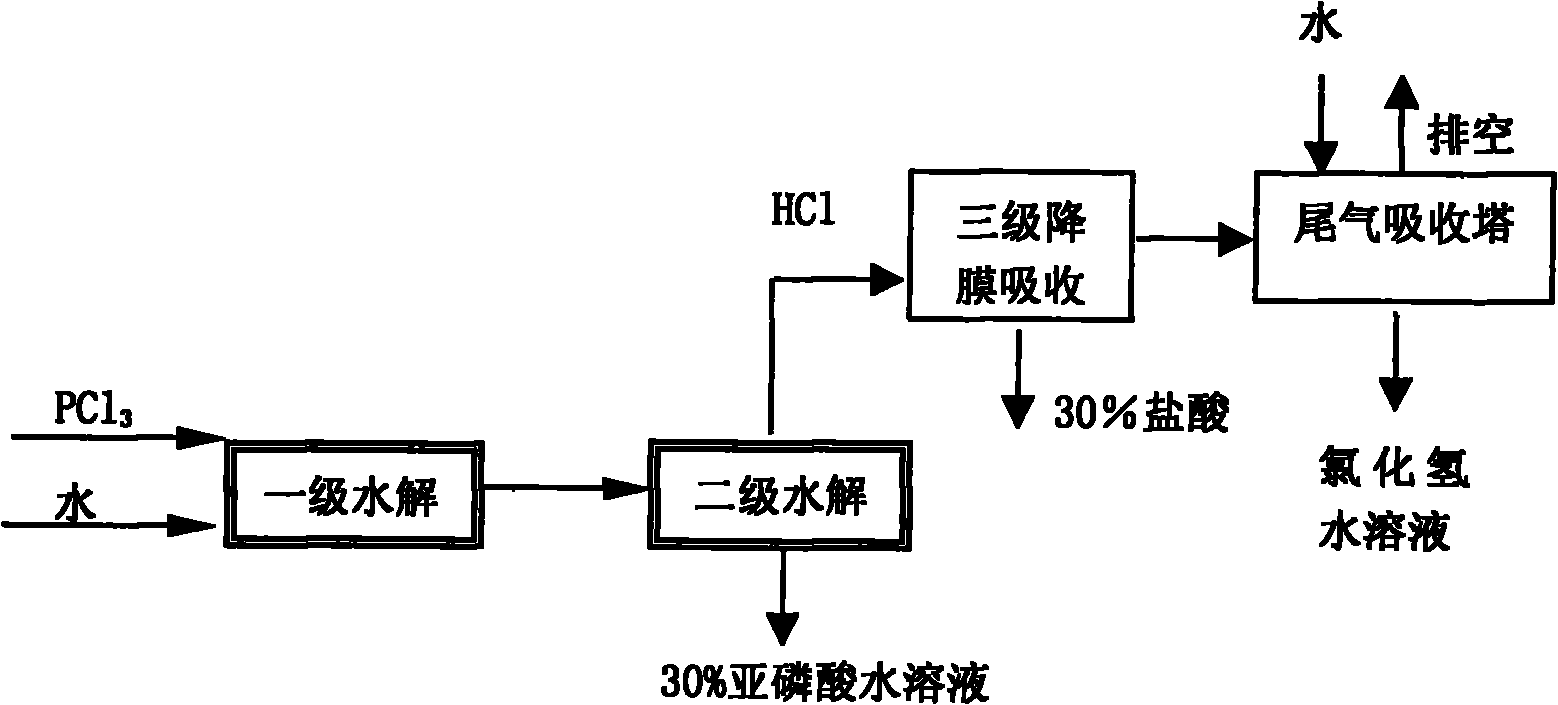

[0018] Embodiment one: at first throw 800kg content in the primary hydrolysis kettle 1 and be 45% (w / w) phosphorous acid aqueous solution as reactor base material, then add phosphorus trichloride and water two kinds of raw materials simultaneously by flow meter to The reaction is carried out in the first-stage hydrolysis kettle 1, the addition of phosphorus trichloride and water is 1500kg / h and 1250kg / h respectively, the temperature is controlled at 40°C to 60°C, and the reaction materials are overflowed from the first-stage hydrolysis kettle 1 to the second stage at the same time. Keep warm in the secondary hydrolysis kettle 2, and the temperature is controlled at 40°C to 60°C. The reaction material overflows from the top of the secondary hydrolysis kettle 2 to the finished product storage tank, and the content of the phosphorous acid aqueous solution is 45 (w / w)%. The by-product hydrochloric acid The content is 30%. Wherein the technical process includes an external cooler 3...

Embodiment 2

[0019] Embodiment two: first throw 800kg content in the primary hydrolysis kettle 1 and be 20% (w / w) phosphorous acid aqueous solution as reactor base material, then add phosphorus trichloride and water two kinds of raw materials to the primary stage simultaneously by flow meter The reaction is carried out in the hydrolysis kettle 1, the addition of phosphorus trichloride and water is 1500kg / h and 2150kg / h respectively, the temperature is controlled at 40°C to 60°C, and the reaction materials are overflowed from the primary hydrolysis kettle 1 to the secondary hydrolysis at the same time Kettle 2 is kept warm, the temperature is controlled at 40°C to 60°C, the reaction material overflows from the top of the secondary hydrolysis kettle 2 to the finished product storage tank, and the content of the phosphorous acid aqueous solution is 20% (w / w), and the content of the by-product hydrochloric acid is 30%. Wherein the technical process includes an external cooler 3, the material i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com