Permanent magnet vibration module type magnetic separator

A magnetic separator and modular technology, applied in the field of mineral processing, can solve the problems of high power consumption of electromagnetic magnetic separator, influence on popularization and application, and cumbersome operation, etc., and achieve low power consumption, simple separation process, and easy use and maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

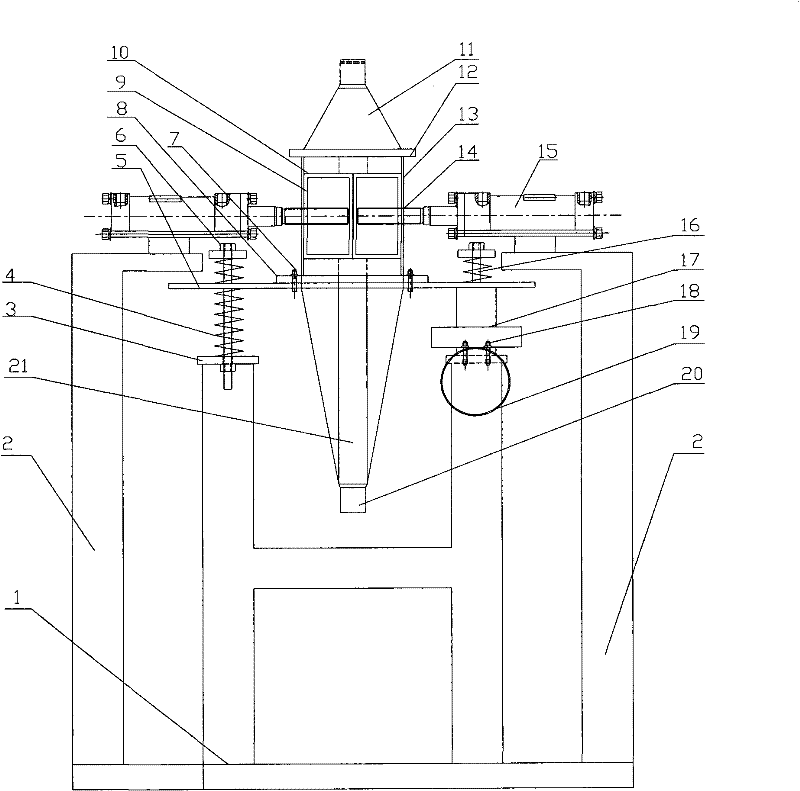

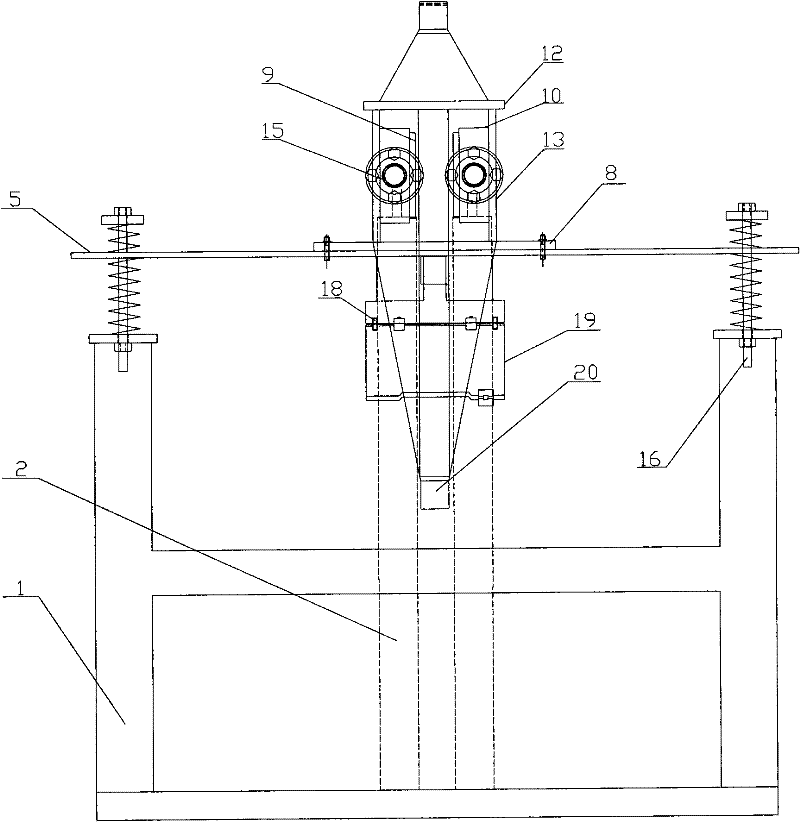

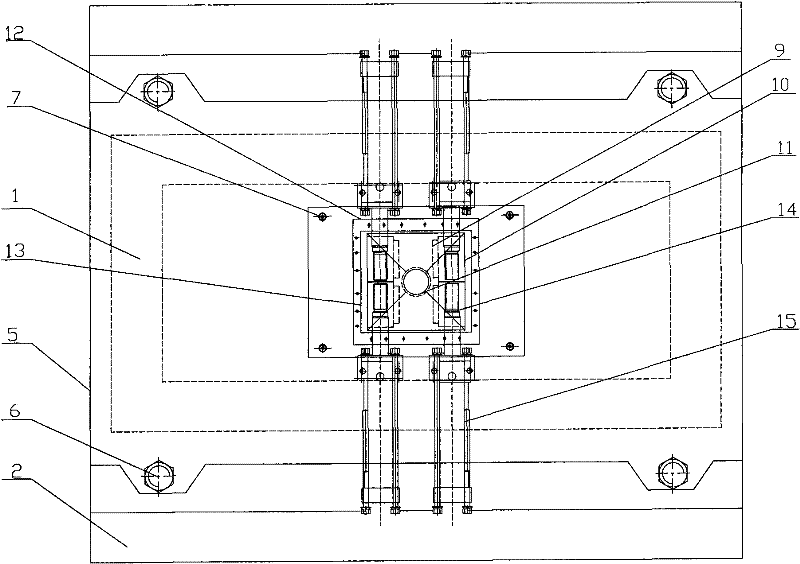

[0030] The present invention will be further described below in conjunction with the embodiments (figures):

[0031] Such as figure 1 , 2 As shown in 3, the permanent magnet vibration modular magnetic separator of the present invention includes a frame 2, and a sorting device installed above the frame 2 through a vibration mechanism. The sorting device includes a sorting chamber 13, which is located in the sorting chamber. The feed port 11 at the top, the discharge port 20 located at the top and bottom of the sorting chamber, and at least one magnetizing concentrator arranged in the sorting chamber coaxially with the sorting chamber and extending vertically downward to the discharge port. The medium box 21 is provided with a pair of permanent magnet magnets 10 capable of coaxially moving relative to the horizontal displacement on both sides of the magnetic gathering medium box 21.

[0032] The vibration mechanism of the present invention includes an elastic support member driven by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com